Specifications

- Control Mode: Full Digital Control

- Rated Input Voltage: AC 3PH 380V+-25%

- Rated Input Power: 12.9Kva/ 11.4kw

- Power Factor: 0.94

- Efficiency (%): 88%@315A

- Inverter Switching Frequency: 110 Khz

- Rated Output Current: 315A

- Rated Output Voltage: 22.6V

- Input Frequency: 40 ~ 70 Hz

- Duty Cycle (%): 100%@315A

- Insulation Grade: H

- Parameter: 50

- Ingress Protection: IP23s

- Set Current Range: DC TIG 3-315A, AC-TIG 4-315A, MMA 30-315A

- DC Pulse Frequency: 0.1 - 3000Hz

- AC Pulse Frequency: 20 - 300Hz

- Pulse Width: 1 - 99%

- Arc Striking Method: High frequency arc / Lifting arc

- Rise Time: 0 - 20s Continuous regulation (0.1 increment)

- Fall Time: 0 - 20s Continuous regulation (0.1 increment)

- Pre-gas Time: 0 - 25s Continuous regulation (0.1 increment)

- Post-gas Time: 0 - 25s Continuous regulation (0.1 increment)

- Cooling Method: Forced-Air

- Material: Carbon Steel, Stainless Steel, Aluminum Alloy, Copper

- Gross Weight: 40 kg

- Dimension (mm): 647 x 291 x 572

- Application: Automotive & Railway, Construction & Mining Machinery, Ship-Building & Marine Engineering, Heavy Steel Construction, Shipping Container

- Extension Function: IOT SMARC System (Optional), USB Upgrade, Robot(Optional), LCD Front Panner (Optional)

- Warranty: 2 Years

Penerangan

- Comprehensive applications: carbon steel, 9Ni, stainless steel, alloy steel, copper, magnesium alloy, aluminum, AL alloy and others, adaptive for dissimilar-metal welding

- Extensive functions with AC-DC TIG, AC-DC Pulse TIG, high speed TIG spot welding and MMA

- Full digital intelligent control is adopted. Internal background menu is open and adjustable to better satisfy more technological requirements of various working conditions

- VRD anti-shock function with adjustable arc force in MMA mode and better arc stiffness

- IOT interface is reserved to quickly access to Megmeet SMARC management platform or the third party welding data management system to realize efficient welding interconnection

- Communication interface is reserved to support multiple types of communication protocols to connect with various brands of robots and automation devices

- Software is up-gradable through U-disk interface to help customers easily obtain Megmeet foremost welding process or customized functions

