Option:

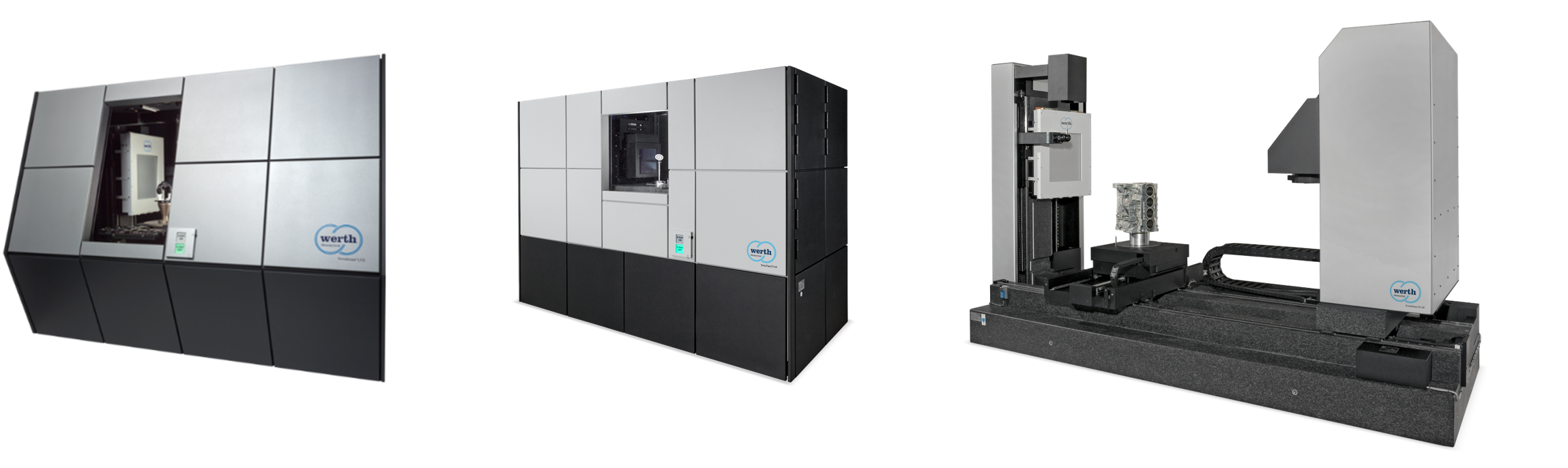

Ever since Werth presented the first X-ray tomography machine developed especially for coordinate measuring technology, with optional multisensor systems, the machines in the Werth TomoScope® series have enabled the complete, precise, and non-destructive measurement of workpieces. This technology minimizes first article inspection times for rapid product validation, thus reducing development costs. Special measurement methods also make it possible to monitor processes with high throughput due to short measurement times.

X-ray images of the workpiece are taken at various rotated positions. With suitable mathematical methods, they can be used to calculate a complete, high-resolution volumetric model. A patented subvoxeling process determines the measurement points at the material boundaries.

The 3D point cloud can be compared directly with the 3D CAD model, imported for example in IGES or STEP format. Each point is automatically associated with the corresponding patch in the CAD model. WinWerth® measuring software generates a color-coded deviation plot for each measurement point in comparison with the specified CAD surface.

The points associated with a geometrical feature are selected for analysis, either using automatic segmentation or simply by clicking on the CAD model (patent). WinWerth® calculates the corresponding standard geometrical features (line, cylinder, plane, etc.) and links them into dimensions, generating a measurement report on request. Using virtual planes, measurements can be performed in any cross section of the volume or point cloud (patent pending). Workpieces made of several different materials can be measured using this technique.

The design principle of the CT machines, based on proven components from Werth coordinate measuring machines, ensures stability and precision. All TomoScope® and TomoCheck® machines meet the requirements to be considered cabinet X-ray systems.

The CT measurements can be traced back to the internationally recognized length standard of the German National Metrology Institute (PTB – Physikalisch-Technische Bundesanstalt), using calibrated standards in accordance with VDI 2617 or VDI 2630, with a DAkkS calibration certificate available on request. CT measurements, e.g., on plastics, can be performed with measurement errors of a few micrometers. If precision in the sub-micron range is required for workpieces that are difficult to penetrate radiographically, multisensor systems can help reduce systematic measurement errors due to artifacts, using patented Werth Autocorrection.

Special measurement methods, such as OnTheFly CT, Eccentric CT (patent), Multi-ROI CT, Raster Tomography, and Dual-Spectra CT are available to increase the measuring speed or resolution, to expand the measurement range, and to measure workpieces made of multiple materials.

