Specifications

- Ambient operation temp. max: 60 掳C

- Ambient operation temp. min: -40 掳C

- Beam separation: 99 mm, 111 mm, 10 mm, 142 mm, 96 mm, 120 mm, 134 mm, 93 mm, 143 mm, 170 mm, 101 mm, 121 mm, 104 mm, 85 mm, 130 mm, 72 mm, 150 mm, 152 mm, 108 mm, 180 mm, 200 mm, 51 mm, 86 mm, 138 mm, 100 mm, 145 mm, 50 mm, 110 mm, 75 mm, 162 mm, 184 mm, 115 mm, 137 mm, 82 mm, 165 mm, 70 mm, 117 mm, 65 mm, 125 mm, 127 mm, 69 mm, 105 mm, 135 mm, 133 mm, 160 mm, 168 mm, 90 mm, 95 mm, 92 mm, 109 mm, 94 mm, 103 mm, 55 mm, 116 mm, 155 mm, 84 mm, 106 mm, 102 mm, 140 mm, 60 mm, 87 mm, 159 mm, 151 mm, 128 mm, 131 mm, 80 mm, 118 mm

- Cable material detail: PVC, PUR

- Cable material: plastic

- Certificate: EU declaration of conformity, ACMA declaration of conformity, China-RoHS, cULus certificate, UK declaration of conformity

- Connection type Detail: cable with male connector M8, 4-pin, snap, Cable with WAGO terminal 733-104, 4-pin, cable with Stocko-connector (MKF-13264), Cable, 4-wire, Cable with MOLEX-connector 43025-0400, 4-pin, Cable with M8 special connector, 4-pin, Cable with connector M8, 3-pin, cable with connector RJ12, 6-pin, Cable with connector M8, 4-pin, with knurled nut, Cable with connector M12, 4-pin, with knurled nut

- Connection type: cable with male connector, cable

- Current consumption: 8 mA, 15 mA, 32 mA, 38 mA, 17 mA, 23 mA, 25 mA

- Dimension (depth): 17 mm

- Dimension (length): 20.3 mm

- Dimension (width): 920, 420, 1198, 750, 1073, 464, 462, 682, 914, 320, 760, 762, 380, 409, 810, 540, 864, 786, 458, 400, 620, 635, 848, 376, 457, 517, 910, 711, 710, 411, 618, 614, 650, 900, 474, 891, 820, 330, 1143, 611, 863, 465, 662, 417, 669, 617, 360, 610, 860, 295, 800, 1020, 713, 609, 472, 340, 310, 556, 500, 390, 250, 607, 600, 625, 510, 840, 345, 1200, 586, 486, 559, 755, 842, 850, 720, 825, 520, 636, 550, 685, 690, 350, 440, 640, 475, 859, 555, 480, 410, 660, 386, 200, 725, 672, 460, 358, 664, 570, 425, 655, 469, 525, 856, 450, 1000, 490, 768, 560, 300, 615, 700, 404, 561 mm

- Distance from 1st beam to leading edge of housing (including end cap): 131 mm, 80 mm, 129 mm, 220 mm, 215 mm, 159 mm, 151 mm, 102 mm, 140 mm, 213 mm, 146 mm, 103 mm, 119 mm, 95 mm, 57 mm, 92 mm, 114 mm, 59 mm, 171 mm, 109 mm, 94 mm, 105 mm, 183 mm, 74 mm, 168 mm, 90 mm, 70 mm, 65 mm, 117 mm, 588 mm, 88 mm, 125 mm, 127 mm, 135 mm, 69 mm, 115 mm, 137 mm, 82 mm, 165 mm, 153 mm, 145 mm, 58 mm, 50 mm, 110 mm, 75 mm, 66 mm, 86 mm, 138 mm, 76 mm, 100 mm, 113 mm, 148 mm, 150 mm, 180 mm, 108 mm, 51 mm, 250 mm, 130 mm, 101 mm, 112 mm, 139 mm, 91 mm, 78 mm, 85 mm, 161 mm, 96 mm, 120 mm, 71 mm, 63 mm, 123 mm, 143 mm, 99 mm, 231 mm, 266 mm, 237 mm, 73 mm

