详情

PLM-B Desktop Round Bottle Labelling Machine

-

Introducing our Labelling Machine: the epitome of efficiency for all your packaging needs. Versatile, precise, and easy to operate, it's the ultimate solution for industries nationwide. Available via Obsnap, our trusted Penang supplier, serving Malaysia with unparalleled quality and speed. Upgrade your packaging process today !

What is a labeling machine ?

labeling machine is a label machine that dispenses or applies labels on different containers, items, packages, or products. Through coordination of the different components, a labeling machine can print these labels onto the desired product.Labeling Machines Have High Performance And Are Cost-effective

Labelling Machine Indroduction :

- Suit for round bottle in different sizes;

- Can operation alone or connect with production line;

- With auto feeder turntable and collection turntable for optional;

- Machine can customized;

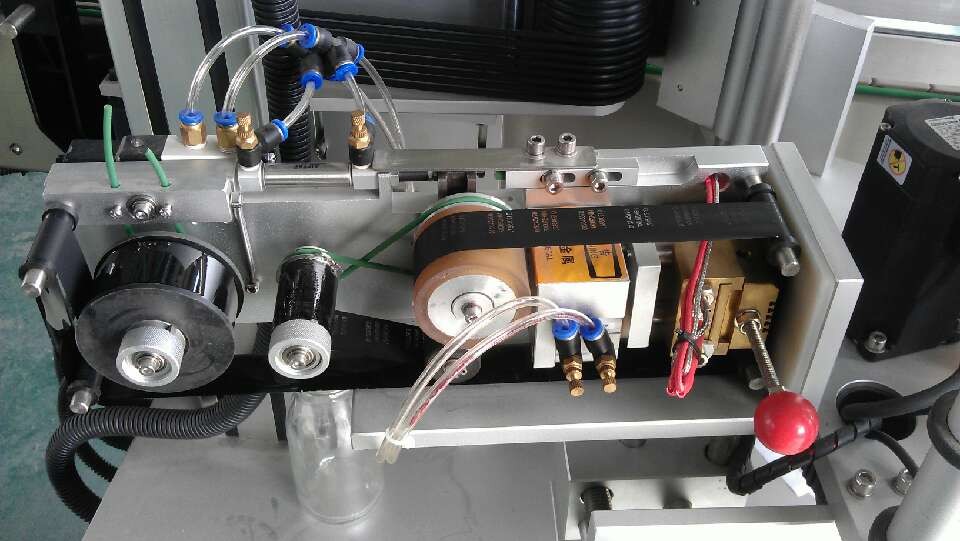

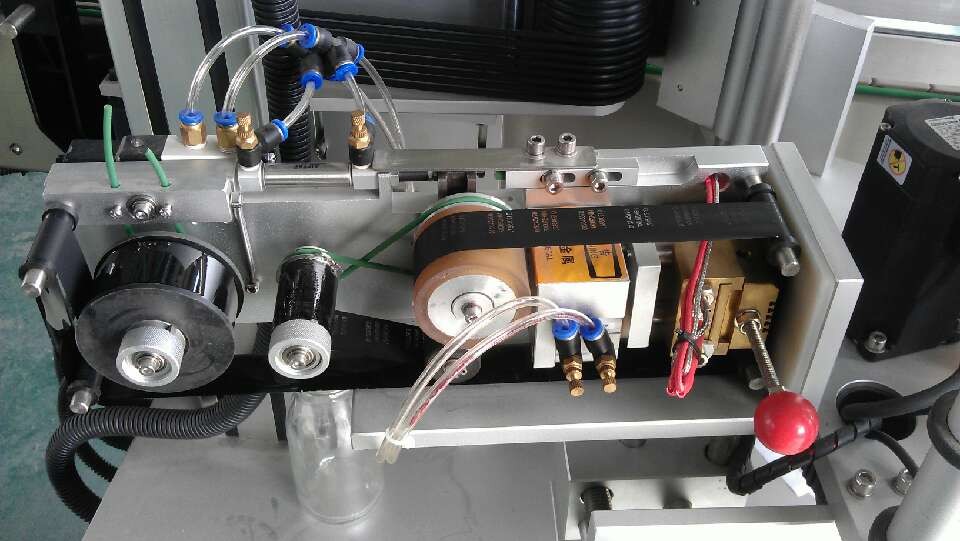

Labelling Machine Equipment Composition :

Electrical cabinet, Conveyor, Roll label device, Brush label device, 1# labeling engine, Operation system and control system.

Labelling Machine Equipment Function Characteristics :

- Control system: Delta PLC control system, with high stable operation and extremely low failure rate.

- Operation system: MCGS Touch Screen, with Chinese and English language, rich with help function and fault display function,easy operation.

- Check system: Korea Automatic check label and bottle sensor, Desktop check label position, stable and convenient don’t have much higher requirement for the worker skill.

- Alarm function : such as label spill, label broken or other malfunction during machineworking all will alarm and stop working.

- Machine Material:The machine and all spare parts all use stainless steel 304 and use oxidizing treatment the machine surface, it will more durable and have longer life even in the Wet environment.

.jpg)

Printer Device Printing Effect

Labelling Machine Working Process :

- Worker put bottle on conveyor and delivery to labeling engine one by one.

- When sensor check bottle, send signal to PLC, PLC received the signal deal with information first, then output signal to servo motor driver, driven by the drive motor send label.

- The brush label device past label on bottle one side first, then bottle rolling

around in the roll label device, brush label on bottle body for around, labeling finish.

Nowadays, walk-through Labelling Machine are used on a daily basis for a variety of purposes. They are frequently utilised in food industry and more. Do you need additional guidance or choices? If you're looking for the top walk-through Labelling Machine supplier in Malaysia, Obsnap Penang is the perfect option.

We are a Labelling Machine supplier based in Malaysia. If you're interested in our products, feel free to contact us via WhatsApp or email for inquiries.

更多 Obsnap Instruments (Penang) Sdn. Bhd. 相关资料

.jpg)