Area of Application

Laser Cutting

.jpg)

CO2 Laser Cutting

CO2 (carbon dioxide) lasers are commonly used for cutting a wide range of materials, including metals, plastics, woods, textiles, and more. They operate in the mid-infrared wavelength and are particularly effective for non-metallic materials.

Fiber Laser Cutting

Fiber lasers are primarily used for cutting metals, especially reflective metals like stainless steel and aluminium. They use a fiber-optic delivery system to deliver the laser beam, which enhances the quality and efficiency of the cutting process. Fiber lasers are known for their high cutting speed and energy efficiency.

CO2 Laser Marking

CO2 lasers are commonly used for marking non-metallic materials such as wood, glass, ceramics, plastics, and certain types of organic materials. They produce high-quality, precise markings without causing significant heat damage to the material.

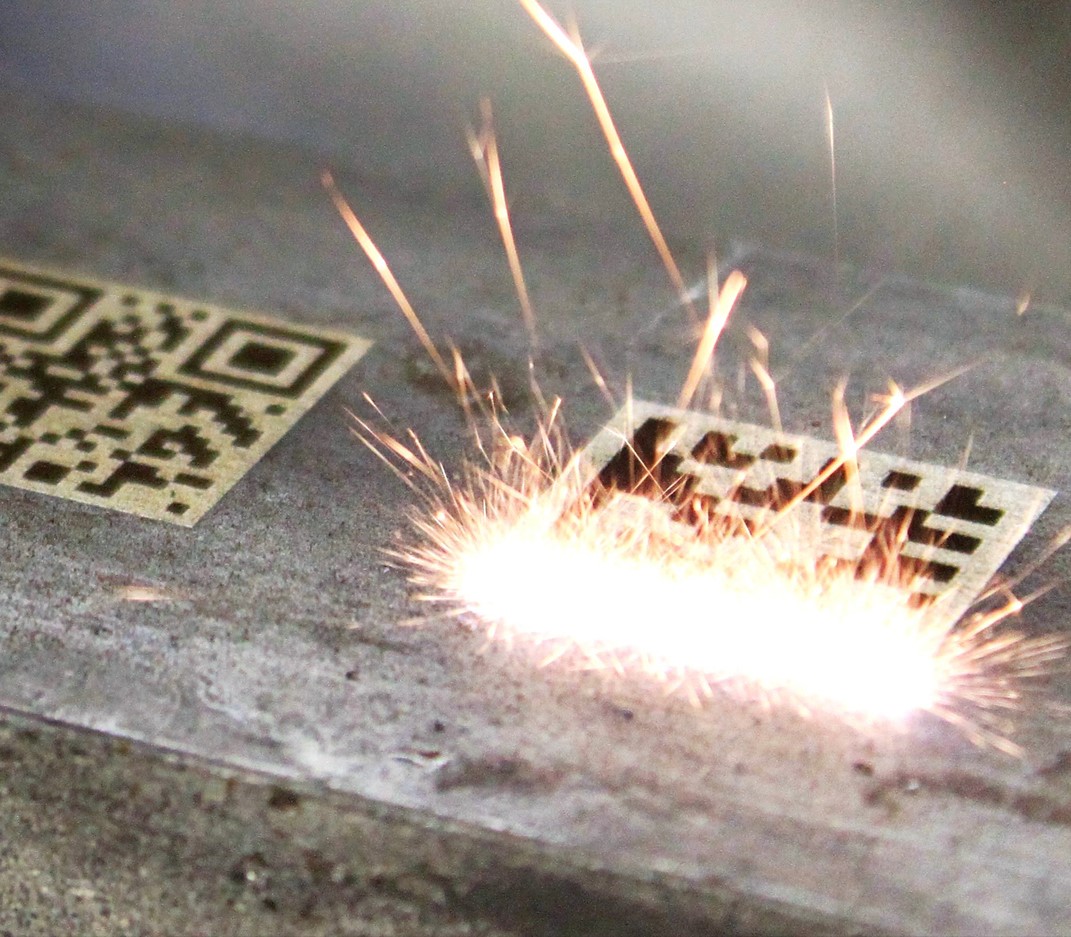

Fiber Laser Marking

Fiber lasers are widely used for marking a variety of materials, including metals (stainless steel, aluminum, etc.), plastics, ceramics, and more. They are known for their high marking speed, fine detail capability, and durability. Fiber lasers are a popular choice for industrial applications like product traceability and branding.

Indonesia

Indonesia