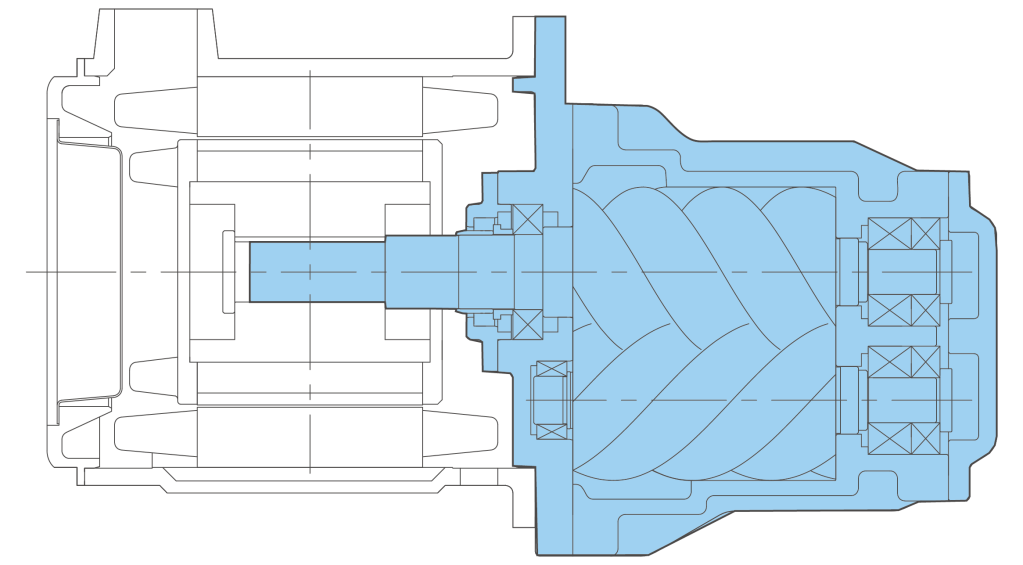

TMV Series are equipped with highly efficient air-end. The newest design includes Two -Motors, Two-Stages, Direct-Drive compression, variable frequency and without gears, etc. Reach to the best performance.

Perfect craftmanship with high efficiency, easy operation & easy maintenance

Two-layer filter design provides high frequency air, and prevents from the suction of the dirt and impurities; not only can reduce the consumption of the air compressor, but also can reduce the noise of running.

With the permanent magnetic, two-stages motor and the direct drive coaxial design, the air end not only is space-saving, but also runs with at the lowest energy consumption. No matter in the need of variable air volume or pressure change, the air end can always run in the best condition, which improves the work efficiency.

Variable frequency controller heavy duty type can work in higher loading, stabilize pressure according to the inquiry with no speed, and also can adjust parameter to change working pressure with a quick and easy way.

High air volume certainly air cooled, low noise, 3dB lower than axial fan. Inner rotor fan, motor taking the hot air, no risk of high temperature damage and high durability, enable the air end to operate in the most efficient temperature.

With the vertical design, it facilitates the clearance of air end, maintenance of air compressor, and the oil drain, and also economize the cost on equipment maintenance.

Permanent magnetic motor has higher efficiency than IE4 motor

Wider variable frequency range: 30%~100%, which ensures better energy-saving performance at lower running speed; the permanent magnetic motor is 35% smaller than ordinary motor, which is minimize space occupation.

With F class insulation, 65K low working temperature-rise, to ensure the permanent magnetic motor in good performance, more reliable, durable and long service life.

The permanent magnetic coaxial design reduces the mechanism consumption of coupling and motor bearings, and also improves the compression efficiency; minimizes 20% the air compressor volume; can use space more effectively.

Isobaric compression lowers down the compressing ratio, which increase the service life of seal gasket and raise it’s volumetric efficiency.

Injecting oil to cool down the compressed air between the first stage and the second stage, to reach to isothermal compression operation for energy-saving.

The traditional two-stage gear-shift design only has the best compression efficiency at its fixed setting-pressure. It’s difficult to maintain the best efficiency when the air consumption or pressure is change. TMV models overcome the general fixed gear-shift problem. It can automatically adjust the running speed of each motor while the discharged air pressure is changed and always keep the air end in optimal running efficiency.

SWAN air compressor cabinet type use the high rigid structure sheet metal which is applied with sound-absorbing cotton and high anti-noise design to keep the compressor running in silence and low vibration.

| Model | Power (HP) | Power (kW) | Working Pressure (kg/cm²) | Capacity (m³/min) | Dimension (mm) (L*W*H) |

|---|---|---|---|---|---|

| TMV11Z | 15 | 11 | 8 | 1.75 | 1250X795X1585 |

| TMV11TU | 15 | 11 | 8 | 1.88 | 1450X795X1390 |

| TMV15 | 20 | 15 | 8 | 2.40 | 1250X795X1585 |

| TMV15TU | 15 | 22 | 8 | 2.65 | 1450X795X1390 |

| TMV22 | 30 | 22 | 8 | 3.50 | 1190X1145X1570 |

| TMV22TU | 30 | 22 | 8 | 3.99 | 1190X1145X1570 |

| TMV37 | 50 | 37 | 8 | 6.37 | 1485X1145X1750 |

| TMV37TU | 50 | 37 | 8 | 6.64 | 1250X1220X1770 |

| TMV75TU | 100 | 75 | 8 | 15.5 | 2335X1600X2140 |

| TMV110TU | 150 | 110 | 8 | 22.8 | 1485X2770X1990 |

| TMV160TZ | 215 | 160 | 8 | 31.8 | 2950X1600X2300 |

Malaysia

Malaysia