AYVAZ VIBRATION ABSORBER (VIBRATION HOSE) (COPPER)

Size

Ayvaz’s VIB-FLEX anti-vibration hoses are assembled using annularly corrugated stainless steel hose and high strength stainless steel braiding and copper welding ends. They are designed for optimum performance mainly in refrigeration systems in order to absorb vibration and related damages also to prevent the noise occurs in mechanical piping of various applications.

Absorption of Vibration:

Vibration exists in mechanical systems may cause many serious problems for system manufacturers and the users. Vibration causes un-ignorable amount of material fatigue on the parts which are frequently exposed to it. Noise is also another issue to be prevented in order to provide a convenient operation for the users.

Anti-vibration hoses are used in supply lines in pumps, engines, cooling units or air conditioning equipment to reduce the transfer of vibration and noise.

Vibration absorbers are constructed with a corrugated inner hose and braided cover that helps to increase the pressure resistance rating and provides end limitations that annihilate the need for additional control assemblies.

What are the main application areas of VIB-FLEX?

Annularly corrugated metal hoses are selected according to the system pressure, temperature and the direction of the vibration and are used in the connections of the tools that cause a high level of vibration such as;

• Refrigeration Systems

• Air-conditioning units

• Heating pumps

• Pressured systems

• Pumps, motors, machines, compressors

VIB-FLEX’s copper ends are welded to flexible hose with TIG welding method. Many of other manufacturers prefer soldering method to while bringing flexible metal hose and copper ends together. This simple method seems like an economical solution to complete the assembly.

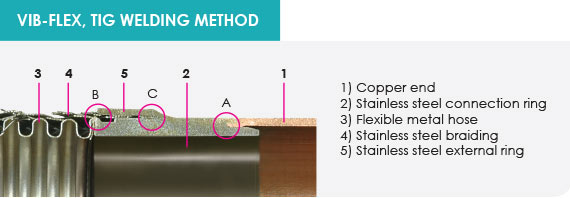

VIB-FLEX, TIG WELDING METHOD

• Triple welding action: VIB-FLEX is completed triple TIG welding action in ab argon-free environment while bringing the flexible metal hose and the copper end together.

The first welding (A) attaches the copper ending to the connection ring while the second weld (B) attaches the connection ring to the flexible hose. The third weld (C) attaches the steel braiding and the external ring to the connection ring.

• TIG Welding: TIG welding has the ability of filling up empty spaces much, minimizes the risk of pore formation and it resists against extremely high temperatures.

Safe and Easy

While anti vibration hoses with solder are installed to systems, the connection between hose and the copper ends are covered with a wet towel or cloth in order to protect the connections from over-heating which possibly damage the assembly.

Triple TIG welding process used at VIB-FLEX prevents such problems. Because it is impossible to damage TIG welding with over-heating. This safe structure also reduces the installation time and costs accordingly.

Vertical Installation

Usually, installation of anti-vibration hoses in cold places causes a frozen layer to be formed up around the hose surface. When the system is shut down, the ice starts melting and the water flows downwards to the copper end. Other manufacturers’ design allows the water to pile up in between flexible hose and external ring. When the system is restarted, the water will freeze again and its volume will increase therefore it causes the risk of explosion of the hose to inwards.

Thanks to the smart design of VIB-FLEX, there is no such space for water formation. The connection ring prevents such dangers and enable the hose assembly performs effectively.

Lebih maklumat tentang Culmi Air-Cond & Refrigeration Parts Supply Sdn Bhd

Lebih maklumat tentang Culmi Air-Cond & Refrigeration Parts Supply Sdn Bhd