A Direct Drive Linear (DDL) motor is basically a rotary motor that is laid out flat and directly coupled to the driven load. By eliminating mechanical transmission components, this design delivers exceptional performance, stiffness, dynamic speeds and accelerations, positional accuracy, and throughput. DDL motors also enable compact mechanical assembly, quiet operation, zero maintenance and smooth, error-free motion.

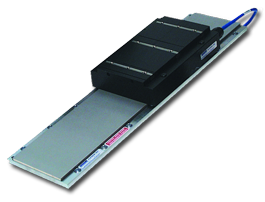

Iron core linear motors have coils wound around silicon steel laminations to maximize the generated force with a single sided magnet way. These motors’ special electromagnetic design delivers the highest rated force per size, a high Km motor constant for low thermal losses, and low cogging forces. The high thrust forces possible with these motors make them ideal for accelerating and moving high masses, and maintaining stiffness during machining and processing.

| Max. Force (N) | ||||

|---|---|---|---|---|

| Continuous | Peak | |||

| N | (lbf) | N | (lbf) | |

| IC11 | 144 to 1197 | 32.4 to 269 | 320 to 2135 | 71.9 to 480 |

| IC22 | 280 to 2393 | 62.9 to 538 | 624 to 4156 | 140 to 934 |

| IC33 | 431 to 3590 | 96.9 to 807 | 944 to 6291 | 212 to 1414 |

| IC44 | 560 to 4786 | 126 to 1076 | 1259 to 8388 | 283 to 1885 |

| ICD05 | 57 to 157 | 12.8 to 35.3 | 165 to 588 | 37.1 to 132 |

| ICD10 | 104 to 315 | 23.4 to 70.8 | 330 to 1099 | 74.2 to 247 |

| Max. Force (N) | ||||

|---|---|---|---|---|

| Continuous | Peak | |||

| N | (lbf) | N | (lbf) | |

| IC11 | 254 to 1712 | 57.1 to 385 | 315 to 2102 | 70.8 to 473 |

| IC22 | 519 to 3458 | 117 to 777 | 630 to 4204 | 142 to 945 |

| IC33 | 769 to 5135 | 173 to 1154 | 945 to 6306 | 212 to 1418 |

| IC44 | 1036 to 6916 | 233 to 1555 | 1260 to 8407 | 283 to 1890 |

Iron-less linear motors have no iron or slots for the coils to be wound on. Therefore, these motors have zero cogging, a very light, and absolutely no attractive forces between the coil assembly and the magnet way. These characteristics are ideal for applications requiring very low bearing friction, high acceleration of lighter loads, and for maximizing constant velocity, even at ultra low speeds. The modular magnet ways consist of a double row of magnets to maximize the generated thrust force and to provide a flux return path for the magnetic circuit.

| Max. Force (N) | ||||

|---|---|---|---|---|

| Continuous | Peak | |||

| N | (lbf) | N | (lbf) | |

| IL06 | 30.3 to 82.8 | 6.81 to 18.6 | 120 to 400 | 27 to 89.9 |

| IL12 | 62.1 to 148 | 14 to 33.3 | 240 to 800 | 54 to 180 |

| IL18 | 92.1 to 211 | 20.7 to 47.4 | 360 to 1200 | 80.9 to 270 |

| IL24 | 109 to 262 | 24.5 to 58.9 | 480 to 1600 | 108 to 360 |

Malaysia

Malaysia