► No wearing parts (carbon brushes, commutator, field coil)

The brushless motor offers a significantly extended product life cycle by eliminating trouble including armature burnout, layer short or commutator wear even in severe work environments. Besides, no carbon brush replacement is required.

More Torque. More Power.

The max tightening torque is 305Nm for the 18V WR18DBDL2 and 285Nm for the 14.4V WR14DBDL2.

The overall length is 145mm, which is 23mm shorter than that of our conventional models

Longer Runtime per Charge (Approx.)

When loosening M20 high-tension bolts tightened at 350 Nm.

Tightening Mode Settings

The tightening torque depends on the material, size and class of the bolt. Make a test fastening to adjust the mode setting to suit the bolt.

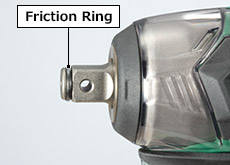

The friction ring holds a socket on the anvil, making it easier to install a pin and O-ring to securely lock the socket in place.

The rear fan efficiently cools down the motor and hammer case for more durability.

Less user fatigue due to the well-balanced design with the center of gravity positioned at the middle finger of the grip hand.

Thanks to the unique design of dust-protective cooling windows and fully plastic coating on some important inner parts, this product conforms to IP56 protection class ratings (dust and water resistance) for electrical equipment as stipulated by the international IEC regulations.

allows for finer adjustments in the low speed range. It is also more efficient in transferring energy resulting in longer tool life.

Our Original Brushless Motor Technology

► Our original compact controller

Long Lifetime, Maintenance-Free

Powerful

The torque is increased by 55Nm (18V) and 50Nm (14.4V) respectively, compared to our conventional models (WR18DBDL, WR14DBDL).

Compact Design for Better Handling

(WR18DBDL/WR14DBDL).

Highly Efficient

Tightening Mode Selector for a Variety of Applications

Mode

Low

Medium

High

Single

Tightening Mode Indicator Lamp

Applications

Light load work

Installing pipe supports, scaffolding, etc.

Heavy load work

Assembling steel frames, etc.

Delicate work

Tightening small diameter screws, etc.

Smooth Socket Changes with a Friction Ring Anvil

Note : It is possible to temporality hold the socket in place with the friction ring, but be sure to insert the pin and attach the O-ring before use. If the power tools is used while the socket is temporarily held in place, the socket may fall off and cause an injury.

Newly Designed Airflow System for Optimal Cooling Efficiency

Well-Balanced Weight Distribution for Better Work Efficiency

Dust and Water Resistant

Smooth Control Electronic Switch

Built-in cooling system of the UC18YSL3 charger reduces charging time by efficiently cooling both the battery and charger at the same time during charging.

* Included batteries vary by country or area.

| Model | WR18DBDL2 | |

|---|---|---|

| Capacity | Bolt | M10 - M20 (3/8 - 3/4'') |

| High Tension Bolt | M10 - M16 (3/8 - 5/8'') | |

| Squire Drive | 12.7mm (1/2'') | |

| Tightening Torque | 305Nm (225ft-lbs.) | |

| Battery Voltage | 18V | |

| No Load Speed | High Mode | 0 - 2,700/min |

| Medium Mode | 0 - 2,000/min | |

| Low Mode | 0 - 1,000/min | |

| Single Mode | 0 - 2,700/min | |

| Full Load Impact Rate | 0 - 3,600/min | |

| Overall Length | 145mm (5-11/16'') | |

| Weight *1 |

1.8kg (4.0lbs.) with BSL1860, BSL1850, BSL1830 1.5kg (3.3lbs.) with BSL1830C |

|

|

Vibration Total Values (triax vector sum) *2 |

Vibration Emission Value = 11.7m/s2 Uncertainty K = 1.5m/s2 |

|

| Standard Accessories *3 | 2 Batteries (BSL1860, BSL1850, BSL1830 or BSL1830C), Charger (UC18YFSL, UC18YSL3 or UC18YML2) | |

| Battery Cover, Carrying Case | ||

Notify the transporting company that a package contains a lithium-ion battery, inform the company of its power output and follow the instructions of the transportation company when arranging transport.

Malaysia

Malaysia