Specifications

- Ambient operation temp. max: 60 °C

- Ambient operation temp. min: -40 °C

- Cable material detail: PVC

- Cable material: plastic

- Certificate: cULus certificate, Photobiological safety (DIN EN 62471) certificate, MAR declaration of conformity, ECOLAB certificate, ACMA declaration of conformity, EU declaration of conformity, UK declaration of conformity, China-RoHS, IO-Link

- Communication Interface detail: V1.1, COM2 (38,4 kBaud)

- Communication interface: -, IO-Link, Bluetooth

- Connection type Detail: Cable with M12 male connector, 4-pin, Cable, 4-wire, male connector M12, 4-pin, Cable with Q6 male connector, 6-pin, DC-coded, cable, 5-wire, male connector M12, 5-pin

- Connection type: cable, cable with male connector, male connector

- Current consumption: 30 mA, ≤ 30 mA

- Delay time: 30000 ms

- Dimension (depth): 42 mm

- Dimension (length): 55.7 mm

- Dimension (width): 20 mm

- Enclosure rating: IP65, IP69, IP66, IP67

- Functional principle detail: Foreground suppression, LineSpot technology, Without reflector minimum distance (autocollimation/coaxial optics), ClearSens, Background suppression, TwinEye technology, With minimum distance to reflector (dual lens system), MultiPulse, NarrowBeam

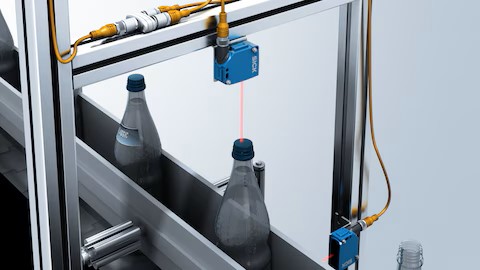

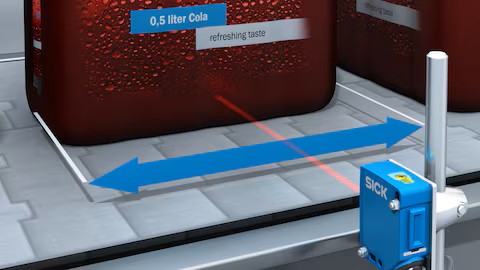

- Functional principle: Photoelectric proximity sensor, Photoelectric retro-reflective sensor, Through-beam photoelectric sensor

- Housing material detail: VISTAL

- Housing material: plastic

- Housing: rectangular

- Items supplied: 1 x WLA16P-24162100A00 , 1218660, cable YF2Z14-100XXXXLEAX , 6027559, mounting bracket BEF-SG-W16/W26 , 2123991 with screws and washers, PL40A reflector , 1012720, pre-assembled on a BEF-MPPL40/PL80 mounting plate , 2123993, 4 x screws, sliding nuts, 1218660, mounting bracket BEF-SG-W16/W26 , Mounting bracket BEF-AP-W16B, Mounting bracket BEF-AP-W16

- Length of cable: 270 mm, 2 m, 140 mm, 10 m, 5 m

- Light sender detail: PinPoint LED, LED

- Light source: LED

- Light spot size: 6 mm (500 mm), 12 mm (800 mm), 80 mm (5 m), 8 mm (300 mm), 600 mm x 600 mm (20 m), 90 mm (8 m), 13 mm x 13 mm (300 mm), 3 mm (200 mm), 5 mm (250 mm), 4 mm x 4 mm (200 mm), 16 mm (1 m), 3 mm x 30 mm (200 mm), 110 mm (8 m)

- MTTFD: 420 a, 548 a, 626 a, 629 a, 539 a, 538 a, 690 a, 419 a, 2009 a, 524 a, 507 a, 627 a, 378 a

- Number of digital outputs: 1, 2

- Object distance (max.): 400, 10000, 300, 500, 9500, 60000, 1000, 5000, 45000, 750, 1900, 14000, 1350, 1600, 250, 900, 600, 650, 1500 mm

- Object distance (min.): 0, 400, 50, 250, 10, 2000 mm

- Product family: W16

- Product segment: Photoelectric sensors

- Response time: ≤ 1.4 ms, ≤ 2.5 ms, ≤ 500 s, ≤ 0.1 s, ≤ 330 s, ≤ 3.3 ms

- Sensing range max.: 7 ... 12 m

- Sensing range: 10 m

- Setting Method: , for inverting the switching function (light/dark switching), for configuring the sensor parameters and Smart Task functions, for configuring the time function, for sensitivity adjustment, Teach-in plus user mode selector, For setting the sensing range, for activating the test input

