Description

COPPUS Jectair® HP and Hornet HP

High-Performance, Highly Efficient Venturi Air Movers

The unmatched performance of the COPPUS Jectair® HP is recognized throughout the industry. When compared with older-style air horns, the patented air mixing chamber of the Jectair® HP can produce up to a 40:1 air flow conversion and up to 26 percent savings on compressed air consumption.

Operating Principle: Compressed air or steam is admitted into the Jectair through a single inlet connection in the housing leading to the mixing chamber. The air or steam jetted from the nozzle creates a “Venturi” action that induces a large volume of surrounding air to enter the Jectair through the aerodynamic inlet bell. The air is then discharged at high velocity through the horn-shaped diffuser.

Note: Operating efficiency depends on compressed air volume and pressure (see charts)

Features & Advantages: (Jectair)

- Standard Jectair in five sizes: 3SHP, 3HP, 6HP, 8, or 9

- Heavy-gauge steel diffusers; aluminum diffusers available on 3HP & 6HP model

- Compressed air or steam operated

- Air flows range from 1,370 to 8,900 cfm (2,328 to 15,121 m3/hr)

- Induction ratios up to 40:1

- Multiple expansion nozzles machined into housing

- High static pressure capabilities

- No moving parts; virtually maintenance free

- Static bonding cable with spring tension grip and replaceable contact tips.

- Easily attach duct to outlet diffuser end

- Inlet duct adapter available (optional)

- Tripod for stationary mounting available (optional)

Features & Advantages: (Hornet HP)

- Hornet HP models available in three sizes: 3SHP, 3HP, & 6HP

- Features a lightweight, shock-resistant, conductive polymer diffuser that is virtually indestructible

- Polymer safely dissipates static electricity charges

- Diffuser is constructed of linear low-density polyethylene

- UL 94 rating with maximum operating temperature of 160°F (93°C)

- Compressed air operated only

- Air flows range from 1,370 to 8,900 cfm (2,328 to 15,121 m3/hr)

- Induction ratios up to 40:1

- Multiple expansion nozzles machined into housing

- High static pressure capabilities

- No moving parts; virtually maintenance free

- Static bonding cable with spring tension grip and replaceable contact tips.

- Easily attach duct to outlet diffuser end

- Inlet duct adapter available (optional)

- Tripod for stationary mounting available (optional)

Safety Precautions:

- Use bonding cables when operating in hazardous locations to prevent static electricity discharges

- Secure unit before admitting compressed air (or steam) to prevent damage or injury from high-reaction force

- Do not allow solid objects or debris to enter inlet housing during operation

- When exhausting fumes from an enclosed vessel, take care not to create a vacuum that could collapse the vessel

Accessories:

- Inlet Duct Adapter (3SHP, 3HP, 6HP, 8 & 9)

- Pipeline Adapter (3HP & 6HP)

- Tripod Stands (3SHP, 3HP & 6HP)

- Filter Sock (6HP only)

- Duct (8” Heavy duty, Conductive or Polyvinyl – 3SHP & 3HP)

- Duct (12” Heavy duty, Conductive or Polyvinyl – 6HP)

- Duct (16” Heavy duty, Conductive or Polyvinyl – 8 & 9)

- Duct Canisters (8”, 12” & 16”)

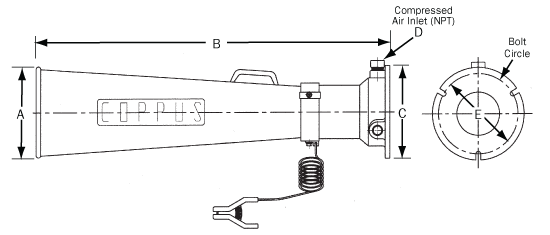

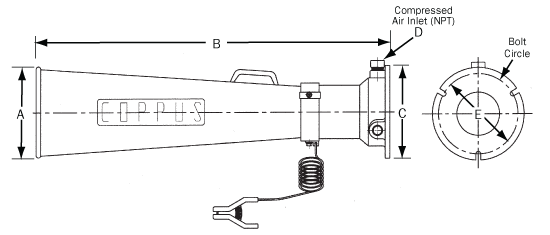

Dimensions:

