Safe integration for a productive interaction

Safe EFI-pro system is the result of the consistent development of the successful EFI interface and enables intelligent safeguarding of AGVs, robots and other challenging applications. The industrial Ethernet-based EFI-pro network technology enables the quick exchange and transmission of safe and non-safe data throughout all levels of communication. The central component is the EFI-pro gateway. It ensures safe and fast integration of innovative sensor solutions from SICK as well as direct integration of robot controls into the Flexi Soft safety controller via EtherNet/IP™ CIP Safety™. The Safe EFI-pro system is therefore a crucial enabler for implementing Industry 4.0.

Safe EFI-pro System AT A GLANCE

Benefits

-Efficient interplay in the safety system: Networking of safety sensors, safety controllers and actuators connected via Ethernet/IP™ CIP Safety™

-Fast, intuitive commissioning: Safety Designer for the configuration of SICK system components and clever connection technology

-Safe productivity: Combination of safe motion monitoring, simultaneous protective field monitoring and extended network integration

-Optimized processes: Extensive diagnostic options via Safety Designer and data via Ethernet from the field level into the cloud

-Safe investment thanks to industrial Ethernet technology

Features

-Industrial Ethernet-based, safe network technology

-Configuration via Safety Designer

-Safe integration of up to 6 safety laser scanners

-Safe integration of robot controls via Ethernet/IP™ CIP Safety™

-Safe, integrated movement monitoring

-Simultaneous monitoring of up to 48 protective fields

ADVANTAGES

Efficient interplay

Efficient interplay

The Safe EFI-pro system combines the tried-and-proven modular Flexi Soft safety controller with the microScan3 – EFI-pro and nanoScan3 – EFI-pro safety laser scanners. Safe device communication via the EFI-pro gateway enables quick and easy networking of the system components. Actuators of other manufacturers, such as robot controls, can be safely connected via EtherNet/IP™ CIP Safety™.

The Flexi Soft safety controller with EFI-pro gateway ensures intelligent networking of the system components.

The microScan3 and nanoScan3 safety laser scanners are reliable and resilient thanks to the innovative safeHDDM® scanning technology.

For example, robot controls can be safety integrated into the safety system via EtherNet/IP™ CIP Safety™.

Safe networking via EFI-pro makes it easy to use innovative sensor functions.

Safe productivity

Safe productivity

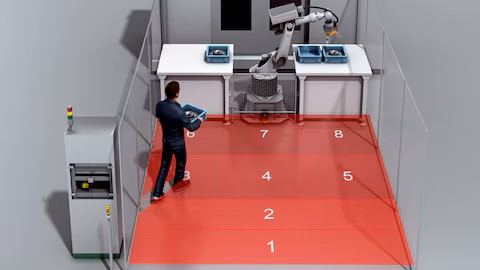

Up to six microScan3 and/or nanoScan3 safety laser scanners can be networked to ensure safe and adaptive perception of the environment. Every device offers up to eight simultaneously monitorable protective fields and up to 128 monitoring cases. Together with the safe motion control function of the Flexi Soft safety controller, monitoring cases can be adapted dynamically to the respective monitored area. This increases the productivity of collaborative machines.

More functions for challenging safety applications

Dynamic monitoring case switching, for example depending on the speed and steering angle of an AGV.

Simultaneously monitorable protective fields for efficient, adaptive robot behavior.

https://youtu.be/m-a2SgQvknY

Mobile robots in use with the Safe EFI-pro System.

Use the extended functions for higher productivity with extensive safety monitoring.

Time- and cost-saving configuration and commissioning

Time- and cost-saving configuration and commissioning

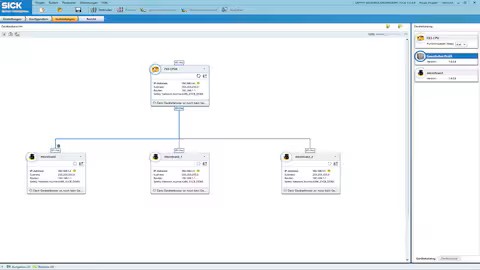

The commissioning of the system components is quick and easy with the Safety Designer engineering tool. Thanks to the drag-and-drop function, networking between the safety controller and the safety sensor is done in seconds. The smart connectivity with a standardized plug connector and the use of Industrial Ethernet (IEEE 802.3) also reduce cabling work.

Intuitive engineering tool and reduced cabling work

License-free and intuitive Safety Designer engineering tool for system component configuration and diagnostics.

Safety Designer automatically detects all devices. Networking is then done simply with drag-and-drop.

Fast cabling of system components thanks to standardized Ethernet technology.

The configuration of system component with the intuitive Safety Designer engineering tool and cabling via Industrial Ethernet (IEEE 802.3) ensure time- and cost-efficient commissioning.

Optimized processes

Optimized processes

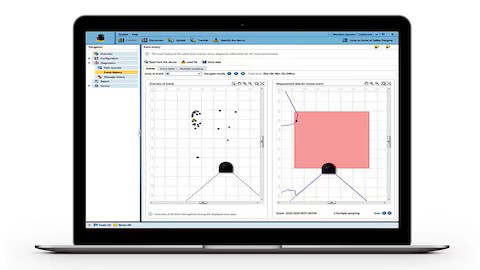

Comprehensive diagnostic options - data up into the cloud

Quick analysis, for example of machine downtimes, thanks to comprehensive diagnostic options in the Safety Designer.

Integration into all common fieldbus systems is done via additional non-safety-related gateways.

Transport of process and diagnostic data up into the cloud enables centralized analysis and optimization of processes.

Optimize your processes thanks to extensive diagnostic options in Safety Designer and constant data availability up into the cloud.