At PCA Steel Engineering Sdn Bhd, we offer Advanced CNC Machining & Quality Control Services designed to meet the diverse needs of the manufacturing industry. Our commitment to precision, quality, and innovation sets us apart as a leader in the CNC machining sector.

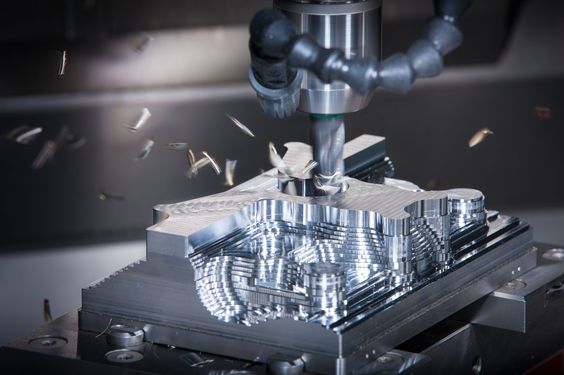

State-of-the-Art Technology: Utilizing the latest CNC technology, we ensure high precision and efficiency in the machining process. Our advanced machinery is capable of producing intricate parts with tight tolerances, meeting the demands of various industries, including automotive, aerospace, and industrial applications.

Custom Machining Solutions: We understand that every project is unique. Our team of experienced engineers works closely with you to develop tailored machining solutions that meet your specific requirements. Whether it's small-scale prototypes or large production runs, we have the capability to deliver high-quality results on time.

Material Versatility: Our CNC machining services can accommodate a wide range of materials, including metals, plastics, and composites. This versatility allows us to cater to various industries, ensuring that we can handle your specific material needs with expertise.

Rigorous Quality Assurance: Quality is our top priority. Our dedicated quality control team employs rigorous inspection processes at every stage of production to ensure that all components meet stringent industry standards. We utilize advanced measuring equipment to verify dimensions and tolerances, ensuring complete accuracy.

ISO Certified Processes: PCA Steel Engineering Sdn Bhd adheres to international quality standards, including ISO 9001, to guarantee that our processes and products consistently meet customer expectations and industry regulations. Our commitment to quality is reflected in every part we produce.

Detailed Documentation: We provide comprehensive quality control documentation, including inspection reports and certifications, ensuring transparency and accountability throughout the production process.

Increased Efficiency: Our advanced CNC machining technology reduces lead times and enhances production efficiency, allowing you to bring your products to market faster.

Cost-Effective Solutions: By leveraging our state-of-the-art machinery and skilled workforce, we offer cost-effective machining solutions that do not compromise on quality.

Expert Support: Our knowledgeable team is here to provide guidance and support throughout your project, ensuring you receive the best possible outcomes.

We utilize advanced CNC milling technology to achieve precise and intricate machining of steel components. Our capabilities ensure high accuracy, complex geometries, and superior surface finishes for various applications.

Our CNC turning services deliver exact dimensions and tolerances for steel parts, leveraging cutting-edge machinery to produce smooth, accurate, and reliable components with efficient turnaround times.

Our comprehensive QC inspection process ensures that all machined components meet stringent quality and industry standards. We use state-of-the-art equipment and techniques to inspect and validate each part, guaranteeing optimal performance and compliance.