Introduction

One of Bentsai's main areas of expertise is the research, design, development of manufacturing processes, and industrial application of thermal inkjet printheads that utilize microfluidics MEMS technology. Bentsai places a strong emphasis on the research and development of cutting-edge thermal printhead chips while continuously advancing their technological capabilities. At the same time, Bentsai is dedicated to collaborating with thermal inkjet printer developers for industrial applications, thereby contributing to the growth and progress of the industry.

Customization Solutions

We offer customized TIJ thermal inkjet printheads for office inkjet printers, industrial inkjet printers, and inkjet printers for specialized industries. The printhead can be tailored to the user's requirements, including nozzle size, nozzle arrangement, and more, to ensure a high-quality and clear printing result. Customized customers have the flexibility to personalize the performance and parameters of the ink cartridge based on their specific needs and printing requirements. Additionally, customers can adjust ink color, capacity, and other characteristics to meet various printing needs.

Interested in our customization service for thermal inkjet printheads? Please send an email to [email protected] immediately to let us know your requirements and to learn more about the further information.

Technology Introduction

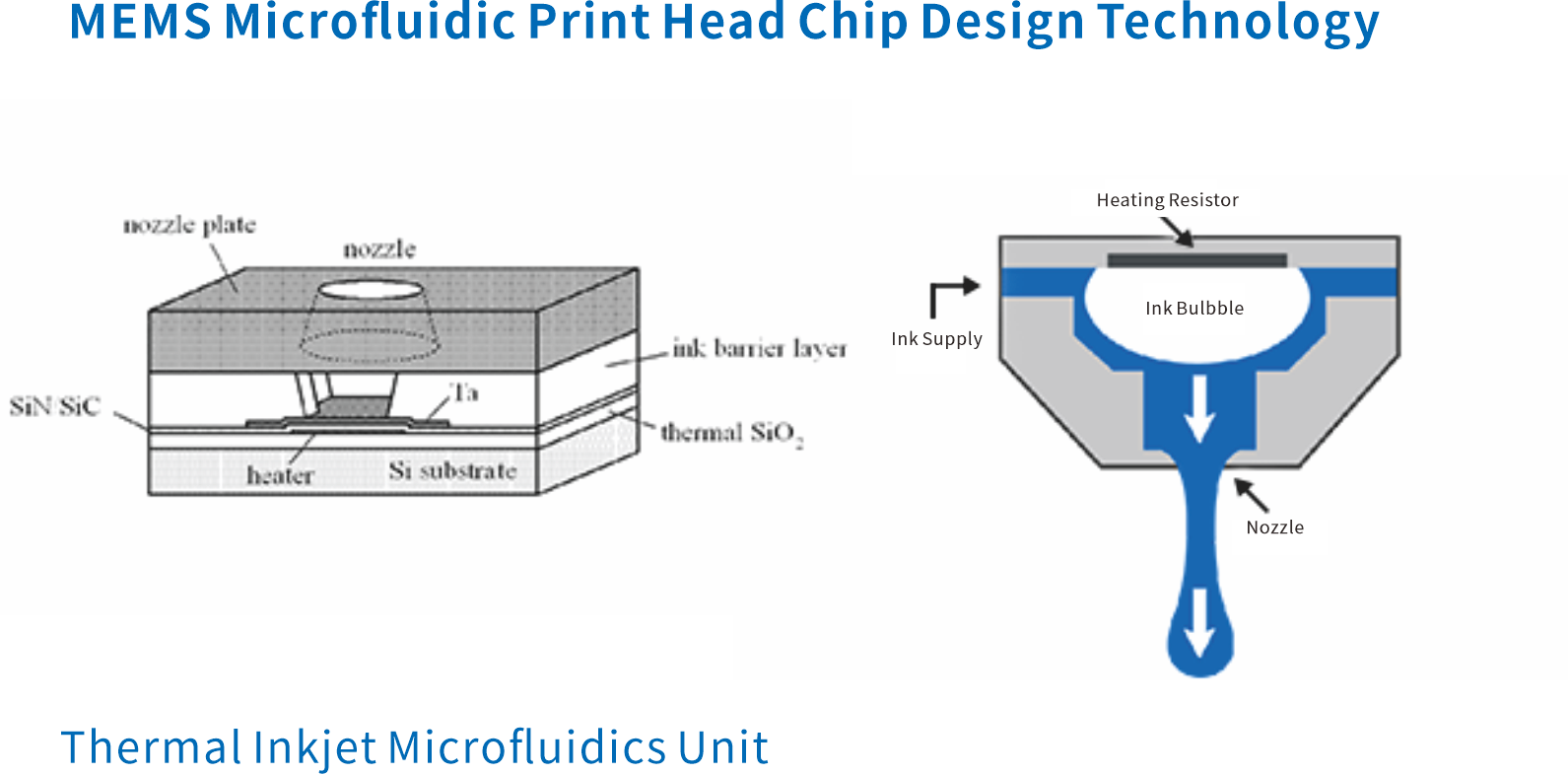

Bentsai printheads utilize drop-on-demand thermal inkjet technology based on MEMS . This enables us to utilize semiconductor microfabrication techniques to etch microfluidic structures onto chip surfaces. These microfluidic structures are integrated and encapsulated to form a multifunctional microfluidic chip. By controlling the chip, we can utilize multiple pulse signals to achieve precise microfluidic jetting. This results in high-speed, uniform, and reliable printing, with a long lifespan and low cost.