| PHYSICAL DIMENSIONS |

| Jextair |

A |

B |

C |

D |

E |

No. |

Width |

Dust Size |

Net Wt. |

| in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

lbs |

kg |

| 35-HP |

6.0 |

152 |

16.5 |

419 |

7.5 |

190 |

0.5 |

13 |

6.5 |

165 |

3 |

0.4 |

10 |

8 |

203 |

6 |

2.7 |

| 3-HP |

7.3 |

185 |

33.0 |

838 |

7.5 |

190 |

0.5 |

13 |

6.5 |

165 |

3 |

0.4 |

10 |

9 |

4.1 |

| 6-HP |

12.0 |

305 |

44.2 |

1,123 |

11.5 |

292 |

1 |

25 |

10.8 |

274 |

3 |

0.4 |

10 |

12 |

305 |

21 |

9.5 |

| 8 |

14.0 |

356 |

46.0 |

1,168 |

14.3 |

363 |

1 |

25 |

13.5 |

345 |

3 |

0.5 |

13 |

14 |

356 |

35 |

15.9 |

| 9 |

14.0 |

356 |

46.0 |

1,168 |

16.8 |

427 |

1 |

25 |

15.3 |

387 |

10 |

0.9 |

23 |

42 |

19 |

Performance:

| PERFORMANCE THROUGH VARIOUS LENGTHS OF DUCT (80 PSIG or 7 KG/CM2) |

| Jectair |

Free Air |

20 ft (6 m) |

30 ft (9 m) |

40 ft (12 m) |

50 ft (15 m) |

| cfm |

m3/hr |

cfm |

m3/hr |

cfm |

m3/hr |

cfm |

m3/hr |

cfm |

m3/hr |

| 3-HP |

1,700 |

2,888 |

1,550 |

2,634 |

1,480 |

2,515 |

1,410 |

2,396 |

1,350 |

2,294 |

| 6-HP |

4,500 |

7,645 |

4,020 |

6,830 |

3,860 |

6,558 |

3,715 |

6,312 |

3,580 |

6,083 |

| 8 |

6,250 |

10,620 |

5,550 |

9,431 |

5,280 |

8,972 |

5,050 |

8,581 |

4,850 |

8,241 |

| 9 |

8,000 |

13,592 |

6,850 |

11,640 |

6,550 |

11,130 |

6,250 |

10,620 |

6,000 |

10,195 |

Efficiency:

| EFFICIENCY AT SELECT INLET PRESSURES |

| Inlet Pressure |

Jectair |

Air Flow |

Air Consumption |

Induction Ratio |

Block Tight

Static Pressure |

| cfm |

m3/hr |

cfm |

m3/hr |

in |

mm |

60 psig

or

4.2 kg/cm2 |

3S-HP |

1,370 |

2,328 |

47 |

80 |

29.1 |

5.8 |

147 |

| 3-HP |

1,520 |

2,595 |

47 |

80 |

32.3 |

5.8 |

147 |

| 6-HP |

3,980 |

6,762 |

98 |

167 |

40.6 |

4.3 |

109 |

| 8 |

5,600 |

9,515 |

178 |

302 |

31.5 |

3.9 |

99 |

| 9 |

6,880 |

11,096 |

265 |

450 |

25.8 |

5.5 |

140 |

80 psig

or

5.6 kg/cm2 |

3S-HP |

1,530 |

2,600 |

61 |

104 |

25.1 |

7.5 |

191 |

| 3-HP |

1,700 |

2,888 |

61 |

104 |

27.8 |

7.5 |

191 |

| 6-HP |

4,500 |

7,645 |

126 |

214 |

35.7 |

5.6 |

132 |

| 8 |

6,250 |

10,620 |

233 |

396 |

26.8 |

5.2 |

132 |

| 9 |

8,000 |

13,592 |

366 |

571 |

23.8 |

6.8 |

173 |

100 psig

or

7.0 kg/cm2 |

3S-HP |

1,660 |

2,820 |

72 |

122 |

23.0 |

8.9 |

224 |

| 3-HP |

1,860 |

3,160 |

72 |

122 |

25.8 |

8.9 |

224 |

| 6-HP |

4,870 |

8,274 |

153 |

260 |

31.8 |

6.7 |

170 |

| 8 |

6,750 |

11,469 |

282 |

479 |

23.9 |

6.2 |

157 |

| 9 |

8,900 |

15,121 |

410 |

697 |

21.7 |

7.7 |

196 |

| * Maximum Operating Pressure 150 psig (10.5 kg/cm2) |

| * Induction Ratio = Air Flow/Air Consumption |

Noise:

| JECTAIR DECIBEL LEVEL |

| Model |

Pressure |

Decibel |

| psig |

dBa |

| Jectair 3 |

40 |

81 |

| 60 |

85 |

| 80 |

88 |

| Jectair 6 |

40 |

85 |

| 60 |

89 |

| 80 |

92 |

| Jectair 8 |

40 |

87 |

| 60 |

91 |

| 80 |

94 |

| Jectair 9 |

40 |

88 |

| 60 |

92 |

| 80 |

95 |

More detail about KSJ Global Sdn Bhd

Malaysia

Malaysia