The Agilent TwisTorr 304 FS turbomolecular high-vacuum pump combines Twistorr drag stage technology and Agilent Floating Suspension to provide high performance, reliability and economy. TwisTorr drag stages create high compression ratios for light gases such as Hydrogen and Helium to deliver high throughput and high tolerance of foreline pressure, thereby permitting the use of smaller and more economical backing pumps. This technology results in a compact rotor design that is energy-efficient and maintains a low operating temperature. The Agilent Floating Suspension system reduces noise and vibration, and ensures optimal bearing operating conditions to extent operating life, minimize system downtime, and assure stable pumping performance over time. The unique bearing and dry lubrication in the TwisTorr 304 FS eliminate oil and maintenance, and permit operation of the pump in any orientation. Available with on-board or rack controllers.

| Pumping speed | ISO 100 / CF 6” | ISO 160 / CF 8” |

| N2 | 250 l/s | 250 l/s |

| He | 255 l/s | 255 l/s |

| H2 | 220 l/s | 220 l/s |

| Ar | 250 l/s | 250 l/s |

| Gas throughput at full rotational speed(with recommended forepump) |

Ambient Temp. (25°C) |

Water Temp. (25°C, 50 l/h) |

| N2 | 170 sccm | 170 sccm |

| Ar | 110 sccm | 110 sccm |

| Compression ratio & Foreline Tolerance | ||

| N2 | > 1 x 1011 | >10 mbar |

| He | > 1 x 108 | >10 mbar |

| H2 | 1.5 x 106 | >4 mbar |

| Ar | > 1 x 1011 | >10 mbar |

| Base pressure with recommended forepump (5 m3/h) | < 1 x 10-10 mbar (< 1 x 10-10 Torr) | |

| Inlet flange | CFF 8” O.D. ISO 160 | |

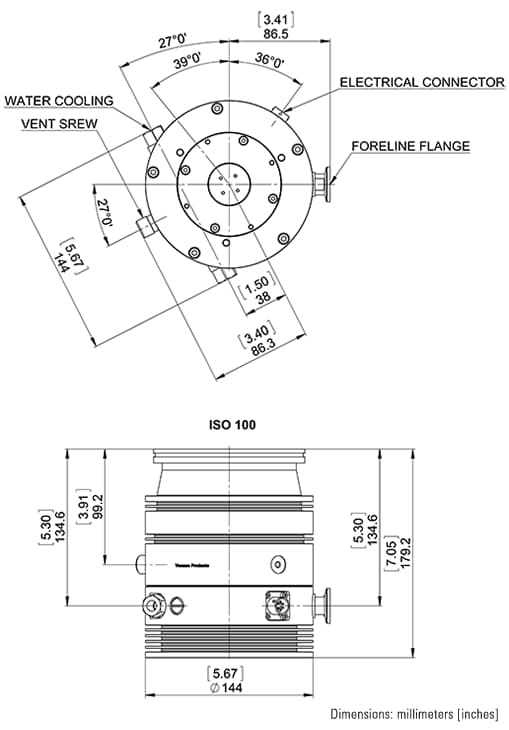

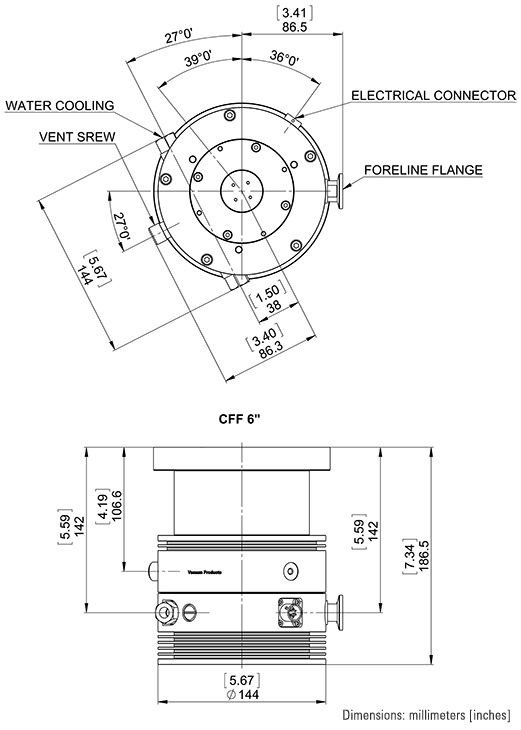

| CFF 6” O.D. ISO 100 | ||

| Foreline flange | KF16 NW (KF25 - optional) | |

| Rotational speed | 60000 rpm (1010 Hz driving frequency) | |

| Start-up time | < 3 minutes | |

| Recommended forepump | mechanical: | Agilent DS 102 |

| dry pump: | Agilent SH 110 | |

| Operating position | Any | |

| Operating ambient temperature | +5 °C to +35 °C | |

| Relative humidity of air | 0 - 90 % (not condensing) | |

| Bakeout temperature | 80 °C at inlet flange max (ISO flange) | |

| 120 °C at inlet flange max (CFF flange) | ||

| Lubricant | Permanent lubrication | |

| Cooling requirements | Forced air (5- 35 °C ambient temperature) | |

| Water (mandatory if ambient temperature > 35 °C) | ||

| Coolant water | Minimum flow: 50 l/h (0.89 GPM) | |

| Temperature: +15 °C to +30 °C | ||

| Pressure: 3 to 5 bar (45 to 75 psi) | ||

| Noise Pressure level | < 50 dB(A) at 1 meter | |

| Storage temperature | -40° C to +70° C | |

| Max altitude | 3000 m | |

| Weight kg (lbs) | Pump ISO 100 | 5.5 kg (12.3) |

| Pump CFF 6’’ | 7.5 kg (16.5) | |

| Pump ISO 160 | 5.7 kg (12.6) | |

| Pump CFF 8’’ | 9.7 kg (20.9) | |

|

Malaysia

Malaysia