More efficiency with safety

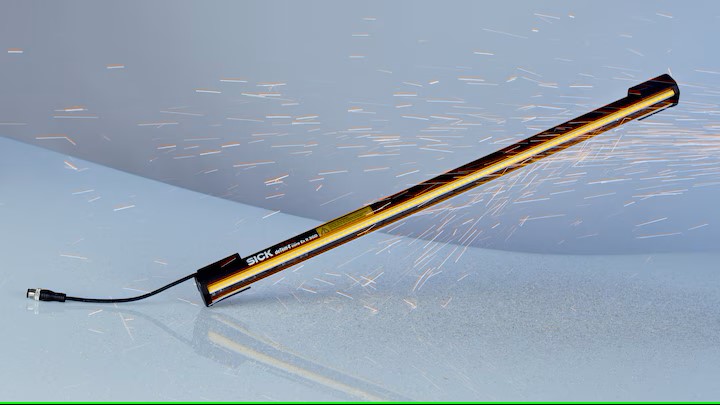

The deTem multiple light beam safety devices offer high flexibility and efficiency for access protection as well as for entry and exit monitoring with muting. The deTem features a compact housing and stands out not only due to its smart functions, but also thanks to its innovative diagnostic options. These ensure high machine availability and enable process optimization. Housing design and connectivity are standardized and therefore reduce installation work. Thanks to this standardization, numerous SICK accessories are also compatible with the deTem. SICK also offers deTem variants for explosion-hazardous areas and for applications which require enclosure rating IP69K.

deTem AT A GLANCE

Benefits

-Increase productivity in access protection as well as entry and exit monitoring with muting thanks to the processing of sensor data

-Minimize installation work and profit from standardized implementation of the deTem into your machine design

-Take advantage of the benefits of quick and easy device alignment

-Save time and money thanks to easy commissioning and configuration

-You can also count on the deTem in harsh environments

Features

-Smart Sensor: diagnostic data via IO-Link or NFC and the SICK Safety Assistant app

-Compact housing, standardized connectivity, compatible accessories

-Integrated alignment aid with status LEDs directly on the device

-Configuration of all functions without software

-Variants for explosion-hazardous areas as well as enclosure rating IP69K

ADVANTAGES

Intelligent solution – from connection to data use

Intelligent solution – from connection to data use

Whether in intralogistics, consumer good production, mechanical engineering or other areas: wherever multiple light beam safety devices deliver process-relevant data, production processes can be made much more efficient. This is also the case with our smart deTem products, which enable process optimization in real time with their innovative diagnostic functions. In addition, deTem products are quick and easy to connect, align, configure and implement into your machine design.

NFC and IO-Link: these innovative technologies support fast configuration and extensive diagnostics

The integrated alignment and status display with multi-colored status LEDs and a top LED is especially user-friendly

Housing, connections and accessories are standardized for all deTem and deTec variants

Smart, fast and future-proof: for smooth production processes

Impressive flexibility: deTem A/P

Impressive flexibility: deTem A/P

With the deTem A/P series, you remain flexible for access protection and muting applications. The photoelectric sensor consists of two parts, whereby “A” stands for the active part and “P” for the passive part. In the active part, the sender and receiver unit are integrated in one compact standard housing. The cable-free passive part – the deflection unit – reduces the effort needed for cabling and installation to a minimum, therefore increasing cost efficiency. The passive side with the scepter design is particularly innovative. It can be used to achieve a scanning range of up to 8 m by deflecting the light beam of the sender unit and guiding it back to the receiver unit using prisms.

The deTem Core A/P is the especially economical variant for simple access protection up to 8 m.

The deTem4 A/P is impressive in its flexibility and intelligence: it ensures safe access and an uninterrupted material flow with 2-signal muting. With IO-Link, data can be read out in real time.

Install, connect, get started – the deTem4 LT Muting A/P is the plug and play solution for safe human-material differentiation for automated pallet conveyor systems.

Low installation effort and customized to your application

For specific environments: special deTem variants

For specific environments: special deTem variants

The requirements on multiple light beam safety devices are different depending on the industry. For example, they have to comply with hygiene standards in food production and processing. In explosion-hazardous areas, on the other hand, multiple light beam safety devices must comply with explosion protection standards, for example regarding very high resistance. For this reason, SICK has developed various deTem variants that meet the respective requirements of different industries, but always offer you maximum flexibility and productivity.

Access protection for areas with high hygiene standards is provided by the IP69K variants: the housings of the photoelectric sensors are easy to clean and are made of food-friendly plastic and stainless steel

For Zone 1 and 21: deTem4 Core Ex in a fully assembled and pressure-resistant, explosion-proof enclosure (Ex II 2GD)

For Zone 2 and 22: deTem variants Ex II 3GD with special mechanical resilience

For the individual requirements of your industry: reliable protection for specific environments