Fine positioning solution for single- and double-deep racking

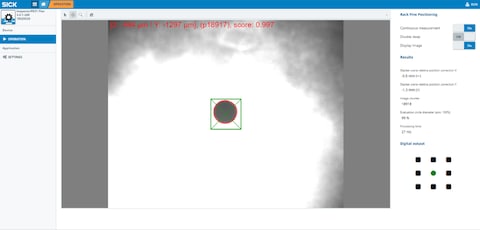

The InspectorP Rack Fine Positioning is an easy-to-use yet flexible vision sensor that guides fine positioning of stacker cranes, or other automated storage and retrieval systems, in X and Y. The large measurement range allows for double-deep racking using the same sensor for both near and far range. Racks are reliably located using drilled holes only or reflectors, even with challenges such as stains or reflections. InspectorP Rack Fine Positioning offers plug-and-play simplicity out of the box by including pre-assembled illumination, pre-focused optics and pre-installed software.

InspectorP Rack Fine Positioning AT A GLANCE

Benefits

-Save rack space to maximize storage capacity with high-precision positioning

-Handle near and far range in double-deep racking with only one sensor

-Compact, pre-configured, stand-alone device for integration

-Flexible system integration through multiple connectivity options

-Little to no training needed thanks to smart hardware features and simple web GUI

-Allows using only holes for positioning, even with challenges such as stains or reflections

-Image monitoring and logging of hard-to-reach places

-Cold store option available

Features

-Single- and double-depth rack storage using one device

-User-friendly web interface

-PROFINET and digital output

-Rugged metal housing including IP67 protective hood

-LEDs, laser alignment aid, on-device buttons and optional microSD memory card

-Pre-assembled, pre-focused and pre-configured

-Access to image data

ADVANTAGES

Save rack space to maximize storage capacity with high-precision positioning

InspectorP Rack Fine Positioning offers plug-and-play simplicity out of the box by including pre-assembled illumination, pre-focused optics and pre-installed software.

Allows using only holes for positioning, even with challenges such as stains or reflections.

Little to no training needed thanks to smart hardware features and simple web GUI.

The InspectorP Rack Fine Positioning is an easy-to-use yet flexible vision sensor that guides fine positioning of stacker cranes or other automated storage and retrieval systems.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

More detail about Truserv Technologies (M) Sdn Bhd