Flexible, smart, compact: Encoders for countless fields of application

AHS/AHM36 absolute encoders set standards when it comes to mechanical adaptation, communication and resistance to environmental influences. With their rotatable male connector or cable connection as well as various mounting hole patterns and adapter flanges, these encoders are suitable for nearly any application. The IO-Link, CANopen, SAE J1939 and SSI interfaces enable easy integration into various control environments. Encoder configuration can be adapted to individual needs using various tools. The rugged, reliable, fully magnetic sensor system provides a maximum resolution of 14 bits (singleturn) or 26 bits (multiturn). Due to the stainless steel design and enclosure rating IP69K, the Inox versions are suitable for use under very harsh ambient conditions.

AHS/AHM36 AT A GLANCE

Benefits

-Simple mechanical installation thanks to the rotatable male connector or cable connection and various mounting hole patterns and shafts

-Easy integration into various control environments with IO-Link, CANopen, SAE J1939 and SSI interfaces

-Intelligent diagnostic functions evaluate maintenance intervals for the entire system

-Thanks to the rugged, reliable, fully magnetic sensors, they can also be used in harsh environments

-High resistance to ambient influences due to stainless steel design and IP69K enclosure rating (Inox versions)

-Space-saving and cost-effective design

-High performance at a cost-efficient price

Features

-36 mm absolute encoder with max. 26 bits (singleturn: 14 bits, multiturn: 12 bits)

-Face mount/servo flange, blind hollow shaft

-Rotatable male connector or cable connection

-IO-Link, CANopen, SAE J1939, SSI interface with programmable parameterization

-Diagnostic functions

-Stainless steel (Inox versions)

-Enclosure rating up to IP67 or IP69K

ADVANTAGES

For encoders, flexibility is key

For encoders, flexibility is key

In order to provide maximum flexibility in the design of the mechanical interface, the AHS/AHM36 encoders are available with three different flange types (face mount flange, servo flange, blind hollow shaft), each with five different shaft diameters. Various assembly hole patterns are available in the face mount flange. A range of different pitch hole diameters are covered by the flexible stator coupling on the blind hollow shaft. And last but not least, a range of adapters guarantees compatibility with almost all absolute encoders with typical 60 mm flange designs. With the rotatable male connector or cable connection, the AHS/AHM36 can be integrated into the application in even the most limited of spaces and reduces the number of encoder variants when different installation situations are required.

Quick replacement for permanent benefit

Various assembly hole patterns in the face mount flange

AHS/AHM36 with M12 male connector, rotated in axial direction

With the rotatable male connector or cable connection, the AHS/AHM36 can be integrated into the application in even the most limited of spaces and reduces the number of encoder variants when different installation situations are required

Due to their compact size, the various flange types, adapter flanges and assembly hole patterns as well as the rotatable male connector or cable connection, the AHS/AHM36 devices can be integrated into virtually any application

Encoders for rough environments

Encoders for rough environments

The solution for applications with particularly harsh ambient conditions is AHS/AHM36 stainless steel Inox encoders. The housing, flange, shaft and stator coupling are made entirely of stainless steel (1.4305). Enclosure rating IP69K ensures additional impact protection which protects the shaft sealing ring installed in the encoder from the water jet of the shock blower.

AHS/AHM36 Inox with blind hollow shaft and cable connection

AHS/AHM36 Inox with face mount flange and M12 male connector

AHS/AHM36 Inox devices offer high resistance to environmental influences. With the IP69K enclosure rating, the encoders are suitable for use in machines that are regularly cleaned with high-pressure cleaners.

Advantages with IO-Link

Advantages with IO-Link

IO-Link is a point-to-point communication protocol for connecting intelligent sensors and actuators within an automation network. SOPAS ET – the configuration software from SICK – allows IO-Link devices such as the AHS/AHM36 IO-Link to be easily visualized and parameterized. AHS/AHM36 IO-Link can be connected to any IO-Link master. The IO-Link offers a lot of benefits, e.g. automated storage of device parameters, unique device identification and the use of cost-efficient unshielded standard cables. In the Advanced and Inox versions, the AHS/AHM36 encoders offer extensive IO-Link functions, such as providing and storing diagnostic data (temperature, operating time, etc.), a configurable input and output pin, and integrated Smart Tasks, e.g. for length measurement. Thanks to their remote intelligence, these encoders provide the prerequisites for successful integration in more extensive edge computing concepts used for applications in Industry 4.0 and Smart Factory implementation.

