Extensive Experience: With many years in the industry, we have rich expertise and professional knowledge to help you get the most suitable machine with the right configuration, avoiding potential mistakes and troubles that other factories, lacking such experience, may cause.

Superior Arc Height Adjustment System: Our plasma cutting machine uses a highly sensitive automatic arc height adjust system that sends out 12,000 signals per minute, compared to the standard 10,000 from other systems. This results in better cutting quality and slightly faster cutting speed using the same power plasma source.

Effective Smoke Extraction: Equipped with two fans for optimal smoke extraction, the front fan blows air to the back while the rear fan exhausts the smoke outside, ensuring a cleaner working environment. In contrast, other factories often provide only one fan or none at all.

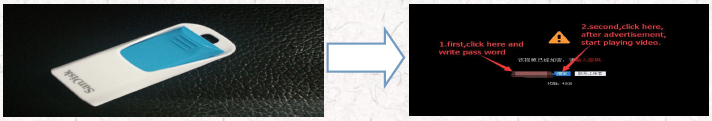

Thorough Quality Checks and Support: All machines undergo three quality checks before shipping. Each machine comes with an 8GB flash drive containing instructional videos to help customers quickly learn how to operate the machine and start making a profit. We also offer an online video platform for after-sales service, while smaller factories may lack such comprehensive support.

Anti-Rust Paint Treatment: Our machines receive professional anti-rust treatment, with two layers of anti-rust paint followed by color coating to ensure long-term protection from rust. Other manufacturers may only apply one coat of rust protection or skip it entirely, leading to quicker deterioration.

Extended Warranty: Due to our use of high-quality components and rigorous testing, we offer a 2-year warranty on our machines, compared to the typical 1-year warranty from other factories.

Free Design Software: We provide a 2GB processing design package (valued at USD 320) and professional metal cutting software, including thousands of beautiful designs. This allows customers to immediately start working without needing an engineer to assist with design.

Sturdy Machine Structure: Our machine is designed by a renowned mechanical professor and includes additional support columns to withstand the weight of large, thick metal sheets without deforming. Smaller factories often skip these reinforcements to save costs, resulting in machines that may deform under heavy loads.

| Model | OLT-PD-1530 120A |

| X,Y working area | 1500 × 3000mm |

| Z working area | 150mm |

| Body dimension | 2200mm × 3600mm × 1450mm |

| Packing dimension | 2400mm × 3900mm × 1550mm |

| Lathe bed | Very thick steel structure |

| Machine Power | 8.5kw |

| Voltage | 220V/415V |

| Reposition precision | 0.05mm |

| Processing precision | 0.5mm |

| Maximum cutting speed | 12000mm/min |

| Torch Height control mode | Automatic |

| Cutting thickness 120A | Max 25mm carbon steel,the most often 18mm |

| Plasma power supply | 120A |

| Control system | STARfire |

| Motors | Stepper motor |

| Software | Starcam |

| Weight | 1800KGS |

| Plasma Air Pressure | Max.0.8Mpa |

| Working Temperature | -10°C-60°C. Relative Humidity, 0-95% |

| LCD Display Dimension | 7 Inches |

Malaysia

Malaysia