hard and versatile: Smoothing and work-hardening in new dimensions

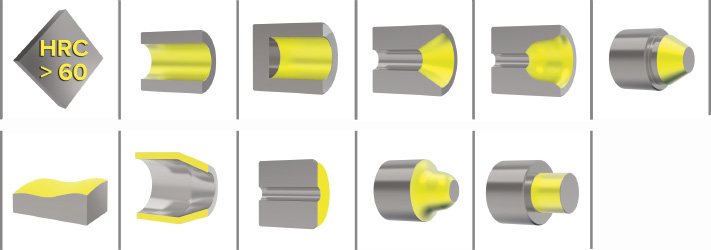

Diamond-burnishing tools expand the range of applications of roller burnishing technology, as even hardened materials up to approximately 60 HRC can be roller burnished.

In the process, a high-precision, micropolished diamond glides over the surface. As soon as the yield point of the material is exceeded, the profile peaks of the workpiece surface flow into the adjacent recesses in the µm range.

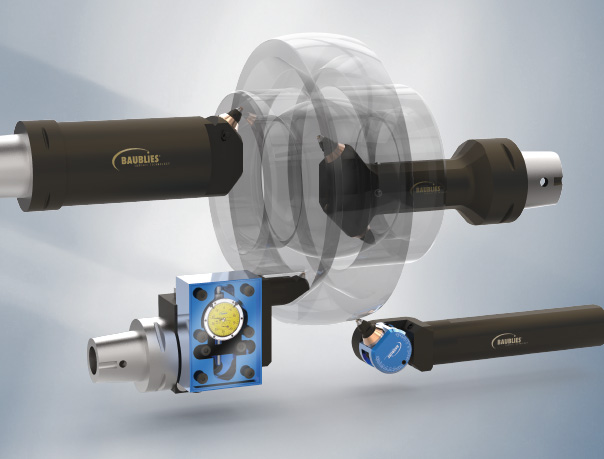

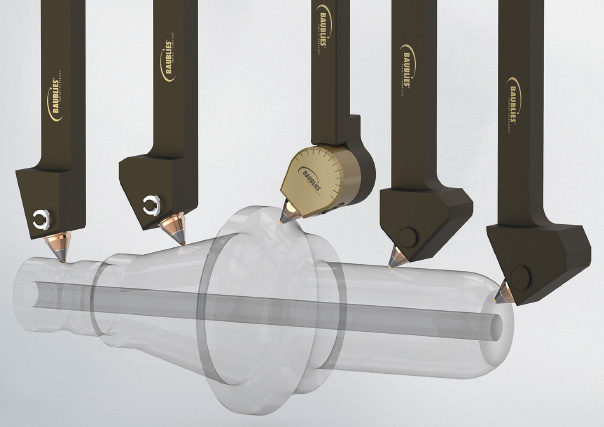

Compared to the machining by means of rollers, the contact area between the workpiece and the diamond is much smaller. Therefore, plastic cold working with a reduced influence of force can take place. Baublies diamond roller burnishing tools advance into hardness and diameter areas in which conventional roller burnishing tools cannot be used due to the workpiece characteristics or geometry. With diamond-burnishing tools, all contours – internally and externally – can be roller-burnished and deep-rolled.

Malaysia

Malaysia