BL1.5 BlackStone pumps have been designed to meet the ever changing needs of industry. With their broad, flat base and mounting holes for tank, shelf or floor mounting (horizontal), the pumps can be easily mounted anywhere in your plant. The rear of the pump housing also provides mounting holes to facilitate vertical mounting: wall, tank or machine. Since the pump valve assembly and controls for the unit are located on the front of the pump, there is never a problem with installation or flow adjustments.

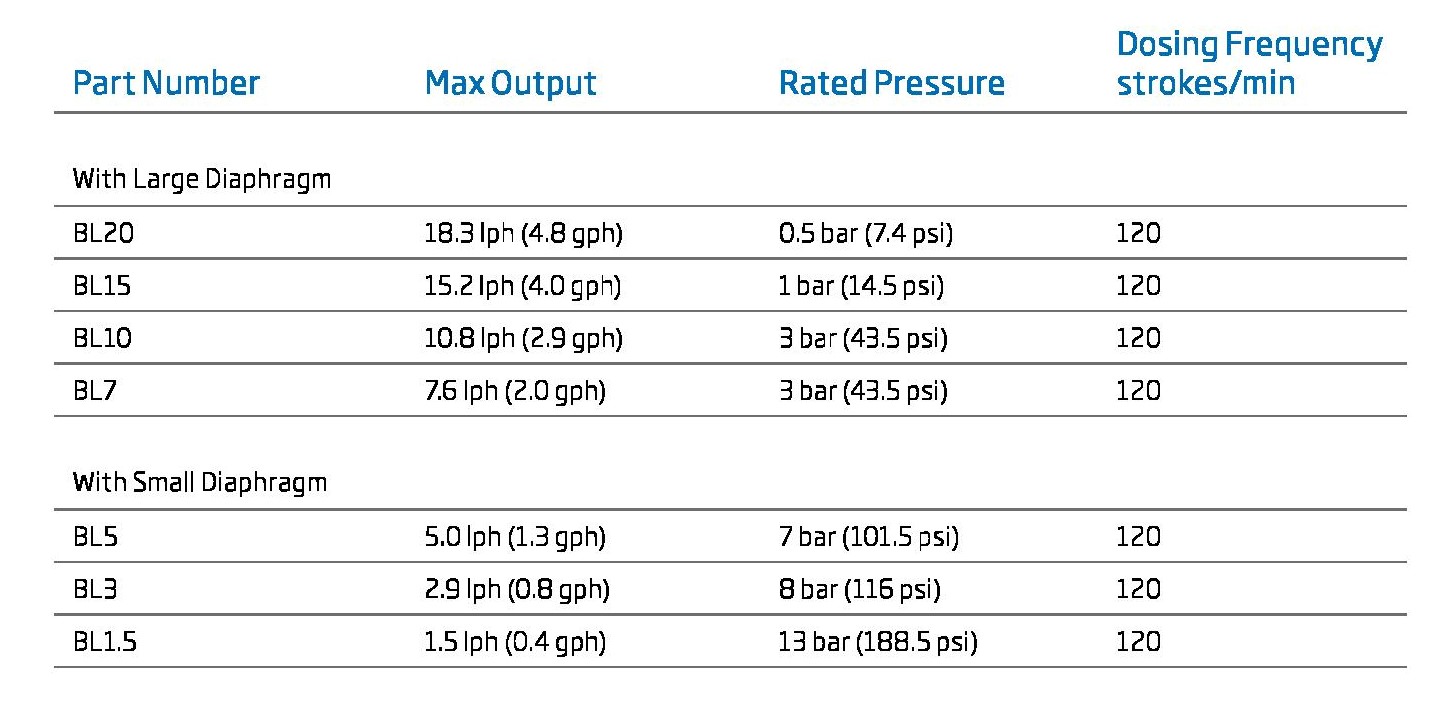

BlackStone's positive displacement solenoid driven pumps use a minimum number of moving parts, therefore reducing the chance of mechanical failure. Part wear and oiling associated with motor driven pumps (ball-bearings, gear drives and cams) are not a concern with these pumps. Blackstone pumps are more accurate than standard pumps due to the positive displacement design ensuring each stroke is identical to the strokes before and after it, thus keeping the flow rate consistent. A wide range of BlackStone pumps with different dosing capacities are available for your specific dosing needs. Each pump is supplied with disch

Simple Operation

BlackStone pumps are equipped with a single control for pump output. The external flow rate control (potentiometer) on the face of the pump allows you to adjust the

percentage of flow from 0 to 100% of the pump's rated capacity. This feature eliminates the need to worry about stroke lengths and power settings. An LED indicator lights up each time a stroke begins, allowing the user to assess the stroke rate from a distance.

High Quality Materials

BlackStone pumps have been manufactured with the highest level of mechanical precision from materials chosen for their inherent ability to resist the effects of aggressive chemicals. When you select a Blackstone pump, you are eliminating the time consuming effort involved in picking the right material for your application.

Blackstone pumps are supplied with the highest quality material as standard equipment—not optional. The diaphragm utilizes one-piece construction of PTFE, which unlike conventional laminated diaphragms, will stand up to the test of time and wear. Ball valves are constructed in glass. The pumphead and O-rings are made of PVDF, PTFE and FPM/FKM which offer unsurpassed resistance. The chemical resistance chart (right) shows how well PVDF and PTFE stand up to some of the most aggressive chemicals.

Rugged Design

Blackstone pumps are completely sealed during assembly and offer IP65 protection against splashes and spills providing excellent protection even in hostile environments. The fiberreinforced polypropylene housing stands up to aggressive chemicals while offering superior strength under tough industrial conditions .

| SKU | BL20-2 |

|---|---|

| Product Name | Blackstone 18.3 L/h Chemical Dosing Pump - BL20-2 |

| Quote Required | Yes |

| Power Consumption | approximately 200 W |

| Maximum Flow Rate | 18.3 lph (4.8 gph) |

| Dosing Pump Casing | fibre-reinforced polypropylene |

| Body Material | diaphragm in PTFE, glass ball valves and O-rings in FPM/FKM, polyethylene 5 x 8 mm tubing |

| Dosing Pumphead Materials | pumphead in PVDF (PolyVinyliDene Fluoride) |

| Self Priming | maximum self-priming height is 1.5 m (5 ft.). |

| Power Supply | 220/240; 50-60Hz |

| Environment | 0 to 50°C (32 to 122°F); RH max 95% non-condensing |

| IP Rating | IP65 |

| Dimensions | 165 x 194 x 121 mm (6.5 x 7.6 x 4.8'') |

| Weight | approx. 3 kg (6.6 lb.) |

Malaysia

Malaysia