- Enclosure rating: IP67

- Functional principle detail: Energetic

- Functional principle: Photoelectric proximity sensor

- Housing material detail: Aluminum (anodised)

- Housing material: metal

- Length of cable: 500 mm, 300 mm, 150 mm, 2000 mm, 1500 mm, 2500 mm, 3000 mm, 800 mm, 1000 mm, 100 mm

- Light sender detail: LED

- Light source: LED

- Light spot size: 27 mm x 29 mm (45 mm)

- Mounting system type: BEF-AP-RSBHEX, Hex adapter bracket, BEF-AP-RSBADHA, 8 mm round adapter bracket with adhesive back, BEF-AP-RSBCON, adapter bracket to snap between hex sections, BEF-AP-RSBADHB, adapter bracket with adhesive back, none

- Number of beams: 5, 6, 2, 8, 4, 7, 3

- Object distance (max.): 300 mm

- Object distance (min.): 2 mm

- Product family: Roller Sensor Bar

- Product segment: Photoelectric sensors

- Response time: ≤ 1 ms

- Shape of light spot: Point-shaped

- Signal voltage NPN HIGH/LOW: approx. UB / < 2.5 V

- Signal voltage PNP HIGH/LOW: Approx. UB-2.5 V / 0 V

- Smallest detectable object (MDO) typ.: 106, 131, 50, 121, 127, 160, 101, 200, 180, 60, 111, 69, 231, 118, 135, 213, 171, 125, 75, 165, 90, 100, 237, 155, 73, 85, 103, 99, 150, 108, 104, 168, 162, 120, 588, 96, 250, 183, 105, 184, 220, 102, 65, 80, 117, 140, 92, 133, 159, 215, 138, 70, 109, 153, 170, 128, 139, 93, 134, 129, 110, 115, 145, 86, 151, 148, 143, 130, 95, 82, 266, 137 mm

- Special applications: Detecting flat objects, Detecting uneven, shiny objects, Detecting objects with position tolerances, Detecting perforated objects

- Special features: connection type with external diameter: 7.85 mm +0.1 mm / -0.2 mm and min. IP54, Type with T-slot, Sensing range preset: 100 mm on white

- Switching frequency: 500 Hz

- Switching mode Q1: Dark switching, Light switching

- Switching mode Q2: Dark switching, Light switching

- Switching mode: Light/dark switching, Dark switching, Light switching

- Switching output detail: PNP, push-pull: PNP/NPN, PNP: open collector, NPN, NPN: open collector

- Switching output Q1: NPN: open collector, PNP, NPN, PNP: open collector, push-pull: PNP/NPN

- Switching output Q2: PNP, not connected, push-pull: PNP/NPN, PNP: open collector, NPN

