Natural protection by material

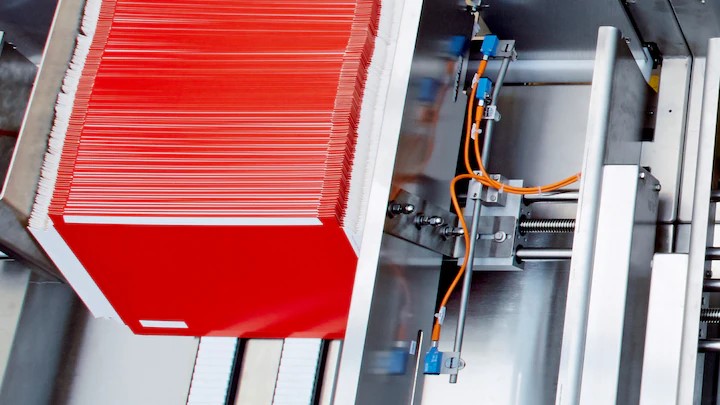

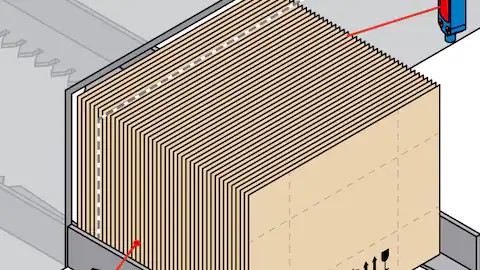

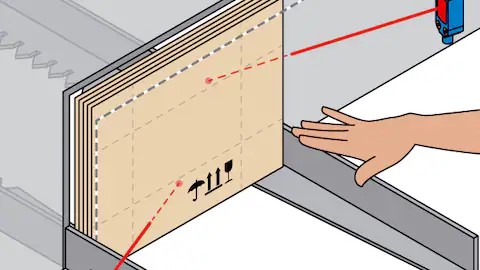

Increase the safety and productivity of packaging machines with the modular Safeguard Detector safety system. The Safeguard Detector consists of two MultiPulse photoelectric proximity sensors, and the Flexi Soft safety controller or the UE410-SD evaluation module. The Safeguard Detector safely detects whether a movable physical guard is located at a previously defined position, e.g., the packaging material in the carton magazine of packaging machines. If there is sufficient packaging in the carton magazine, then it is not possible to reach into the hazardous area while the machine is running.

Safeguard Detector AT A GLANCE

Benefits

-With the certified safety system for material feeding, you save time and money: An additional safety assessment is not necessary, and elaborate mechanical protection systems are not required

-Implement the system in tight spaces thanks to the very compact sensor housing

-You can count on the reliable detection of different materials such as cardboard or plastic

-You can also integrate the system into existing safety controllers and easily retrofit existing machines

-Take advantage of fast format changeovers and high machine availability

Features

-Certified up to PL d (EN ISO 13849), performance class D (IEC/TS 62998)

-High sensor availability in a miniature housing

-Reliable object detection, remission factor: 6% to 90%

-“Flexi Soft”, “Box”, “Software” system variants

-Background and foreground suppression protects against manipulation

-Detection distance: Up to 150 mm

ADVANTAGES

TÜV-certified safety system for safe material feed

TÜV-certified safety system for safe material feed

The Safeguard Detector ensures high productivity while protecting machine operators: The TÜV-certified safety system enables simple format and material changes in feed magazines and therefore efficient production processes.

The Safeguard Detector makes it possible to eliminate mechanical tunnel systems. This means you can significantly reduce the space required by the machine.

Thanks to the TÜV certification of the Safeguard Detector, you do not need any additional safety assessment. This means you can save time and money during commissioning and documentation.

High productivity with unlimited safety

So that nothing stands in the way of your machine productivity

So that nothing stands in the way of your machine productivity

With rugged sensors and flexible machine controller within a safety system, the Safeguard Detector ensures the safety of people and fast setup of packaging materials and loading of the feed magazine. The system also detects whether only the desired material is fed to the machine.

Two MultiPulse photoelectric proximity sensors reliably detect whether the feed magazine of the packaging machine contains enough material.

If the material is almost empty, the sensors detect that material is missing. In this case, the hazardous area is no longer sufficiently protected. The machine is switched off in a safe manner until new material is filled.

The Safeguard Detector reliably detects various types of packaging, for instance cardboard boxes and plastic containers. This means you can use the system in many applications.

High reliability for efficient processes

High flexibility for new and existing machines

High flexibility for new and existing machines

Whether you are planning a new machine or want to retrofit an older one, the modular design of the Safeguard Detector means it can be adapted to the requirements of your protective device. Simply select the system variant that best fits your needs.

“Flexi Soft” system variant

This variants consists of the software, the MultiPulse photoelectric proximity sensors, and the Flexi Soft safety controller. The Flexi Soft impresses with easy configuration and diagnostics. Additional safety components can be integrated quickly. This allows for high process efficiency and flexibility.

“Box” system variant

If a safety controller has already been implemented in your machine, you can expand it with the “Box” variant with MultiPulse photoelectric proximity sensors and the UE410-SD evaluation module. This allows you to add preconfigured function blocks to the system, thus increasing safety.

“Software” system variant

If the Flexi Soft safety controller is already used in your machine, you can also use the system variant with software. This makes it possible to quickly retrofit older machines and benefit from reliable productivity.

Modular system to fit your needs