Application

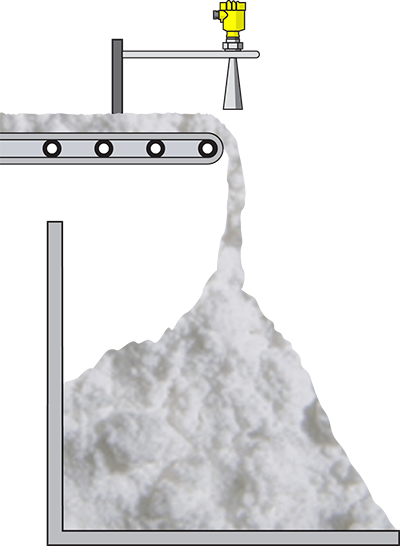

The gypsum extracted from the exhaust gases in the flue gas desulphurisation unit is transported by conveyor belts to the wet gypsum storage hall. The stockpile loading is carried out by a reversing conveyor, which is able to, when a desired filling height is reached, traverse forward or back to another discharge position. For safety reasons, there are two redundant radar sensors at the end of the reverse conveyor belt to monitor the stockpile filling height during discharge.

Your benefit

Reliable

Reliable function, even during discharge/filling

Cost effective

Simple installation onto the existing infrastructure

User friendly

Maintenance-free operation

Recommended products

VEGAPULS 68

The radar sensors monitor the filling height of the stockpile and control the movement and position of the reversing conveyor

- High plant availability with wear and maintenance-free measuring instrument

- Unaffected by condensation, dust and noise

- Approvals according to dust-Ex and SIL2

Measuring range - Distance

Malaysia

Malaysia