- Switching output: PNP, NPN, Push-pull

- Task: Detecting - Standard objects, Detecting - Perforated objects

- Type of digital output: Complementary

- Type of light: Infrared light

- Weight: ca. 190.7 g, ca. 230.5 g, ca. 240.3 g, ca. 171.5 g, ca. 263.1 g, ca. 305.5 g, ca. 237.8 g, ca. 199.7 g, ca. 168.9 g, ca. 196.1 g, ca. 163.5 g, ca. 299.3 g, ca. 311.7 g, ca. 212.8 g, ca. 207 g, ca. 247.5 g, ca. 130.9 g, ca. 166 g, ca. 174.4 g, ca. 275.8 g, ca. 278.7 g, ca. 154.4 g, ca. 221.8 g, ca. 258.8 g, ca. 223.3 g, ca. 225.1 g, ca. 276.5 g, ca. 181.6 g, ca. 224 g, ca. 120 g, ca. 242.8 g, ca. 313.1 g, ca. 176.5 g, ca. 125.4 g, ca. 203.7 g, ca. 250.4 g, ca. 148.6 g, ca. 167.8 g, ca. 152.6 g, ca. 123.6 g, ca. 435.2 g, ca. 188.8 g, ca. 258 g, ca. 187.8 g, ca. 313.5 g, ca. 140.3 g, ca. 254.1 g, ca. 217.8 g, ca. 170.4 g, ca. 290.3 g, ca. 172.2 g, ca. 203 g, ca. 151.5 g, ca. 333.8 g, ca. 414.6 g, ca. 239.6 g, ca. 304.8 g, ca. 272.2 g, ca. 220.4 g, ca. 434.5 g, ca. 166.4 g, ca. 293.9 g, ca. 331.6 g, ca. 159.9 g, ca. 389.2 g, ca. 172.5 g, ca. 310.6 g, ca. 222.9 g, ca. 168.6 g, ca. 178 g, ca. 243.9 g, ca. 230.9 g, ca. 312 g, ca. 362.8 g, ca. 221.1 g, ca. 370 g, ca. 201.5 g, ca. 307.7 g, ca. 130.2 g, ca. 308.4 g, ca. 145.4 g, ca. 297.5 g, ca. 241 g, ca. 203.3 g, ca. 109.1 g, ca. 261.3 g, ca. 257.7 g, ca. 136.7 g, ca. 167.1 g, ca. 116.4 g, ca. 127.3 g, ca. 274 g, ca. 226.9 g, ca. 248.6 g, ca. 146.8 g, ca. 235.9 g, ca. 326.5 g, ca. 330.1 g, ca. 185.2 g, ca. 201.9 g, ca. 138.1 g, ca. 285.2 g, ca. 91 g, ca. 224.4 g, ca. 141.7 g, ca. 221.5 g, ca. 149 g, ca. 107.3 g, ca. 323.3 g, ca. 72.9 g, ca. 149.4 g, ca. 112.8 g, ca. 232.3 g

详情

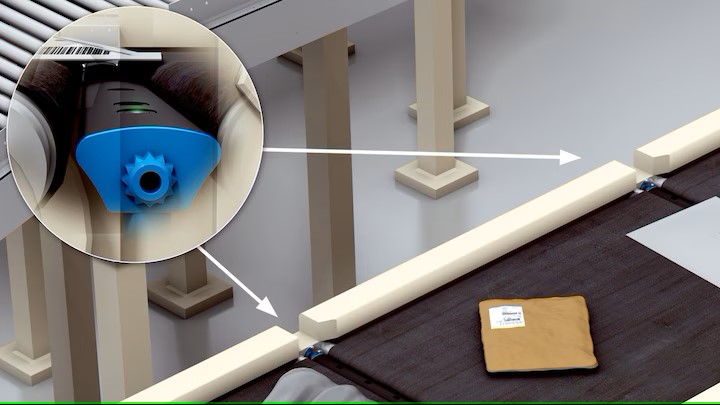

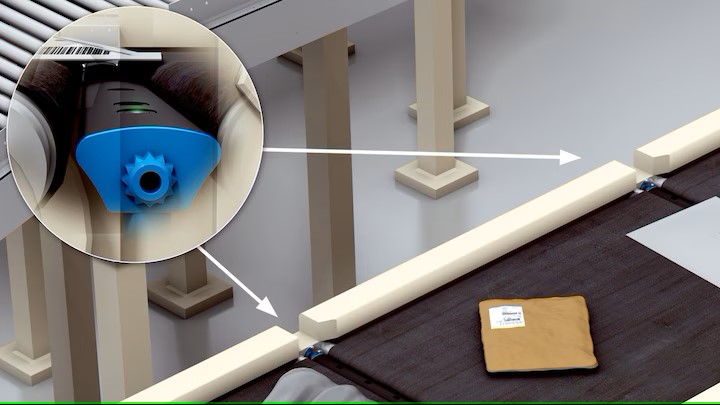

Flexible conveyor belt sensor for detecting irregular leading edges

The Roller Sensor Bar conveyor sensor is designed to be mounted between rollers and is an elegant, simple solution for reliable detection of objects with irregular leading edges. Sensing performance is optimized through the ability to configure length and beam spacing to the mm. By mounting the Roller Sensor Bar between the rollers, object catch points can be removed thereby decreasing conveyor downtime due to jams. The spring-loaded assembly of the Roller Sensor Bar, which can be mounted in the factory rather than in the field, decreases installation costs by more than half. Commissioning costs are reduced by eliminating the need to teach and align the sensor.

