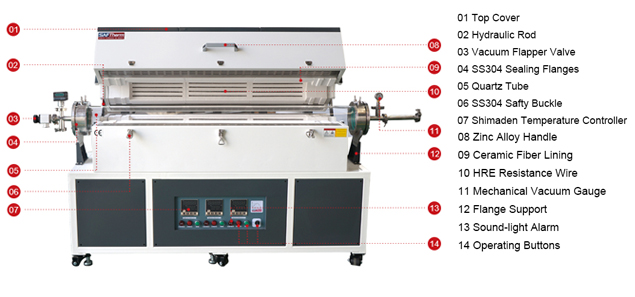

The multi-heating zone tube furnace is composed of heating system, temperature control system, working tube and sealing kit. It can work under vacuum or atmosphere condition to meet various CVD process requirements. Multiple heating zones can help to achieve high uniformity temperature field conditions, and can also be applied to material temperature field gradient experiments. This product is widely used in sintering and heat treatment of graphene materials, lithium battery positive and negative electrode materials, semiconductor materials, new energy and new material industries.

Multi-layer insulation design, composed of lightweight alumina ceramic fiber and high-quality insulation board backing, does not contain asbestos components, low heat loss and low energy consumption

|

Model |

Heating zonemm

|

Tube size (mm)

|

Max temp |

Voltage |

Power |

Heating element |

Temp accuracy |

|

MTG-40-12-6S |

1200 |

Φ40×1800 |

1200 |

380V |

10KW |

HRE |

±1 |

|

MTG-60-12-6S |

1200 |

Φ60×1800 |

1200 |

380V |

15KW |

HRE |

±1 |

|

MTG-80-12-6S |

1200 |

Φ80×1800 |

1200 |

380V |

16KW |

HRE |

±1 |

|

MTG-100-12-6S |

1200 |

Φ100×1800 |

1200 |

380V |

18KW |

HRE |

±1 |

|

MTG-120-12-6S |

1200 |

Φ120×1800 |

1200 |

380V |

22KW |

HRE |

±1 |

|

MTG-150-12-6S |

1200 |

Φ150×1800 |

1200 |

380V |

25KW |

HRE |

±1 |

|

MTG-200-12-6S |

1200 |

Φ200×1800 |

1200 |

380V |

30KW |

HRE |

±1 |