Technology Introduction

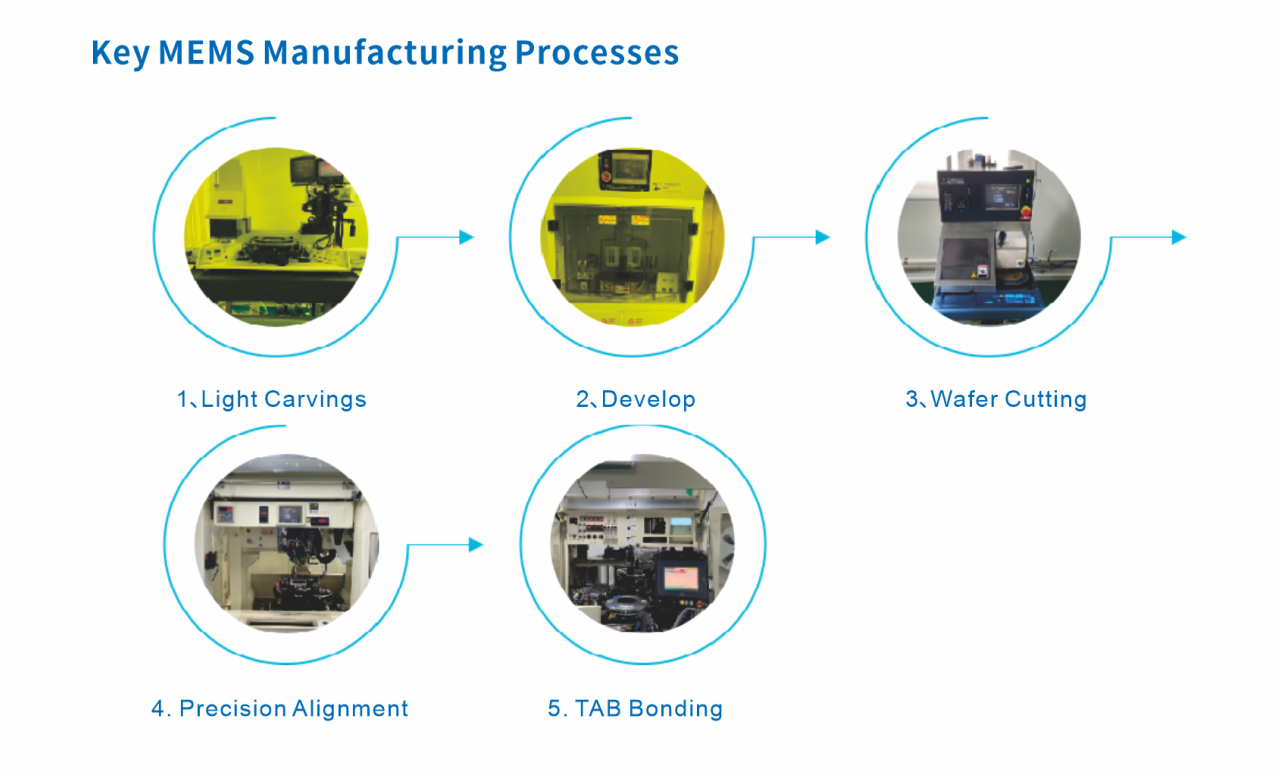

Bentsai has developed and imported more than 90 sets of high-precision equipments and has successfully built a MEMS production line for thermal inkjet printhead chips, covering the entire process from wafer design to finished inkjet printheads manufacturing. Inkjet printheads are classified as high-end semiconductor equipment in the manufacturing industry, known for their high precision and cost. Bentsai team has achieved a significant breakthrough in microfluidic MEMS process technology, reducing the costs inkjet printing equipment developers.