The AHS/AHM36 IO-Link Advanced and AHS/AHM36 IO-Link Inox encoders provide countless diagnostic data such as temperature values and operating hour counters

Thanks to remote intelligence, the AHS/AHM36 IO-Link can be successfully integrated into more comprehensive edge computing concepts when implementing Industry 4.0 and the Smart Factory

The IO-Link interface enables cost-effective and easy integration of AHS/AHM36 devices into Ethernet and fieldbus networks. The provision and saving of diagnostic data, a configurable input and output pin and integrated Smart Tasks offer the user countless additional benefits.

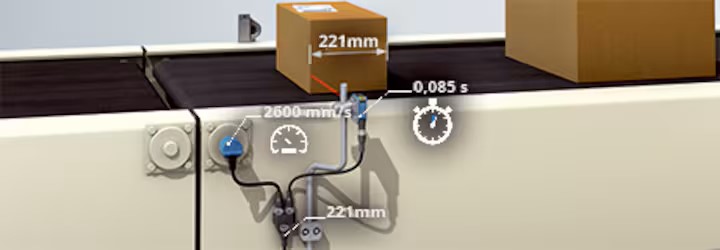

Measurement of object lengths and gaps between objects

The AHS/AHM36 IO-Link Advanced absolute encoder is suitable for measuring belt speeds. Thanks to the integrated A30 Smart Task, it can be combined with a photoelectric retro-reflective sensor to also detect the lengths of objects and the gaps between objects. Limit values can be defined for the latter, which the encoder monitors.

The Smart Task application enables the encoder to make decisions remotely and execute them autonomously. The encoder therefore takes care of functions at the superordinate automation level, thereby improving response times because it reduces the communication load over the Ethernet and fieldbus networks.

In addition, the AHS/AHM36 offers extensive IO-Link functionalities, such as providing and storing diagnostic data (temperature, operating time, etc.) as well as a configurable input and output pin. The encoder provides valuable information, e.g. for process optimization and condition monitoring.

Length measurement of packaging film

The AHS/AHM36 IO-Link Advanced absolute encoder, in combination with a print mark sensor, measures the exact length of packaging film. With the help of the integrated A30 Smart Task, after a set length value passes through, a trigger signal can be output with which the downstream cutting system is controlled for singulation of packaging films. Direct length measurement in the encoder also works precisely and reliably when conveying speeds change.

The Smart Task application enables the encoder to make decisions remotely and execute them autonomously. The encoder therefore takes care of functions at the superordinate automation level, thereby improving response times because it reduces the communication load over the Ethernet and fieldbus networks.

In addition, the AHS/AHM36 offers extensive IO-Link functionalities, such as providing and storing diagnostic data (temperature, operating time, etc.) as well as a configurable input and output pin. The encoder provides valuable information, e.g. for process optimization and condition monitoring.

Advantages of CANopen, SAE J1939 and SSI

Advantages of CANopen, SAE J1939 and SSI

The three communication interfaces CANopen, SAE J1939 and SSI, with which the AHS/AHM36 encoders are available, also offer many advantages.

The position, speed and current temperature process data is output via the CANopen and SAE J1939 interfaces. AHS/AHM36 CANopen additionally communicates diagnostic data, such as maximum speed, minimum and maximum temperature as well as operating time. AHS/AHM36 CANopen and AHS/AHM36 SAE J1939 can be configured either via the engineering tool of the respective controller, or via the PGT-12-Pro hand-held programming tool from SICK.

The programmable AHS/AHM36 SSI devices can be used both via the SICK SOPAS engineering tool or via the PGT-10-Pro hand-held programming tool. Various parameters such as the resolution, counting direction and code type can be customized according to the application. Even the structure of the SSI protocol to be output can be adapted so that the AHS/AHM36 encoders are compatible with virtually any SSI encoder.

In addition to the position and speed, AHS/AHM36 CANopen and AHS/AHM36 SAE J1939 can also output the current operating temperature of the encoder as process data. AHS/AHM36 CANopen can also communicate additional diagnostic data

AHS/AHM36 CANopen, AHS/AHM36 SAE J1939 and AHS/AHM36 SSI can be parameterized easily and comprehensively via a hand-held programming tool

AHS/AHM36 SSI encoders can also be parameterized using the PC-based SICK SOPAS engineering tool

AHS/AHM36 CANopen, AHS/AHM36 SAE J1939 and AHS/AHM36 SSI can be parameterized individually, making it possible to adjust them flexibly to nearly any application. Thanks to the compact, hand-held programming tools, this is done independently and without the installation of hard- or software.