Application

High pressure steam is critical for the operation of the refinery. For the production and reliable supply of steam, accurate level measurement is required that allows efficient operation of the steam boiler. In addition to level measurement, high and low water limit detectors are also extremely important. As safety devices, they ensure that the water level neither exceeds the upper limit nor falls below the lower limit.

Your benefit

Reliable

High measuring accuracy independent of temperature and pressure

Cost effective

Low maintenance costs

User friendly

Simple installation

Recommended products

VEGAFLEX 86

Level measurement with guided radar in the steam drum

- Precise measurement thanks to automatic real-time correction, even under changing steam conditions

- Flexible mounting options for easy replacement of displacers or direct installation in the tank

- Meets the high safety standards of SIL2/3 according to IEC 61508 and the certification according to EN 12952-11 and EN 12953-9 for steam boilers

Measuring range - Distance

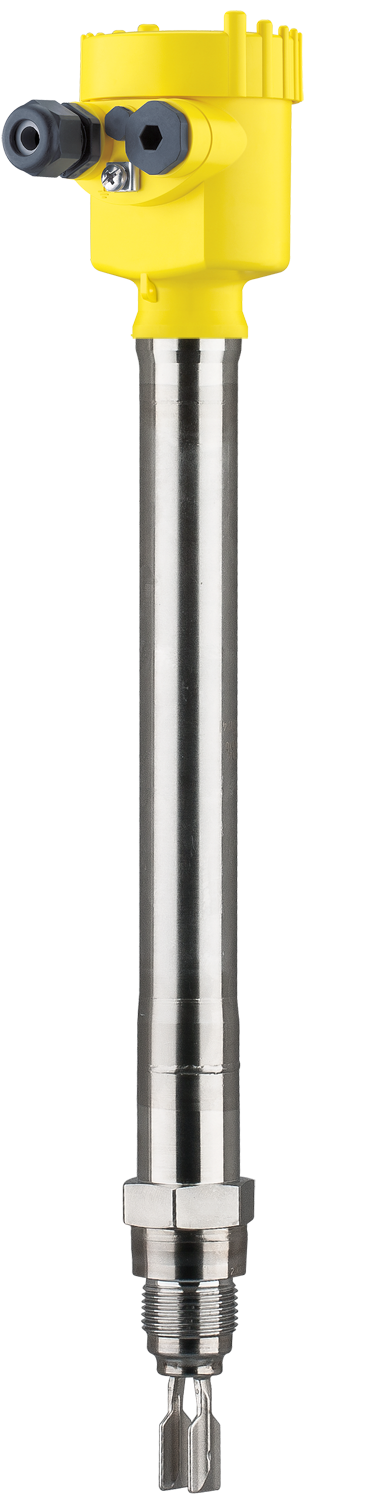

VEGASWING 66

Vibrating level switch for point level detection in the steam drum

- Simple installation without medium saves time and Money

- Precise, reliable function through product-independent switching Point

- Reliable measurement unaffected by high temperatures and pressures

- Meets the high safety standards of SIL2/3 according to IEC 61508 and the certification according to EN 12952-11 and EN 12953-9 for steam boilers

Version

Compact version

with gas-tight leadthrough

with tube extension

Malaysia

Malaysia