|

Datasheet for TIJ Printhead Customization |

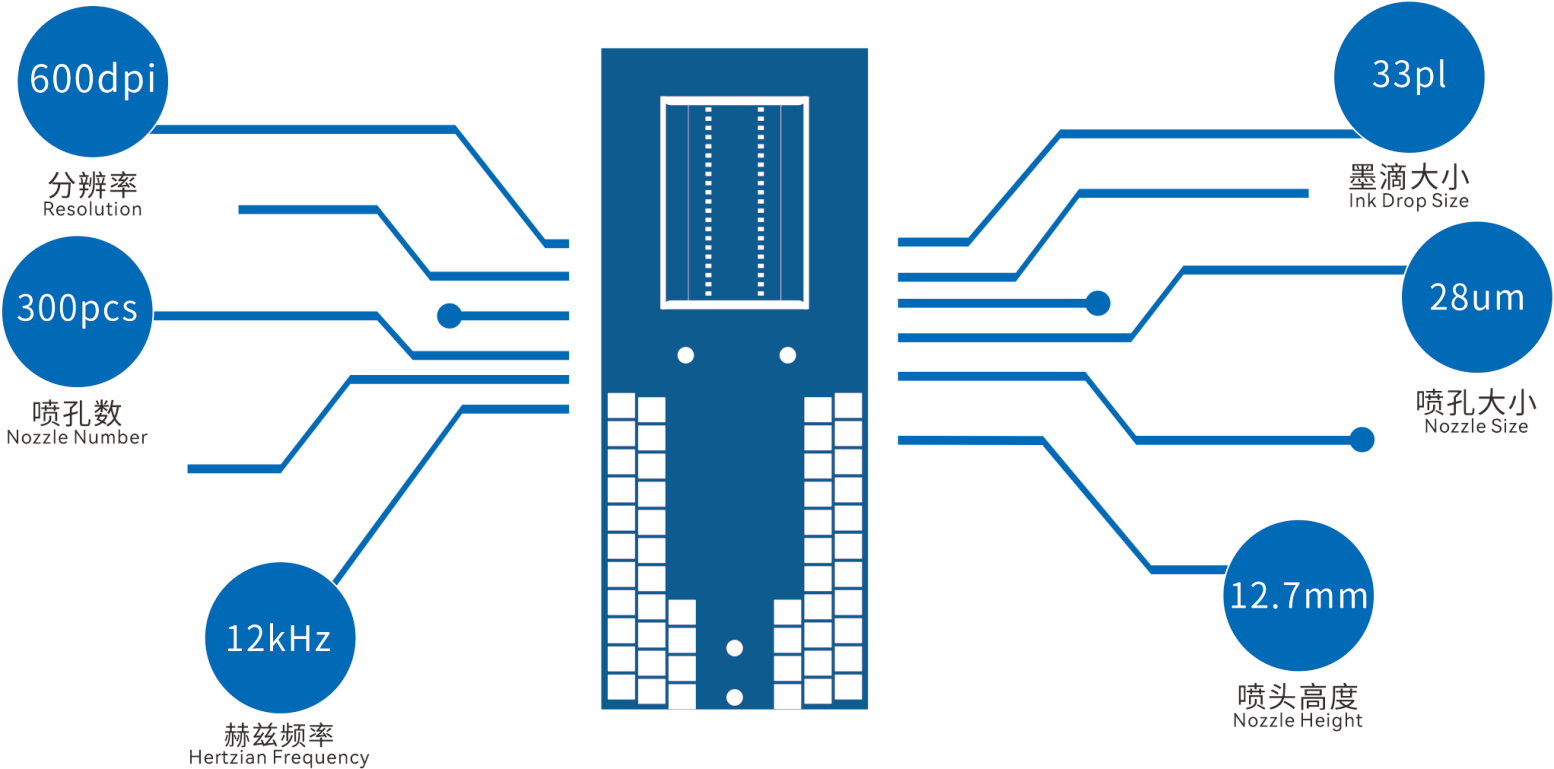

| Specifications | Description | Standard | Customized |

| Product Model | BC800 | Definable | |

| Color | Mono | C/M/Y/K | |

| Nozzle Numbers | Nozzle Numbers*Nozzle Rows*Color Numbers | 150*2*1 | 300*2*4 Defined by specification sheet |

| PADs | Number of Contacting Pads | 52 | Defined by specification sheet |

| Resolution (DPI) | Single Row Resolution* Number of Rows | 300*2 | 75DPI-1200DPI |

| Nozzle Spacing (um) | Distance Between Nozzles | 84.6 | 42.3 (Minimum) |

| Nozzle Diameter (um) | Nozzle Diameter | 28 | 9~30 |

| Ink Droplet Size (pl) | Single Inkdroplet Size | 33 | Defined by specification sheet |

| Print Height (mm) | Max. Print Height | 12.7 | 8~25.4 |

| Chip Lengt (mm) | 15.1 | Defined by specification sheet | |

| Chip Width (mm) | 6.9 | Defined by specification sheet | |

| Printhead Dimension (mm) | Printhead Size (including flexible cable) | 60*17 | Defined by specification sheet |

| Cartridge Size L*W*H (mm) | 92*70*19.3 | Defined by specification sheet | |

