BL122 and BL123 are designed to maintain constant pH and ORP (disinfectant) levels in swimming pools, hot tubs, and spas and offer the added benefit of allowing remote connection and access to devices via the Hanna Cloud web app. Available in two configurations, the basic version allows for direct installation of probe and chemical injection fittings into existing piping. Also available is a panel mounted version with a bypass flow cell that allows for calibration and maintenance of the probe without having to shut down the re-circulation pump.

The chlorine level is measured based on the ORP or REDOX principle. An increase of the ORP value correlates with an increase of the free chlorine level. pH and disinfectant testings are made together for more efficient disinfection and control. The efficacy of sanitizers, is dependent on a controlled pH value. The ORP value is the most consistent indicator of the sanitizing effectiveness of the pool/hot tub or water treatment. Typically 650-750 mV at 7.2 pH indicates proper water treatment (all harmful bacteria are killed in matter of seconds). pH and disinfectant testings are made using the HI1036-1802 combined electrode installed inline or in flow cell. To prevent the ground loop effects from causing erratic readings and damage to the system the electrode has a matching pin considered the “earth ground“ connection. It was specially designed to detect the broken electrode based on a shifted ISO potential value. The HI1036-1802 uses a Ag/AgCl reference with 3.5 M KCl. The ORP values are referenced to it.

Hanna Cloud is a web based application that connects you to measurement devices such as the BL122 and BL123. Measurements and data storage are accessible from your PC, tablet or phone. Multiple registered devices may be connected to Hanna Cloud.

Measurements, trends, history, device settings, alarms and messages are transmitted to your “Dashboard” as your instrument measures and controls your process.

Multiple secondary users may also be added to your device account to monitor measurements and receive email or pop-up messages from your process device.

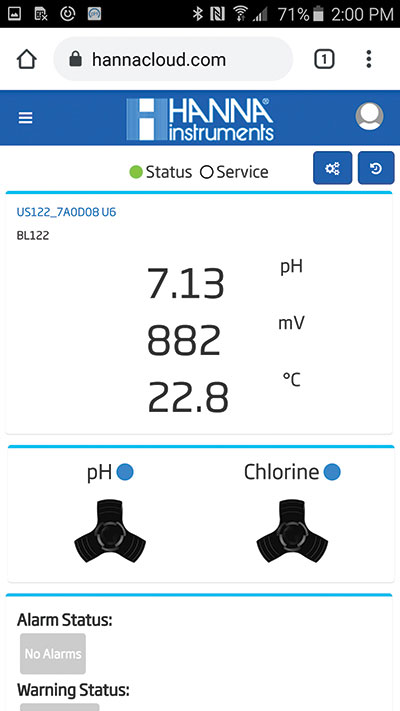

Measurement

Measurement, alarm, hold and pump status are easily viewable.

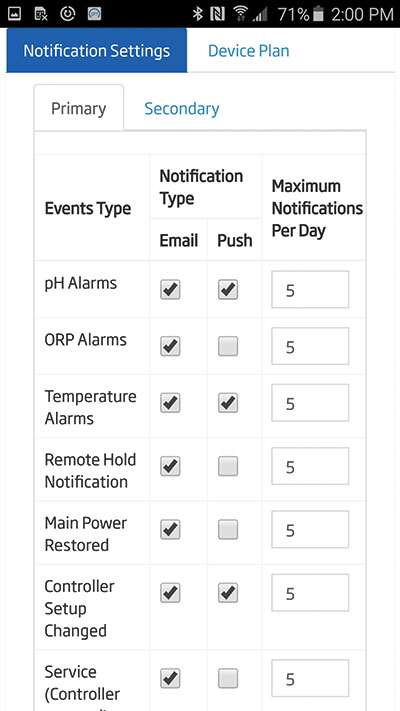

Notifications

Select which notifications you would like to receive.

