COLO powder spray booth is an economical solution for basic manual powder coating operations requiring reclaim capability. For small workshops, beginners, this manual powder booths offers a lot advantages, such as easy cleaning, simple operation and high recycling rate.

1. Dustfree workshop

Our booth built with high precision cartridge filters, effectively separating oversprayed powders from air flow, ensure dusfree workshop

2. High powder unitilization

The powders attached at filters will be released by pulse system and drop into a collector beneath the stage, this ensures high powder recycling rate and longer filter life.

3. Compact design, easy to move

Our powder booth has a space-saving design with integrated filter stage, control unit and fan, along with wheels that make it easy to move when needed.

4. Easy to clean, quick for color change

Interchangeable cartridges and a powder coated steel base section allow to easily clean the booth if color change operation is needed.

|

Booth Type |

Closed |

|

Operator dimensions |

1000width*800depth*1000mmHeight |

|

Overall dimensions |

1300width*1900depth*2100mmHeight |

|

Weight |

350kg |

|

Power supply |

Electric |

|

Nominal power |

1.5kw |

|

Voltage |

110V /220V/380V (as required) |

|

Frequency |

50-60Hz |

|

Filters |

Polyester |

|

Filters count |

2 (325*600) |

|

Filters hang type |

easy for change |

|

Filter cleaning system |

Pneumatic |

|

Air consumption |

4000m3/h |

|

Warranty |

12 months |

|

model |

Colo-0811 |

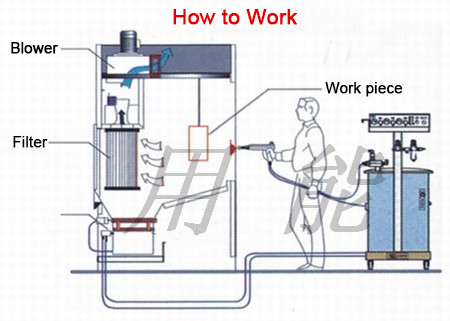

Our Powder Booths make efficient use of shop space and are designed for simple manual application with overspray reclamation. Shop air is drawn into the spray booth, and then passes through the booth's workspace into a filtered plenum integrated into the wall. The air is filtered and then discharged to the outside atmosphere or routed back into the room.