- Shape of light spot: Point-shaped, Line-shaped, rectangular

- Signal voltage NPN HIGH/LOW: approx. UB / < 2.5 V

- Signal voltage PNP HIGH/LOW: approx. VS 2.5 V / 0 V, Approx. UB-2.5 V / 0 V

- Smart Sensor: efficient communication, diagnosis, Smart Task, Enhanced Sensing

- Smart Task name: base logics, Counter + debouncing

- Special applications: Detecting objects wrapped in film, Detecting perforated objects, Detecting transparent objects, Detecting uneven, shiny objects, Detecting flat objects

- Special features: line-shaped light spot, Dynamic blind zone 50 mm ... 75 mm, Factory setting: Switch-off delay, 10 ms, differs from the IODD (document no. 8021068), Factory setting: sensing range 125 mm, Factory setting: sensing range 505 mm, light switching (pre-setting), Factory setting: Switch-off delay, 10 ms, differs from the IODD (document no. 8021052), Oscillating output 10 Hz (object present), Factory setting: Switch-on delay, 10 ms, differs from the IODD (document no. 8021068), Factory setting: sensing range 205 mm, Factory setting: sensing range 405 mm, Factory setting: sensing range 305 mm, Teach-Turn adjustment deactivated, Dynamic blind zone 50 mm ... 73 mm, Factory setting: sensing range 350 mm, MultiPulse: sensor with self-monitoring, Factory setting: sensing range 300 mm, 1 x WLA1616P-24162100A00 1218660, with cable 6027559, mounting bracket 2123991, with screws and washers, PL40A 1012720, pre-assembled on a mounting bracket 2123993, 4 x screws, sliding nuts for mounting on ITEM profile, Factory setting: sensing range 650 mm, Factory setting: sensing range 650 mm, pre-mounted on BEF-AP-W16, 2095677, Factory setting: sensing range 400 mm

- Sub product family: WLG16, WSE16, WTF16, WTS16, WTL16, WTB16, WLA16, WLD16

- Switching frequency: 1000 Hz, 350 Hz, 200 Hz, 1500 Hz, 10 Hz, 150 Hz

- Switching mode: Light switching, Light/dark switching, Dark switching

- Switching output detail: push-pull: PNP/NPN, PNP

- Switching output: PNP, Push-pull

- Task: Detecting - Transparent objects, Detecting - Standard objects, Detecting - Perforated objects

- Type of digital output: Complementary

- Type of light: visible red light, Infrared light

- Voltage type: DC

- Weight: ca. 100 g, ca. 140 g, ca. 200 g, 50 g, ca. 50 g, ca. 70 g

- Time functions: off delay (factory setting), ON and OFF delay, deactivated (factory setting), switch-on delay, Impulse (one shot), deactivated, on delay (factory setting), off delay

详情

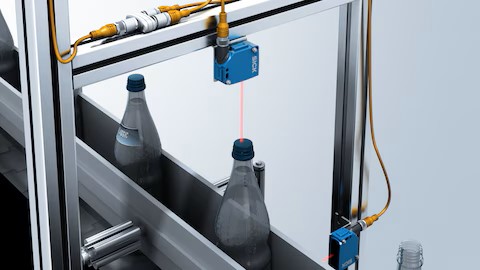

The highflier in object detection

The W16 is equipped with new technologies such as TwinEye, LineSpot, ClearSens and OptoFilter for reliable object detection. It can be quickly and conveniently adjusted via the BluePilot operating and display concept. Since every W16 is designed as a Smart Sensor, it can be configured to fit the application via IO-Link and offers additional diagnostic functions and Smart Tasks. It is therefore a trailblazer on the path to Industry 4.0. The highly-visible PinPoint LED and the infrared LED are available as the light source. The durable laser inscription ensures device identification in the long run. Thanks to the very rugged VISTAL® housing and the predictive maintenance, the W16 offers very high reliability and prevents unplanned machine downtimes.