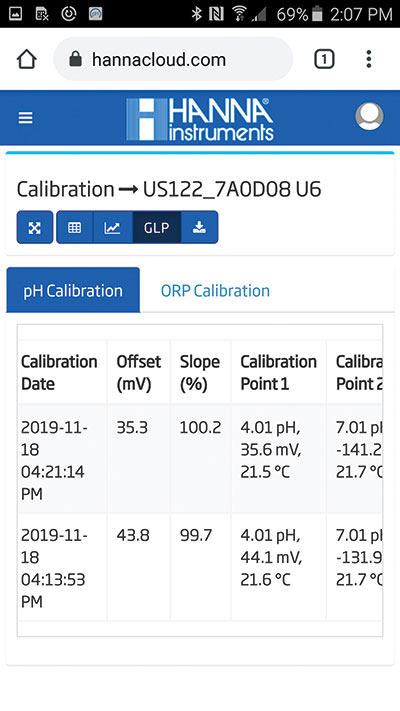

GLP

Review of GLP data including date and time of the last calibration.

Logging

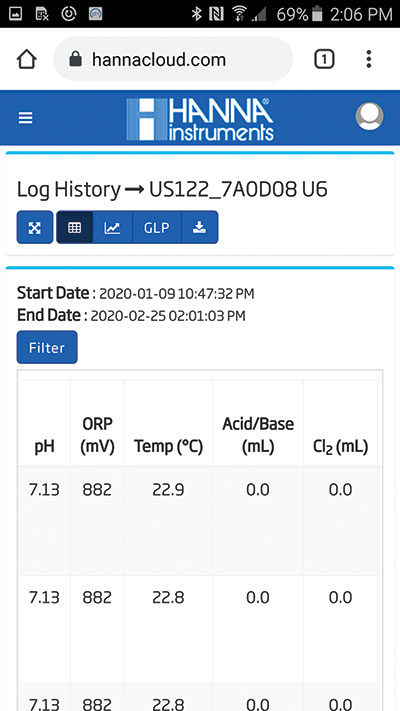

Log history in table form. Can be transferred as a PDF or csv.

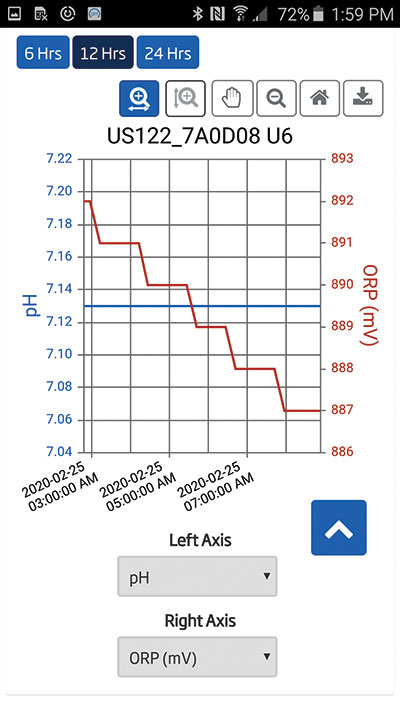

Graphing

Use a graph to view trends over the last 12 hours or change to a specific time period.

The BL122 and BL123 are equipped with two peristaltic dosing pumps with replaceable chemical resistant tubing. When using a diaphragm pump, chlorine gas formed from outgassing can collect in the pump head resulting in the pump losing its prime; the buildup of chlorine gas is not a problem with peristaltic pumps that use rollers and tubing.

Pool LIne controllers feature proportionally controlled dosing pumps. Based on the sensitivity of the process to chemical addition, these controllers allow the user to adjust a proportional band. This setting determines the amount of time that the pumps are dosing as a percentage of the deviation from the set point allowing for very fine control in maintaining the desired set point.

The flow rate from the dosing pumps is adjustable from 0.5 to 3.5L/h. Larger bodies of water require more chemical to be dosed than small bodies since it takes more chemical to realize a change in the reading. The adjustable flow rate, like the proportional band, allows for better control in maintaining a desired set point.

With chlorine disinfection there is an inverse relationship between pH and ORP. As the pH level increases, the ORP level decreases. The BL120 utilizes a dosing consent feature that will not dose chlorine until the pH value is first corrected since it is possible to have a low ORP value even though there is sufficient chlorine. The dosing consent feature prevents wastage of chemicals and avoids a higher than necessary chlorine concentration.

An inline flow switch or a mechanical relay connected to the re-circulation pump power source may be connected to the hold input of the Pool Line controller. With no flow or when no power is applied to the re-circulation pump, the hold circuit disables the dosing pumps. This will prevent any dosing of chemical when there is no movement of water in the system.