The measurement time for first article inspection of a workpiece has been reduced from several days, using classical measurement techniques, to a few minutes with CT. Product development can thereby be sped up significantly, which increases cost-effectiveness. With extensive and precise information about the workpiece, mold corrections can be implemented in a fraction of the time.

The operation of machines with a wide variety of sensors, but also the evaluation of volume data and point clouds are possible with WinWerth® in a unique combination. The Werth image processing software is based on 40 years of experience and is the foundation of probably the most powerful image processing sensors for coordinate measuring machines currently available. Optical distance sensors, conventional styluses in single-point or scanning mode, the Werth Fiber Probe®, X-ray computed tomography or machines with a combination of several sensors are all supported by the uniform concept. Measurement points, 2D images or volume data can also be conveniently evaluated in terms of geometrical characteristics or with part-to-part deviation analysis. PTB-certified evaluation algorithms ensure correct measurement results. All desired information is displayed in the graphic: CAD models with PMI data, voxel volumes, measurement point clouds, colour-coded deviation plots from 3D nominal-actual comparisons, video images, measurement and calculation elements as well as flags with nominal and actual values, tolerances and deviations. In order to meet the most diverse requirements, the software has a modular structure. Various machines can be operated, from simple measuring projectors to complex multi-axis coordinate measuring machines with multi-sensor systems or even X-ray tomography sensors.

The “intelligence” of the WinWerth® measurement software then takes over, for example, the exact determination of the object area to be captured, the selection of the geometrical element to be measured (e.g. e.g. straight line, circle, corner point) as well as the linking algorithms for determining geometrical characteristics such as distances, angles and diameters.

Measurement points or scan lines are automatically distributed on the geometry elements to be measured, e.g. as circles, cylinder surface lines, stars or spirals, taking into account the necessary travel paths. In this way, the complete measurement sequence, including evaluation, is first created offline using the CAD model or online with the minimum number of points for the respective geometry element.

The evaluation is mainly realised by PC hardware and software. In a first processing step, the image can be improved with image filters (optimising contrast, smoothing surface disturbances). This enables reliable measurements even with difficult edges and rigid scanning in incident light.

The feature tree in the WinWerth® user interface also controls the test and change mode, in which programmes can be run step-by-step and changes can be added. A text editor, available in parallel, allows experienced operators to directly enter or change DMIS programme code while teaching in programmes.

Measurement programs can be generated both online and offline using 2D or 3D CAD models. The CAD models are imported in either STEP, native CAD or IGES format. In offline mode a sensor is selected and a patch or combination of several patches is selected on the CAD model. The software computes the necessary actions for the sensor and automatically generates the corresponding segment of the program. The graphic shows the simulated measurement sequence. In online mode the procedure is similar to the offline mode, but the coordinate measuring machine immediately performs each operational step so it can be observed “live.

With 2D contour image processing and the associated image processing filters, measurements can also be taken in any cross section of the CT volume or point cloud. Among other things, this makes the measurement of workpieces made of several materials particularly easy.

With the help of section tomography or ROI tomography (ROI: Region of Interest), parts of the measuring object are measured with high resolution without having to capture the entire measuring object, e.g. , completely with high resolution using Raster Tomography, which is time-consuming and requires a lot of memory. Multi-ROI tomography offers a combination of the benefits of eccentric and sectional tomography scans. Multiple parts with high resolution can also be selected at any position in the measuring object.

A special feature of Werth is the automatic detection and measurement of burrs or chips during the measurement sequence. The result is a colour-coded deviation plot of the burr and the maximum burr length. The deviation display optionally shows only those points where the burr length exceeds the tolerance limits. The burr length along the entire burr can also be displayed numerically via analysis markers. For example, every 0.5 mm a flag is set that contains the maximum local burr length.

WinWerth® displays all the measured elements along with the selected geometrical characteristics in the 2D or 3D graphics window. The report generator summarizes the various outputs in “Office style.

| Model | TomoScope® L | |

| General | ||

| Machine Type | Multisensor coordinate measuring machine with CT device | |

| Probing System | Compact X-ray sensor, Optical Sensors, Image Processing, Mechanical Probing Systems: Trigger and Scanning Probes | |

| Modes of Operation | Linear path control | |

| Measuring Software | WinWerth® | |

| Operating System | MS Windows | |

| Measuring Range | ||

| Max. part dimensions for tomography*** | For “In the image“ measurements from L = 175 mm, Ø = 175 mm to L = 379 mm, Ø = 340 mm |