W16 AT A GLANCE

Benefits

-Usability and uniform operation thanks to optical quality display on the housing or conveniently via IO-Link

-Simplification when aligning the light beam to the reflector, the receiver or to an object thanks to the highly-visible light spot of the PinPoint LED combined with the optical LED display

-Very high reliability thanks to new detection technologies as well as high optical ruggedness

-The Smart Sensor makes machine processes quicker, more efficient and transparent, enables predictive maintenance and is thereby a trailblazer for Industry 4.0 applications

Features

-Technologies: ClearSens, LineSpot, TwinEye, OptoFilter

-BluePilot: Optical alignment aid, adjustment of the sensing range via Teach-Turn adjustment with optical sensing range indicator or via IO-Link

-PinPoint LED: Light-intensive red sender LED

-Smart Sensor: Enhanced Sensing, IO-Link, Diagnostics, Smart Tasks

-Vistal housing: High chemical, thermal and mechanical resistance

ADVANTAGES

Easy and quick sensor alignment using BluePilot

Easy and quick sensor alignment using BluePilot

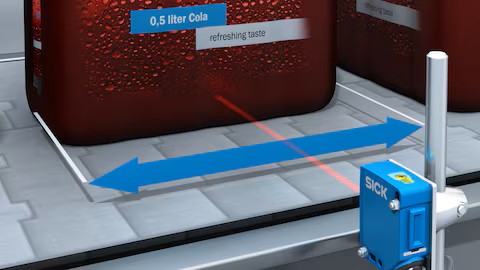

Using the innovative BluePilot alignment aid, the sensors in the W16 and W26 product family can be commissioned in seconds. The blue LED display provides direct feedback to assist you with optimally aligning the sensors and reflectors as well as senders and receivers. In the case of the photoelectric proximity sensors, a push-and-turn mechanism enables the sensor to be adjusted quickly and precisely, thereby eliminating the customary time-consuming fine adjustment using rotary controls.

BluePilot also reports any change in detection quality, e.g., due to contamination or vibrations, which ensures faults are detected in a timely manner, long before a production downtime occurs.

Photoelectric retro-reflective and through-beam photoelectric sensors

The blue LED alignment aid speeds up the process of optimally aligning the sensors and reflectors or senders and receivers,Any changes in the operational safety due to contamination or vibrations can be recognized at a glance

Photoelectric proximity switch

2 in 1: The combination of teach-in button and potentiometer in one control element enables intuitive fine-tuning in a matter of seconds,The visual representation of the sensing range allows you to maintain an overview at all times

Photoelectric retro-reflective sensor for detecting transparent objects

Select the right mode for the object type in question by simply rotating the control element

With the new BluePilot operating concept, you will save valuable time commissioning the sensor, and avoid production downtimes thanks to the timely reporting of faults.

Rugged and reliable

Rugged and reliable

The sensors from the W16 product family are particularly rugged and reliable.

If optical contamination exists on the sensor or reflector and after cleaning, the sensors automatically adjust their switching thresholds thanks to AutoAdapt, meaning they always keep a clear view. With the OptoFilter, the sensors see what they have to see: they are immune to LED lights, reflections from safety vests and the influence of depolarizing objects.

The sensors can also withstand many chemical, thermal and mechanical environmental influences thanks to the ultra-rugged VISTAL housing.

Everything reliably detected

Thanks to the OptoFilter, the sensors feature high ambient light immunity.

If there is contamination, the W16 sensors automatically adjust their switching thresholds.

Thanks to the VISTAL housing, the sensors can also withstand extreme loads.

The rugged design ensures high system availability and reduces downtimes.

.jpg) Smart sensors for efficient machine communication

Smart sensors for efficient machine communication

Smart Sensors provide indispensable input for every process chain. They support dynamic, real-time-optimized, and self-organized industry processes. The Smart Sensors W16 and W26 capture real-life situations, and generate and receive data and information beyond traditional switching signals or measured process parameters.

From raw signals to customized information

Base logic: User-definable logic functions with trigger sensors and switching signal delays

Time measurement and debouncing with the aid of the Time Measurement and Debouncing Smart Task

W16 with the Counter and Debouncing Smart Task counts and evaluates detection signals

Interconnectivity and efficient processing of data ensure leaner structures and cost benefits for your process.

更多 Truserv Technologies (M) Sdn Bhd 相关资料

Easy and quick sensor alignment using BluePilot

Easy and quick sensor alignment using BluePilot

Rugged and reliable

Rugged and reliable

.jpg) Smart sensors for efficient machine communication

Smart sensors for efficient machine communication

Malaysia

Malaysia