The versatile display of the BL122 and BL123 allows for three screen modes. The LCD can display all three parameters at one time, a 3-second cycle of single parameters, or a real-time plot screen with options for parameter selection, zooming, and log recall.

Hanna controllers allow users to enable or disable the low and high level of alarms for all parameters. When an alarm is activated, all dosing will stop. The alarm system also offers overdosing protection if the value is not corrected within a specified time interval then the meter will go into alarm status.

The Pool LIne cloud controllers offer multiple LED indicators for status, servicing, and pump operation. The STATUS LED changes color based on operational state; green when setting are in range, yellow when user intervention is required, and red for problems. The SERVICE LED indicates any alarms and process errors experienced by the controller.

The readings for each parameter are automatically logged every 10 seconds. A new log is started each time the instrument is calibrated or at the start of a new day. Logged data include pH, ORP, and temperature values, last calibration data, setup configuration, and any event data. Each log is saved as a .csv file for easy transfer.

For review and storage the users can easily transfer data to a PC using a flash drive and the USB port.

Hanna’s BL122 and BL123 controllers feature a password protection solution that offers restricted access to calibration, setup, and review of logged data. The password can be set and enabled/disabled during general setup of the instrument.

The controller is available in one of two configurations: an in-line model which allows for direct installation of the probe and chemical injection fittings into existing piping (BL122-10 & BL123-10) or a panel mounted system with a bypass flow cell (BL122-20 & BL123-20). The bypass flow cell allows for calibration and maintenance of the probe without having to stop the recirculation pump.

The HI1036-1802 is a digital probe that measures pH, ORP, and temperature. This probe also incorporates a potential matching pin. The pin is considered the “earth ground” connection and is used to prevent ground loop effects from causing erratic readings and damage to the system.

| SKU | BL122-web |

|---|---|

| Product Name | Cloud Enabled Swimming Pool Controller with Built-in Dosing Pumps |

| Quote Required | Yes |

| pH Range | 0.00 to 14.00 pH |

| pH Resolution | 0.01 pH |

| pH Accuracy | ±0.05 pH |

| pH Calibration | pH buffer calibration |

| pH Temperature Compensation | Automatic -5.0 to 105.0 ºC (23.0 to 221.0 ºF) |

| ORP Range | ±2000 mV |

| ORP Resolution | 1 mV |

| ORP Accuracy | ±5 mV |

| Temperature Range | -5.0 to 105.0 ºC (23.0 to 221.0 °F) |

| Temperature Resolution | 0.1 °C (0.1 ºF) |

| Temperature Accuracy | ±1 ºC (±1.8 ºF) |

| Dosing Control |

Proportional feed using adjustable set point and adjustable proportional band. Delay to start at power-on and overdosing protection using. Over feed safety timer. |

| Consent Relay | pH dosing interlocked with ORP |

| Alarm Relay Set Point |

High and Low with enable/disable option for all parameters. Alarm is triggered for 5 consecutive readings over/under threshold. |

| Over Dosing Control | Over feed safety timer. |

| Analog Ouput Signal |

4 to 20 mA (3), sourcing, configurable Output impedance ≤ 500 Ohm Accuracy < 0.5 % FS Galvanically isolated up to 50 V relative to earth Analog outputs only available with BL123-10 and BL123-20 |

| Digital Input Signal |

Galvanic isolated, powered contact type Low level in acid/base tank (contact open) Low level in chlorine tank (contact open) Hold input (contact open) |

| Power Consumption | 10 VA |

| Multi-parameter Probe | HI1036-18XX (02, 05, 10, 15, 20 m of cable) pH/ORP/Temperature with matching pin combined digital probe |

| Logging Type | Automatic Log of measurements (pH, ORP, Temperature) and events |

| Logging Memory | 60 days logging with 10 s period (or 100 logs) |

| Connectivity | USB |

| GLP | pH/ORP |

| Power Supply | 100 - 240 VAC |

| Environment | 0-50 ºC (32-122 ºF) Max 95% RH non-condensing |

| Dimensions |

245 x 188 x 55 mm (73 mm with pumps) 9.6 x 7.4 x 2.2” (2.9” with pumps) |

| Weight | 1700 g (60 oz) |

| Ordering Information | In-Line Configuration |