Specifications

- Control Mode: Full Digital Control

- Rated Input Voltage: AC 3PH 380V卤25%

- Rated Input Power: 12.5Kva/ 11.4kw

- Power Factor: 0.94

- Efficiency (%): 91%@315A

- Inverter Switching Frequency: 110 Khz

- Rated Output Current: 315A

- Rated Output Voltage: 22.6V

- Input Frequency: 45 ~ 70 Hz

- Duty Cycle (%): 100%@315A

- Insulation Grade: H

- Parameter: 50

- Ingress Protection: IP23

- Set Current Range: DC TIG 3-315A, MMA 30-315A

- DC Pulse Frequency: 0.1 3000Hz

- Pulse Width: 1 - 99%

- Arc Striking Method: High frequency arc / Lifting arc

- Rise Time: 0 - 20s Continuous regulation (0.1 increment)

- Fall Time: 0 - 20s Continuous regulation (0.1 increment)

- Pre-gas Time: 0 - 25s Continuous regulation (0.1 increment)

- Post-gas Time: 0 - 25s Continuous regulation (0.1 increment)

- Cooling Method: Forced-Air

- Material: Carbon Steel, Stainless Steel, Titanium Alloy, etc

- Gross Weight: 37 kg

- Dimension (mm): 647 x 291 x 572

- Application: Automotive & Railway, Construction & Mining Machinery, Ship-Building & Marine Engineering, Heavy Steel Construction, Shipping Container

- Extension Function: IOT SMARC System (Optional), USB Upgrade, Robot(Optional), LCD Front Panner (Optional)

- Warranty: 2 Years

Penerangan

- Wide applications: supporting carbon steel, stainless steel, alloy steel and other metal materials

- Comprehensive functions with pulse DC TIG, high speed TIG spot welding, MMA and others

- Full digital intelligent control is adopted. Internal background menu is open and adjustable to better satisfy more technological requirements of various working conditions

- VRD anti-shock function with adjustable arc force an better arc stiffness in MMA mode

- IOT interface is reserved to quickly access to Megmeet SMARC management platform or the third party welding data system to realize efficient welding interconnection

- Communication interface is reserved to support multiple types of communication protocols to connect with different brands of robots and automation devices

- Software is upgradable through U-Disk interface to help customers easily obtain Megmeet foremost welding process or customized functions

- Optional foot switch, water-cooler, water-cooled torch, trolley, etc.

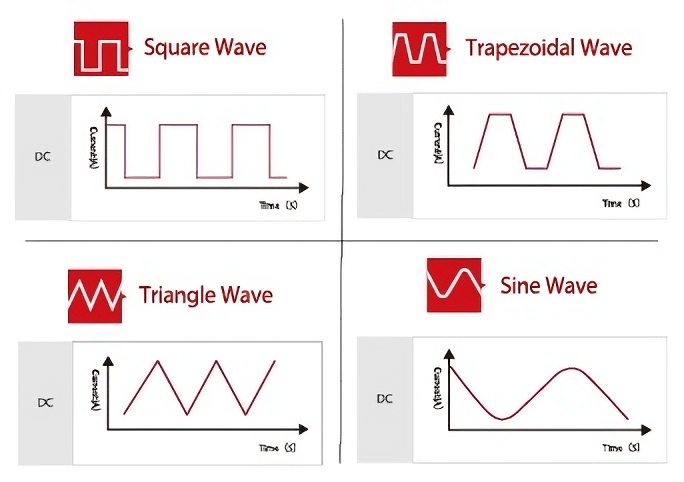

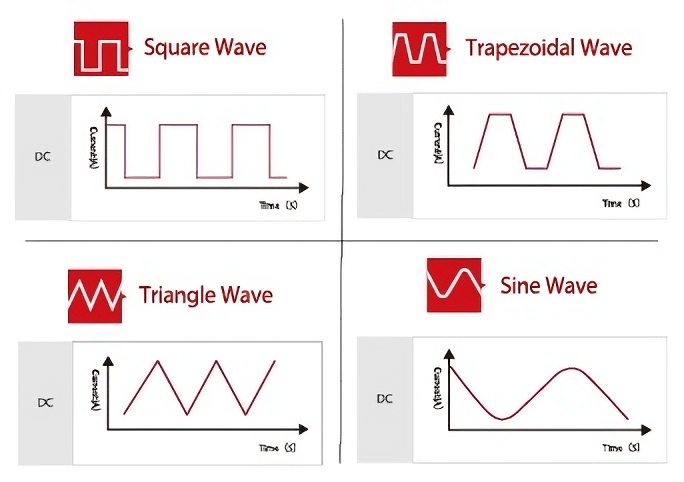

Multiple Waveform controls provide optimal combinatio according to welding needs

- Square Wave - Precision control in current waveform and accurate adjustment in parameters of peak current, frequeancy and others with high arc stability and good dynamic characteristics, applicable for various stainless steel welding

- Trapezoidal Wave - Soft arc brings good wetting effect to fusion pool, suited to groove welding and overhead welding

- Triangle Wave - Short peak-time and low heat-input, suitable for thin sheet welding

- Sine Wave - Arc noise is smaller and softer

Picture are for illustration purpose only, actual may vary. Specifications are subject to change without prior notice.

Lebih maklumat tentang LEEDEN HERCULES SDN BHD

Malaysia

Malaysia