The UPC 1000 is a low-temperature dehumidifier designed for precise and efficient batching treatment. It excels in moisture removal while preserving material integrity, making it ideal for industries like pharmaceuticals, food processing, and chemical manufacturing. With robust construction and advanced technology, it ensures reliable performance, energy efficiency, and consistent quality in production.

| Maintenance Task | Frequency | |||

| bi - batch | Monthly | Quaterly | Yearly | |

| Air Intake Filter Washable | X | |||

| Compressor Checks : | ||||

| Pressure Gauge | X | |||

| Crankcase Heater (if required) | X | |||

| Lugs and cable connections | X | |||

| Pressure Switches - Set Point, Check Pressure HP & LP (at same time) | X | |||

| Overload Protection Operaation | X | |||

| Amps & Voltage | X | |||

| Vibration or Grommet Support | X | |||

| Refrigerant Circuit Checks : | ||||

| Charge and leaks (if needed) | X | |||

| Filter Drier | X | |||

| TXV Functioning (if needed) | X | |||

| Pipe insulation | X | |||

| Electrical Component Checks : | ||||

| General Inspection for loose connection | X | |||

| Check Thermostat Operation | X | |||

| Check Control Panel Operation and Outputs | X | |||

| Check Volts and Amps for imbalance | X | |||

| Check Overheating of motors | X | |||

| Blower Belting | X | |||

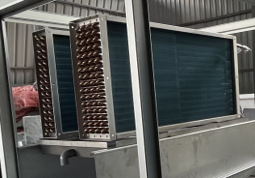

| Coils : | ||||

| Condensar, Cooling and Heating - Clean with water only |

X | |||

| Cabinet Checks : | ||||

| Inspect and clean rust | X | |||

| Tighten loose screws | X | |||

| Fault | Possible Causes | Solution |

| Compressor does not run | Power failure | Check the power supply |

| Shut down by protection device | Check and determine the causes | |

| Drying time reach set point | Check the control setting time | |

| Compressor frequent cut in / cut out | Over charged or insufficient refrigerant | Check the amount refrigerant |

| High / Low Pressure Switch | Manual reset - Push Green Button | |

| Unsufficient Refrigerant Charge | Refrigerant leak at the system | |

| Compressor Noisy | Power failure or wrong phase sequence | Check the power supply |

| Refrigerant flow back | Check Expansion Device superheat and valve opening position | |

| Compressor internal Problem | Replace Compressor | |

| Insufficient Heating-Supply Air | Insufficient Refrigerant | Check unit for leaks. Add refrigerant for the system |

| Wrong expansion device setting | Check Expansion Device superheat and valve opening position. Replace it if necessary | |

| Filter Drier Choked | Replace filter drier | |

| Suction Tube Freezer | Air flow rate choked / slow | Clean air intake filter, sludge bucket air hole block or sludge too lumpy |

| Discharge Pressure Too High | Refrigerant over-charged | Remove the excess refrigerant |

| External fan faulty / tripped | Check fan motor ohm and shorting issue. Replace it if necessary | |

| Discharge Pressure Too Low | Insufficient Refrigerant | Check unit for leaks. Add refrigerant for the system |

| Insufficient air flow to cooling coil | Clean air intake filter, sludge bucket air hole block or sludge too lumpy | |

| Wrong expansion device setting | Check expansion valve device superheat and opening position. Replace it if necessary | |

| Blower Motor does not run | Power failure | Check the wiring |

| Motor malfunction | Replace the motor or repair |