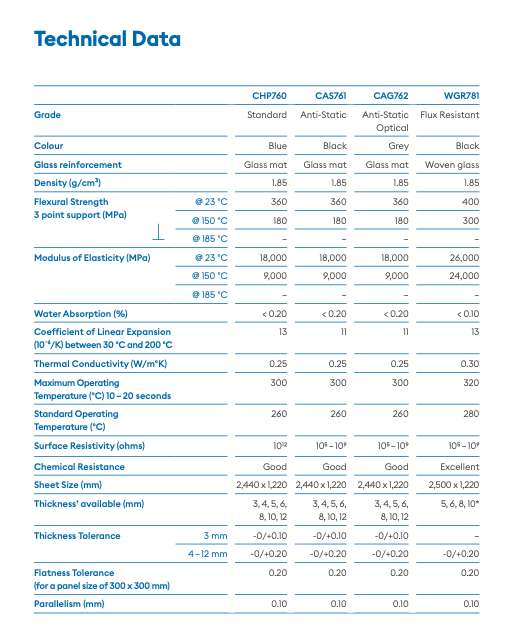

Durostone® WGR781 is a woven glass laminate which has been specially formulated to withstand extreme temperatures and aggressive fluxes. Fluxes containing halides or halogen activators can reduce a material´s lifespan, but Durostone® WGR781 can run many thousands of cycles without any adverse effect. The woven glass reinforcement ensures that the flux does not penetrate the solder pallet surface and expose fibres.

In the wave soldering process, a combination of flux, temperature and process cycle time can result in a reduced lifespan of standard solder pallet materials.

The solution is Durostone® WGR781, a woven glass laminate which has been specifically formulated to withstand extreme temperatures and aggressive fluxes.

Fluxes containing halides or halogen activators can reduce a material’s lifespan but Durostone® WGR781 is designed for a very high cycle repetition. The woven glass reinforcement ensures that the flux does not penetrate the solder pallet surface and expose fibres.

The resin used to produce Durostone® WGR781 can operate at a continuous temperature of 280 °C. The material also displays excellent mechanical properties and provides the necessary dimensional stability at elevated temperatures in the wave soldering process. Due to the improved material properties, the use of titanium inserts can often be eliminated, depending on the application conditions.

Durostone® WGR781 has excellent machining properties, with thin wall thicknesses possible.

Malaysia

Malaysia