Preparation and measurement in a short time with the fastest drive in the class

Significantly improved drive speed reduces the time for approaching workpieces in manual mode, creating CNC programs and drive during CNC measurement. This improves efficiency throughout the inspection process, from preparation to measurement. In addition, by using a wide-range hybrid detector (for SURFCOM NEX 200 only), there is no need to measure surface texture and contour shape separately, and necessary precise alignment before measuring the surface texture of inclined or curved surfaces can be skipped. This means inspections can be performed with minimal effort in the shortest period of time.

The world’s only linear motor drive machine that can measure ultra-low vibration and operate at 20±5 degrees Celsius.

SURFCOM NEX inherits the linear motor drive unit, a patented technology of ACCRETECH, from a conventional SURFCOM NEX. An ultra-low vibration drive mechanism reduces noise caused by vibration and provides high-accuracy measurement results. Moreover, by offsetting the impact of temperature change on the scale in real time, accuracy can be assured over a wide temperature range of 20±5 degrees Celsius. Reliable measurement results are obtainable even in environments where temperature control is difficult.

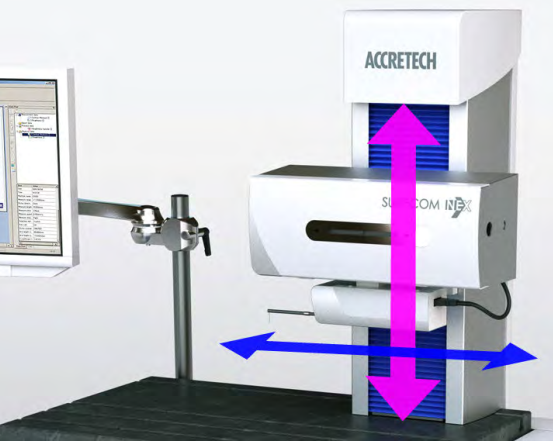

X-axis (horizontal): 100 mm/s, 1.6 times faster than conventional instruments

C-axis (vertical): 50 mm/s, 5 times faster than conventional instruments (Patented)

.png)

The linear motor tracing driver minimizing vibration and achieving highly accurate measurement. (Patented)

| Item/Model | SURFCOM NEX 030/040 DX2/SD2 | |||||||||||

| 12 | 13 | 14 | 15 | 22 | 23 | 24 | 25 | |||||

| Tracing driver | X-axis (L: measuring length mm) |

Sensing Method | Linear Scale | |||||||||

| Straightness Accuracy | with High-accuracy contour detector (µm/mm) | 0.08/100 | 2.0/200 | |||||||||

| with General-purpose contour detector (µm/mm) | 0.08/100 | 2.0/200 | ||||||||||

| X-axis indication accuracy (µm): horizontal*¹ | ±(0.8+1.0L/100) (L: Measuring length mm) *Contour measurement with 100 mm driver |

|||||||||||

| ±(0.8+3.0L/200) (L: Measuring length mm) *Contour measurement with 200 mm driver |

||||||||||||

| Resolution (µm) | 0.016 | |||||||||||

| Speed (mm/s) | Travel Speed | 0.03 to 100 | ||||||||||

| Measuring Speed | 0.03 to 30 | |||||||||||

| Tilt Angle* | ±15 (Optional tilting device) | |||||||||||

| Measuring Stand | Column | Speed (mm/s) | Travel Speed | CNC | Max. 50 | |||||||

| Joystick | Max. 35 | |||||||||||

| Base | Material | Gabbro | ||||||||||

| Model/Item | SURFCOM NEX 030 DX2/SD2 | ||||||||||

| 11 | 12 | 13 | 14 | 22 | 23 | 24 | 25 | ||||

| General-Purpose Contour Detector | Measuring Range | Z-axis (mm): Vertical | 60 | ||||||||

| Contour | Sensing method | High accurary scale | |||||||||

| Resolution (µm) | 0.04 (Full range) | ||||||||||

| Indication accuracy (µm): vertical | ± (1.2+|2H|/100) (H: Measuring height mm) *at 20 ±2°C | ||||||||||

| ± (1.5+|2H|/100) (H: Measuring height mm) *at 20 ±5°C | |||||||||||

| Stylus | for Contour | Model | DM45505 (Standard accessory for NEX 3**) | ||||||||

| Measuring Force (mN) | 10 to 30 (Manually Adjustable) | ||||||||||

| Tip Material | Cemented Carbide | ||||||||||

| Tip Shape | Rtip 25 µm/24° cone | ||||||||||

| Function | Downward measurement / Collision detection safety function / Retract function | ||||||||||

| Model/Item | SURFCOM NEX 040 DX2/SD2 | ||||||||||

| 11 | 12 | 13 | 14 | 22 | 23 | 24 | 25 | ||||

| High-Accuracy Contour Detector | Measuring Range | Z-axis (mm): Vertical | 60 | ||||||||

| Contour | Sensing method | Laser optical diffraction scale | |||||||||

| Resolution (µm) | 0.02 (Full range) | ||||||||||

| Indication accuracy (µm): vertical | ± (0.8+|2H|/100) (H: Measuring height mm) | ||||||||||

| Stylus | for Contour | Model | DM45505 (Standard accessory for NEX *4*) | ||||||||

| Measuring Force (mN) | 2 to 30 (Adjustable on measuring/analysis integrated software “ACCTee”) | ||||||||||

| Tip Material | Cemented Carbide | ||||||||||

| Tip Shape | Rtip 25 µm/24° cone | ||||||||||

| Function | Down/upward measurement / Collision detection safety function / Retract function | ||||||||||

| Power Supply | Voltage (V) , Frequency (Hz) | Single phase AC100 to 240, 50/60 | |

| Power Consumption (VA) | Max. 930 | ||

| Air Supply | Supply pressure (MPa) | 0.45 to 0.7 | |

| Working pressure (MPa) | 0.4 | ||

| Air consumption (L/min) | 0.1 (Max. 10) | ||

| Position of supply port | DX2 model: main body lower left / SD2 model: main body back side (with anti-vibration table) |

||

| Air supply connecting port | One-touch pipe joint for tubes with Outside diameter Ø6 mm | ||

| Environment | Temperature | Temperature of accuracy guarantee (°C)*2*3 | 20±5 (Ratio of temperature change ±0.5 / within an hour 0.1 / within one measuring time) |

| Temperature of operation guarantee (°C) | 15 to 30 | ||

| Storage temperature (°C) | 5 to 40 | ||

| Humidity | Humidity of operation guarantee (%) | 4o to 80 (without condensation) | |

| Storage humidity (%) | 80 (without ceondensation) | ||

*1 Excluding when using roughness pickup

*2 Guaranteed accuracy is excluding deformation of workpiece,caused by temperature change.

*3 Indication accuracy(vertical) with general-purpose contour detector is variable depending on temperature range.

Malaysia

Malaysia