Application

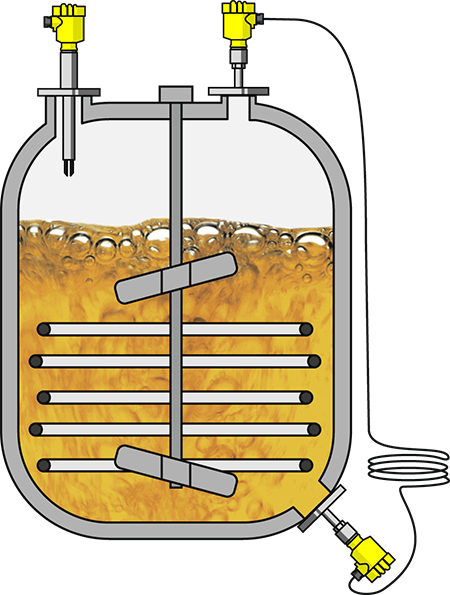

Changing media, as well as process pressures and temperatures, characterize the typical reaction processes in a reaction vessel. This is a big engineering challenge, because any sensors used to control the process need to deliver reliable measurements under these conditions. To meet the diverse conditions found in reaction vessels, level measurement and point level detection instrumentation must cover a broad spectrum of applications.

Your benefit

Reliable

Reliable measurement, independent of both ambient and process conditions

Cost effective

Highly resistant materials ensure a long service life

User friendly

Simple installation and setup

Recommended products

VEGABAR 81

Electronic differential pressure measuring system for level measurement in the reaction vessel

- Trustworthy level measurement, independent of the overpressure in the reactor

- Oil-free measuring cell makes it the ideal solution for all vacuum applications

- No influence on the measurement from internal structures, agitators or foam on the surface of the medium

- Measurement is unaffected by the ambient temperature (no external, oil-filled capillary tubes)

Measuring range - Distance

Measuring range - Pressure

VEGASWING 63

Vibrating level switch for liquids for level detection as overfill and dry run protection system in the reaction vessel

- Media-independent switching point, reliable level information

- Highly resistant materials and coatings allow use in a variety of media

- Test button for easy testing of instrument functionality during operation

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Malaysia

Malaysia