Application

In the last production step, the finished pigment powders are pneumatically conveyed into packing silos. The conveying system generates very high dust levels and air movement inside the silos. To control the filling process, the levels in the silos need continuous monitoring. A high level detection switch is used for safety shutdown in case of overfilling. The pigment powder is then filled into sacks via the bottom outlet.

Your benefit

Reliable

High measurement reliability, even in extremely dusty environments

Cost effective

Maintenance-free operation

User friendly

Simple to set up

Recommended products

VEGAFLEX 82

Continuous level measurement with guided radar in filling silo

- Accurate measurement despite extremely dusty environment

- Reliable level measurement, even in media with low dielectric constant

- Simple and fast setup with display and adjustment module

Measuring range - Distance

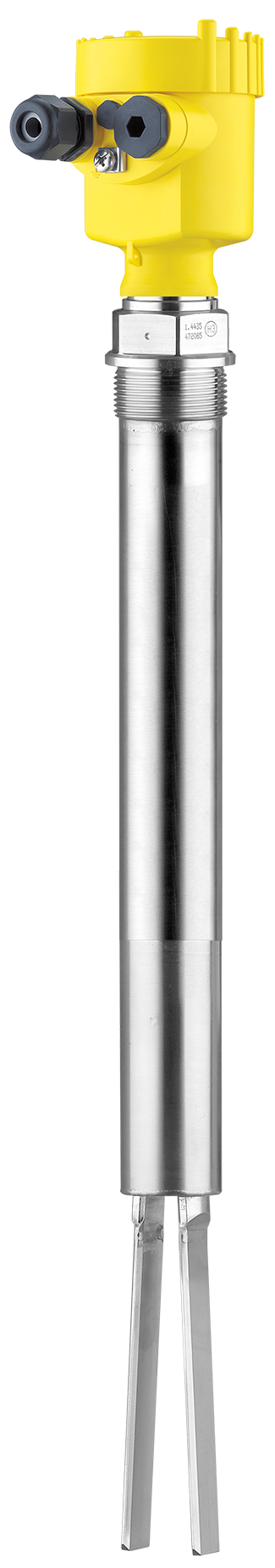

VEGAWAVE 63

Vibrating level switch for protection against overfilling

- Simple setup without calibration

- Reliable detection despite changing density of the medium

- Dependable function thanks to product-independent switching point

Version

Detection of solids in water

with tube extension

with temperature adapter

Malaysia

Malaysia