More flexibility and efficient communication

The AS30 array sensor operates on the proximity scanning principle. It detects even the slightest differences in grayscale values within the field-of-view. Positioning of, for example, a paper web based on the web edge or a contrast line is only one of many possible applications. Widths, diameters, and gaps can also be detected. In reflector mode, the AS30 can even detect transparent materials.

AS30 AT A GLANCE

Benefits

-Higher reliability and more stable processes thanks to teach-in of contrast edges

-TFT display for flexible configuration options and easy commissioning

-Various operating modes provide the right defaults for every application

-High repeatability of up to 30 µm

-No fine positioning of the sensor required thanks to the large field of view of up to 165 mm

-IO-Link and the SOPAS ET software ensure easy configuration

-Efficient communication and predictive maintenance through smart sensor functionality

Features

-Teach-in of selected edges possible

-Full color TFT display

-Various operating modes for different applications

-Core and Prime variant for different fields of application

-Large measuring range of up to 165 mm

-Sensing distance of 25 mm or 100 mm

-Repeatability of up to 30 µm

ADVANTAGES

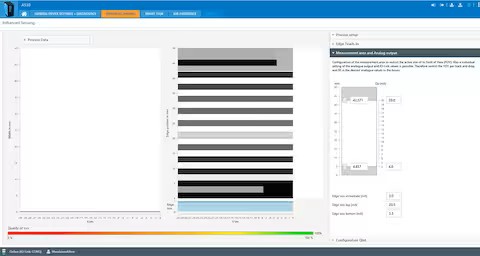

More process reliability through edge and area teach-in

The AS30 provides the option to teach-in edge positions or areas. The sensor can then detect a taught-in contrast edge while ignoring spurious edges in the surroundings or on the object to be detected. This results in increased process reliability and stability. The area teach-in can be used to define detection zones, which simplifies position control.

Edge and area teach-in can be performed directly via the control panel or via IO-Link.

The edge teach-in is simple and intuitive to perform via the TFT display or SOPAS ET. A few clicks is all it takes to teach-in the desired edge

The area teach-in is used to define switching zones around the desired edge position. This, too, requires only a few clicks to achieve effective area control

The AS30 enables you to achieve more process reliability and save time during commissioning. The sensor can be taught-in, and switching zones defined in just a few clicks.

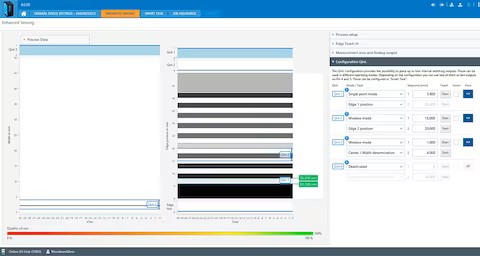

High application flexibility through sensor configuration and IO-Link

Through the flexible configuration of the array sensor via IO-Link, the SOPAS ET configuration software, and the intuitive full color TFT display, the AS30 can solve a wide variety of application tasks. Thanks to various preset operating modes, the AS30 can be employed, for example, for edge guiding, object positioning or width measurement. Through a simple switchover from proximity scanning mode to reflector mode, the AS30 is able to detect opaque and transparent objects.

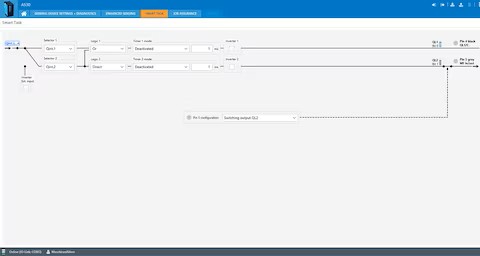

Flexible application: the size of the measuring range can be changed and adapted to the application conditions

Easy to configure: Various position zones, thresholds or widths can be configured and monitored by means of different switching criteria

Smart sensor: Various switching outputs and external inputs can be logically linked. This makes the sensor flexibly configurable for a wide variety of applications

The AS30 lets you solve a wide variety of tasks with just one device. Whether it be edge or width measurement, opaque or transparent materials: The AS30 is the right solution.

Higher detection performance thanks to external illumination

By using an external illumination unit for array sensors such as the AS30, very good results can be achieved in particular when detecting dark material edges. With the powerful external ELA illumination unit, SICK offers an accessory that can be used together with the AS30 in numerous applications and can eliminate the need for expensive vision systems. The ELA can also be used as a backlight.

Using the ELA as a backlight, it is also possible to detect internal edges such as embossing lines.

Using the ELA, material edges are clearly recognizable even through semi-transparent materials such as battery separator films.