Option raster tomography from L = 493 mm, Ø = 299 mm to L = 678 mm, Ø = 470 mm |

| Max. part dimensions for other Sensors | L = 600 mm (23.6″) One-sided: Ø = 500 mm (19.7″) |

|

| Max. distance X-ray source – detector: | FDD = 1250 mm (49.2″) | |

| Dimensions and Masses [Installation area (without instrument table)]: | ||

| Depth | 1980 mm (78″) | |

| Width | 2570 mm (101.2″) | |

| Height | 1976 mm (77.8″) | |

| Machine Weight | 8000 kg – 11000 kg (17640 Ibs. – 19845 Ibs.) | |

| Workpiece Weight mmax | 40 kg (88 Ibs.); Optional 75 kg (165 Ibs.) | |

| – For specified Error MPE | 10 kg (22 Ibs.) | |

| X-Ray Components | ||

| X-Ray Source (according to requirement) | Transmission target: 130 kV, 160 kV, 190 kV, 225 kV, 240 kV, 300 kV Reflection target: 225 kV, 270 kV, 300 kV |

|

| Detector: | ||

| – Surface Area | from 200 mm x 200 mm² to 432 mm x 432 mm² | |

| – Number of Pixels | from (1000 x 1000) pixel to (4000 x 4000) pixel | |

| – Pixel Center Distance | 100 µm to 200 µm | |

| Additional Performance Data | ||

| Resolution of Linear Measuring System | 0.1 µm (0.000004″) | |

| Positioning Speed vmax | 150mm/s | |

| Accelearation amax | 300mm/s² | |

| Supply Data** | ||

| Voltage | 430 V (230 V) ±10% | |

| Frequency | 48 – 62 Hz | |

| Power Consumption | Max. 2000VA | |

| Air Pressure | 5.5 – 10 bar | |

| Air Consumption | 3000 Nl/h | |

| Permissible Environmental Conditions | ||

| Environmental Air | Humidity 40% – 70% rel. hum., oil free | |

| Air Contamination | Max. 0.05 mg/m³ | |

| Operating Temperature | 10 – 35 °C (50 – 95 °F) | |

| Maximum Permissible Error MPE (Extract) | |||

| For advanced laboratory conditions | |||

| Optical and Tactile Sensor 1) 2) | E1: (2.5 + L/120) µm | E2: (2.9 + L/100) µm | E: (4.5 + L/75) µm |

| CT Sensor 2) | P: 4.5 µm | E: (4.5 + L/75) µm | SD: (3.5 + L/100) µm |

| No air-conditioning required | |||

| Optical and Tactile Sensor 1) 3) | E1: (4.5 + L/120) µm | E2: (6 + L/75) µm | E: (7.5 + L/50) µm |

| CT Sensor 3) | P: 7.5 µm | E: (7.5 + L/50) µm | |

1) Measured with TP200 or sensor with equal or better probing error

2) ∂ = 20 °C ± 2 K ∇∂ = 1 K/h m ≤ 2 kg (4.4 Ibs.)

3) ∂ = 16 °C to 30 °C ∇∂ = 2 K/h, 2 K m ≤ 2 kg (4.4 Ibs.)

| Description | Number of Pixels | Pixel Size | Max. part Dimensions for “in the image” Measurements (mm) | Max. part Dimensions with Raster Tomography (mm) |

| X-DETECTOR PE1000 | 1000 x 1000 | 200 µm | Ø = 175 mm / L = 175 mm | Ø = 299 mm / L = 493 mm |

| X-DETECTOR PE2000 | 2000 x 2000 | 200 µm | Ø = 319 mm / L = 351 mm | Ø = 451 mm / L = 652 mm |

| X-DETECTOR PE2000/15 | 2000 x 2000 | 200 µm | Ø = 319 mm / L = 351 mm | Ø = 451 mm / L = 652 mm |

| X-DETECTOR PE3000 | 2880 x 2880 | 150 µm | Ø = 340 mm / L = 379 mm | Ø = 470 mm / L = 678 mm |

| X-DETECTOR PE4000 | 4000 x 4000 | 100 µm | Ø = 319 mm / L = 351 mm | Ø = 451 mm / L = 652 mm |

| X-DETECTOR VA2000H | 1874 x 1496 | 127 µm | Ø = 206 mm / L = 169 mm | Ø = 345 mm / L = 486 mm |

| X-DETECTOR VA2000V | 1496 x 1874 | 127 µm | Ø = 166 mm / L = 209 mm | Ø = 284 mm / L = 524 mm |

| X-DETECTOR VA2000/4H | 2176 x 1792 | 139 µm | Ø = 253 mm / L = 218 mm | Ø = 391 mm / L = 532 mm |

| X-DETECTOR VA2000/4V | 1792 x 2176 | 139 µm | Ø = 214 mm / L = 265 mm | Ø = 354 mm / L = 574 mm |

Malaysia

Malaysia