CO laser engravers get their name because they use CO gas as their laser medium. It works by generating plasma from CO gas inside of a tube, amplifying that light between a reflective mirror and output coupler, and then output as a laser beam. The output laser beam has a wavelength of 10600 nm and due to this long wavelength they are extremely heat dependent. They are great for material removal and for marking organic materials like cardboard, plastic, glass, and wood.

CO laser markers rely on heat to mark parts, making them perfect for cutting applications. In fact, CO lasers are commonly used for cutting holds, gate cutting, and sticker half-cutting applications.

Compared to mechanical cutting tools, CO laser markers are fully automatable, flexible, and almost entirely maintenance free.

Applications :

- Marking on the surface of packaging bottles of cosmetics,

- Medicines,

- Food,

- Other polymer materials.

Applicable materials :

- Glass ware,

- Metal,

- Plastic,

- Silica gel,

- Flexible PCB etc.

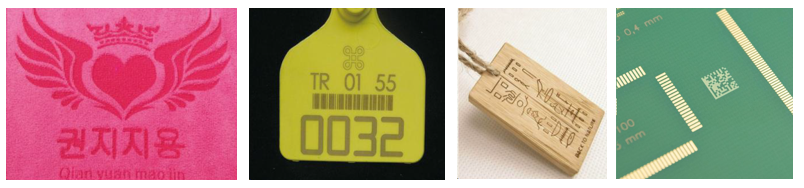

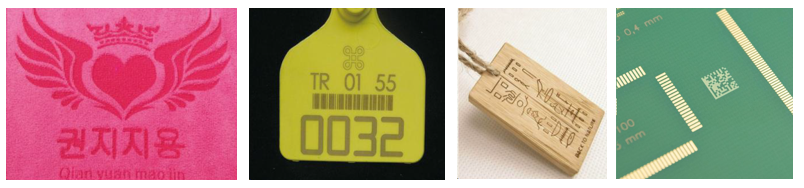

Typical cases:

- Photovoltaic solar glass marking,

- Plastic keys,

- Gift marking,

- Communication equipment,

- Silicon wafer micropores.

Malaysia

Malaysia