- Optional foot switch, water cooler, water-cooled torch, trolley, etc

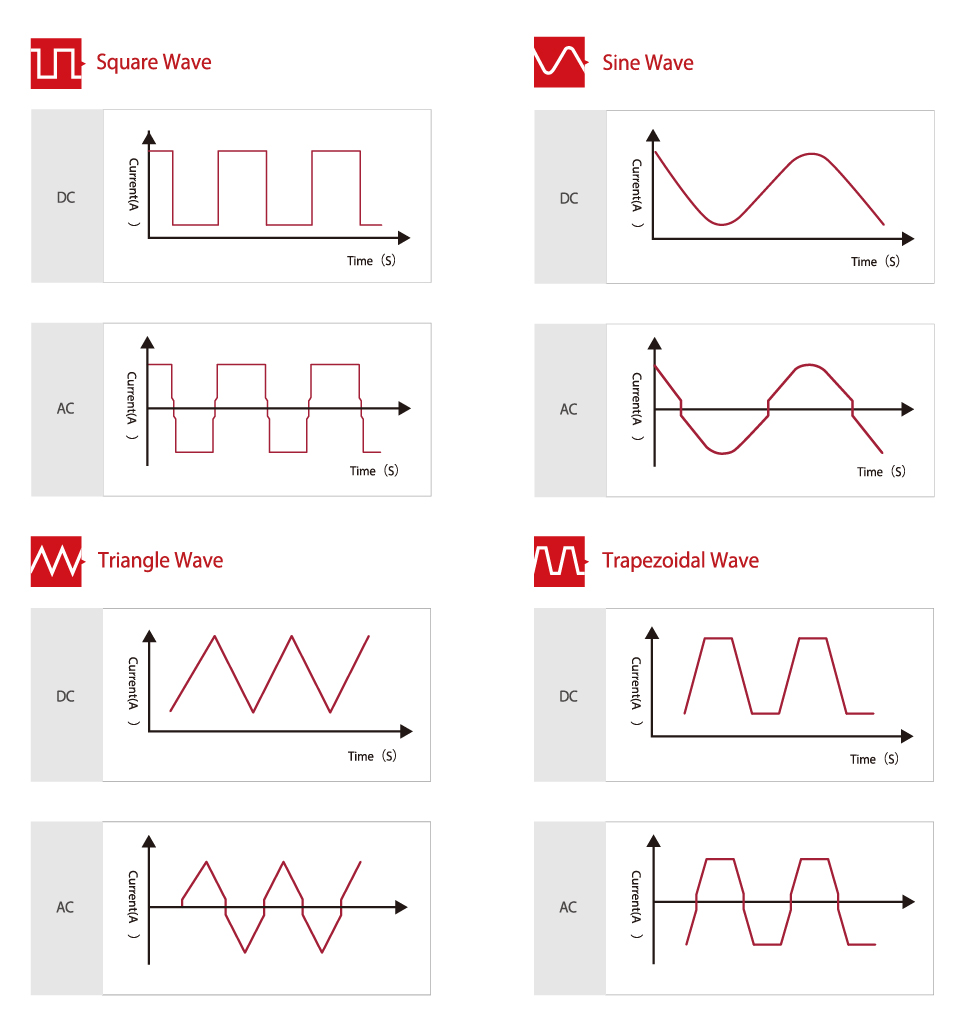

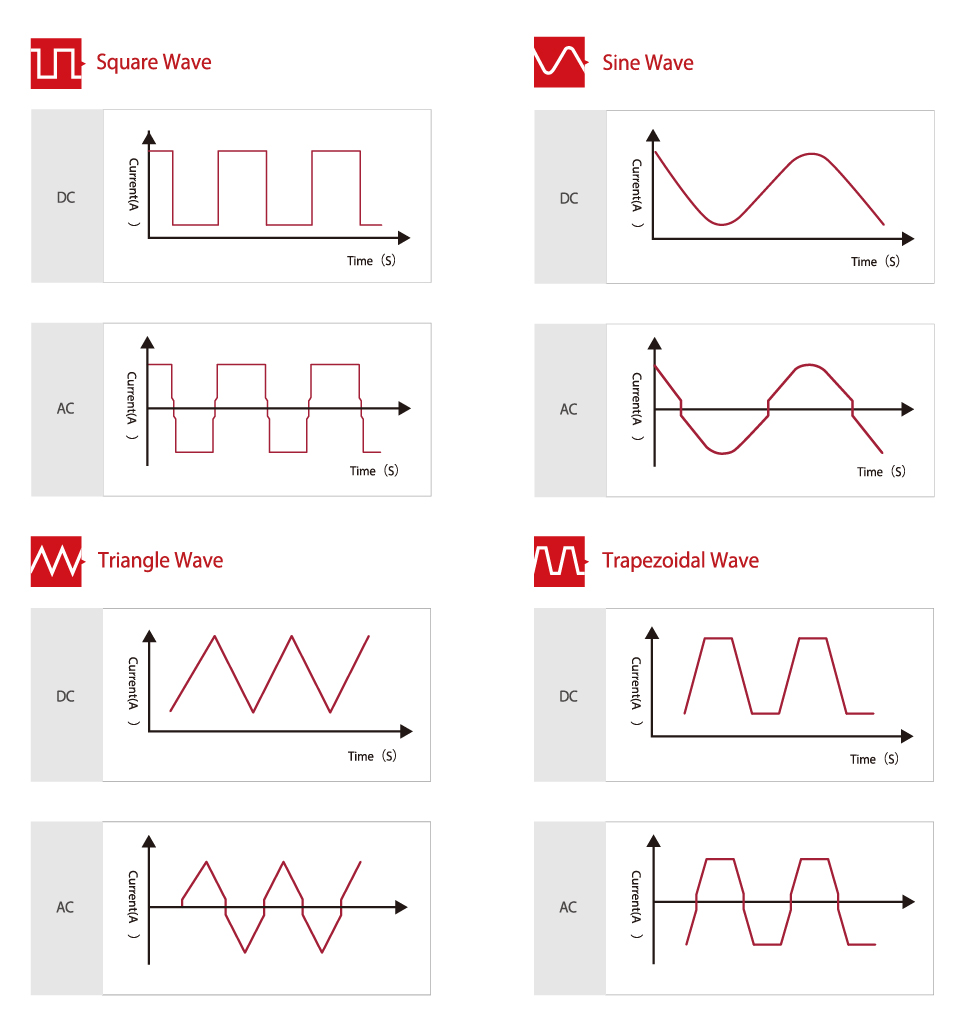

Multiple Waveform controls provide optimal combinatio according to welding needs

- Square Wave - DC/AC square wave, polarity fast-switching, high- stability of arc, good dynamic characteristics, strong ability to clean aluminium oxide film, suitable for a wide range of aluminium and aluminium alloy welding.

- Trapezoidal Wave - DC/AC trapezoidal wave, polarity stable-switching, soft arc brings good wetting effect to fusion pool, applicable for groove welding and overhead welding

- Triangle Wave - Short peak-time and low heat-input, suited to welding of thermo-sensitive metals as thin plate

- Sine Wave - DC/AC sine wave, rectangular transition at zero-crossing point, less and softer arc nosie

Picture are for illustration purpose only, actual may vary. Specifications are subject to change without prior notice.

Lebih maklumat tentang LEEDEN HERCULES SDN BHD

Malaysia

Malaysia