| Ink Weight(g) | 68 | Defined by specification sheet | |

| Ink Volume(ml) | Ink Capacity | 42 | Defined by specification sheet |

| Ink Throw Distance(mm) | Distance between print nozzles and object | <5mm | <5mm |

| Ink Container | Ink bag | Ink bag/Sponge | |

| Ink Compatibility |

Water based Solvent |

Water based Solvent |

|

| Voltage and Pulse(V/us) | Voltage should match the ink type |

Solvent:Votage 9.3V Pulse:2.0us Water based:11.8V Pluse: 2.0us |

9V~12V 2.0us~2.2us |

| Ink Jetting Frequency ( single nozzle) | 15~18KHZ | 15~18KHZ |

|

Printing Capacity of water based ink cartridge ( varies on printer parameters setting) |

| Working Temperature & Humidity |

Best 5°C -to 35°C Humidty10%-80%RH |

Best 5°C -to 35°C Humidty10%-80%RH |

|

| Storage Temperature & Humidity |

Temperature-40°C - 60°C Humidity10%-80%RH |

Temperature-40°C - 60°C Humidity10%-80%RH |

|

| Standard Printing Speed (ISO)ppm | 14 ppm | 14 ppm | |

| Ppm | 16 ppm | 16 ppm | |

| Test Method(A4 5% Coverage) | Approximately 930 pages | Approximately 930 pages |

Indonesia

Indonesia