The term “DesiUS” stands for “disintegration ultrasound system”. The disintegration process which forms the basis of DesiUS was developed by Weber Ultrasonics in collaboration with the Fraunhofer Institute, and was optimised by Weber Entec through the use of the BioPush reactor.

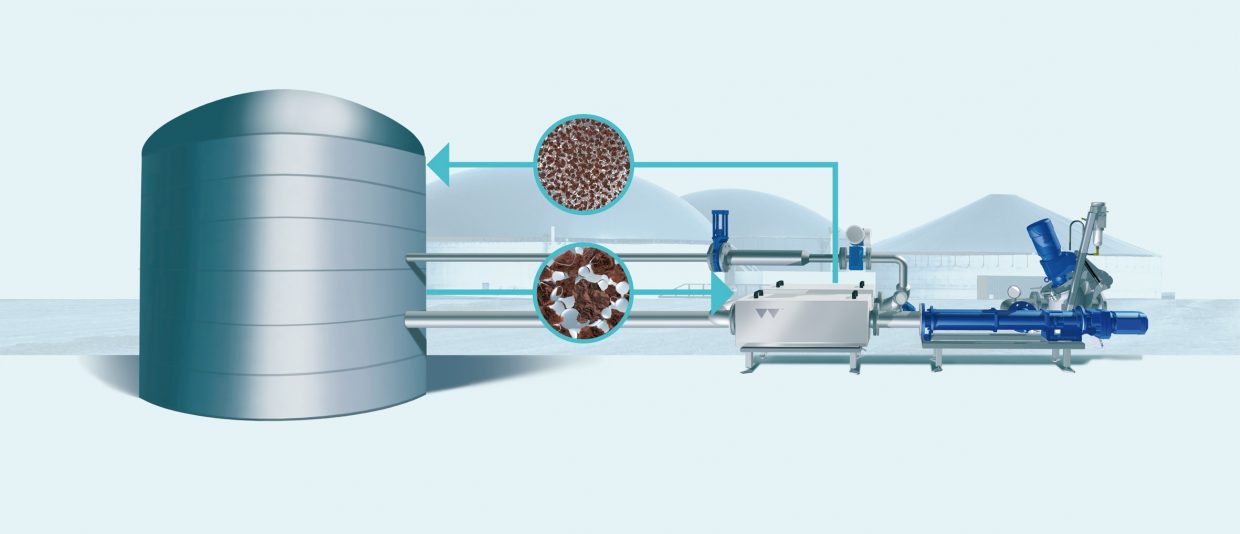

DesiUS (Disintegration Ultrasound System) represents energy-efficient and process-robust cell opening technology combined with exceptionally high efficiency. The robust and completely maintenance-free construction of the BioPush reactor allows a simple and uncomplicated structure. The ultrasonic reactors of the turnkey constructed plant are charged via a screw pump. The substrate is routed through the sound field at a specific speed in such a manner that the specific energy input required for treating the substrate is ideally achieved. A macerator protects the machine from foreign objects and provides coarse homogenization upstream, in order to achieve optimal coupling of the ultrasound. A PLC-supported control system enables robust and trouble-free operation. In addition, the machine is equipped with sensors that monitor temperature, pressure and volumetric flow.

at biogas plants

LONG LIFETIME, OPERATIONAL RELIABILITY and ZERO MAINTENANCE

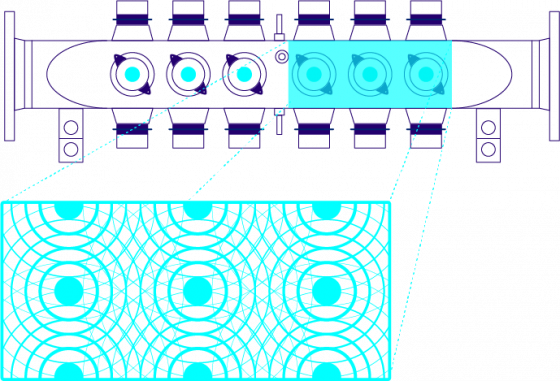

The BioPush Ultrasound reactor solves the problems of the other disintegration systems. Because biomasses with a typical solids content between 8 % and max. 13 % have a relatively high viscosity, more effort is usually required in traditional plants in order to ensure an effective coupling of the ultrasound to the medium. Because the cavitation performance of the ultrasound becomes more damped as the viscosity of the medium increases, the medium must therefore be passed as close as possible to the sonotrode. Although this could be achieved constructionally by means of a sufficiently small pipework cross-section, it is not possible to implement it in this way, because the sonotrodes tend to become affected by blocking and “tressing” from fibrous components, both in substrates from biogas plants using renewable raw materials and also in sewage sludges. The results are a high level of sound damping, and therefore reduced energy efficiency.

The BioPush reactor developed by Weber Entec specifically for the treatment of biomasses tackles this problem. The structure practically precludes blockages and tressing. The working life of the BioPush reactor is several times longer than with classical rod sonotrodes in the biomass area.

What is so special?

The core technology of DesiUS is the ultrasonic technology from Weber Ultrasonics. The BioPush reactor, which was specially developed for the treatment of biogenic sludges, takes into account the high requirements placed on the disintegration process and in many aspects is significantly better than the conventional rod transducer or sonotrode technique.

In the early days of ultrasonic disintegration, the use of the rod transducers technology turn to be problematic because of the enormous wear and the use of the sonotrodes in the biomass field.

These findings led to a rethinking at Weber Entec and Weber Ultrasonics. A reactor specifically designed for the treatment of biomass has been developed.

The problems of traditional rod oscillator technology listed below arise mainly because of the direct contact of the sludge with the rod transducer. The aggressive cavitation force, which is wanted and required to achieve the intended effect, inevitably leads to an unstable process in the biogenic sludges.

That’s why Weber Entec has developed the BioPush reactor. The innovation of this approach is that the ultrasound is fixed on the outside of the reactor and thus no disrupting/interfiering body is left in the medium to be treated.

更多 HSA ASIA SDN BHD 相关资料

更多 HSA ASIA SDN BHD 相关资料

Malaysia

Malaysia