Roller Sensor Bar AT A GLANCE

Benefits

-Reduce conveyor downtime due to false switchings on background-objects

-Optimize sensor performance by configuring beam spacing to the mm

-Increase detection area across the entire conveyor bed by removing blind zones on the near and far side of the conveyor

-Significantly decrease installation costs with a tool-free installation using a spring-loaded end cap

-Eliminate the need for sensor alignment and teaching with factory preset sensing range

Features

-Precise detection of leading edges

-Outstanding ambient light immunity

-Easy installation

-Housing length: 200 mm to 1,200 mm (7.87" – 47.24")

-Beam separation: 50 mm to 200 mm (1.97" - 7.87")

-Number of sensing points: 2 to 8

ADVANTAGES

Easy and quick installation with spring-loaded mounting

Easy and quick installation with spring-loaded mounting

Reduce installation time by up to 30% by taking advantage of the Roller Sensor Bar’s spring-loaded end cap for seamless integration into the conveyor side channel using standard mounting brackets. Decrease installation costs by pre-mounting the sensor in the factory, thereby reducing field labor costs.

Flexible mounting options offer quick and easy integration into roller conveyors, flexible conveyors, live roller conveyers, between belted conveyor sections, and into automated storage and retrieval systems

The self-centering spring-loaded mounting mechanism ensures a quick commissioning experience by eliminating the need for installation tools and added accessories

Performance for individual applications

Performance for individual applications

Optimize the conveyor sensor’s performance by selecting a Roller Sensor Bar configuration that is designed for application requirements. The Roller Sensor Bar reduces blind zones on either end of the conveyor by offering housing lengths between 200 mm-1200 mm (7.87" – 47.24"). Configuring the length of the sensor allows for integration into many conveyor types. Performance is configured by selecting a beam spacing between 50 mm and 200 mm (1.97" - 7.87") to detect poly bags, jiffy packs, boxes, totes, and pallets. Mount the sensor between rollers or belted sections to detect objects between conveyor sections and in transfer zones.

Optimize sensor performance based on application needs: the Roller Sensor Bar accommodates between 2-8 sensing points and beam spacing between 50mm – 200 mm (1.97" - 7.87"). Remove blind zones on the near and far side of the conveyor bed by selecting a beam spacing which meets minimum detectable object requirements.

Seamless integration into conveyor control panels with 10 catalog connection types and 9 standard cable lengths

Mounting of the Roller Sensor Bar between belt sections

Precise leading edge detection and object overhang detection to decrease conveyor jams and increase efficiency

Eliminate the need to qualify multiple sensing solutions by leveraging the Roller Sensor Bar, which is configured to detect distances between 200 mm and 1200 mm (7.87" – 47.24") for a variety of conveyor widths.

Reliable sensor technology

Reliable sensor technology

Equipped with excellent ambient light immunity, the Roller Sensor Bar increases throughput by reducing false trips on objects in the background.

Reduce conveyor downtime by decreasing false detections on objects in the background using the Roller Sensor Bar’s ambient light immunity and pre-programmed sensing range

No ingress of dust, and impervious to water while cleaning due to the Roller Sensor Bar’s IP67 rated housing

更多 Truserv Technologies (M) Sdn Bhd 相关资料

Easy and quick installation with spring-loaded mounting

Easy and quick installation with spring-loaded mounting

Performance for individual applications

Performance for individual applications

Reliable sensor technology

Reliable sensor technology

Malaysia

Malaysia