GRANITE TABLE TOP

.png) Granite Table Top

Granite Table Top

natural stones that cut from quarries. All the composition of granite is different around the world. It has unique colors and patterns with high polish finish.

- MADE OF PURE, SOLID STONE AND ITS IS A NATURAL STONE , GRANITE COUNTER TOP IS ONE OF THE MOST COMMON AND PREFERRED COUNTERTOP MATERIALS BECAUSE ITS SOLID, DURABLE AND LONG LASTING.

- EXPECT GRANITE TABLE TOP TO BE VERY HEAT-RESISTANT, UP TO TEMPERATURES HOTTER THAN YOUR STOVE. HOWEEVER,THAT DOESN’T MEAN YOU SHOULD PLACE HOT PANS STRAIGHT FROM THE STOVE AND ONTO THE COUNTER TOP WITHOUT TRIVET.

PROS

- Resistance against heat

- Scratch resistant

- Selection of colors & patterns

- Suitable for heavy cooking

- Thickness of granite 30mm

CONS

- Porous Surface

- Grain cannot be control

SPECIAL FEATURES

- COLOR COMES IN A WIDE RANGE OF COLORS INCLUDING BLACK, GRAY ,BLUE

- TEXTURE IS USUALLY COARSE-GRAINED AND GRANULAR WITH VISIBLE MINERAL GRAINS

- LOW POROSITY WHICH MEANS THAT IT IS RESISITANT TO WATER ABSORBTION

- RESISSTANT TO ACIDS, WHICH MAKE IT IS A GOOD MATERIAL FOR USE IN KITCHEN COUNTER TOPS

- THERMALLY STABLE AND CAN WITHSTAND HIGH TEMPERATURES WITHOUT BREAKING DOWN OR CHANGING COLOR OR TEXTURE.

- GRANITE IS A VERY HARD AND DURABLE MATERIAL ,ITS DIFFICULT TO UNINTENTIONALLY BREAK, SCRATCH OR CRACK

SAMPLE COLORS.

CHERRY PINK

CHERRY PINK

BERRY WHITE

BERRY WHITE

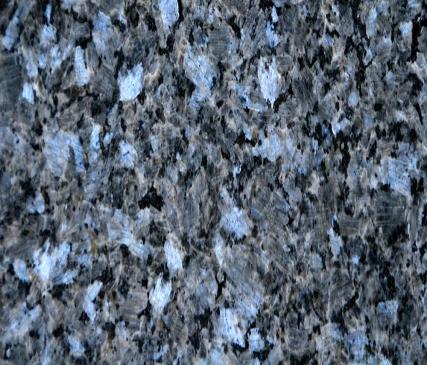

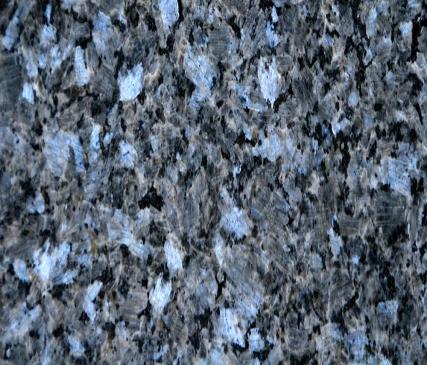

BLUE PEARL

BLUE PEARL

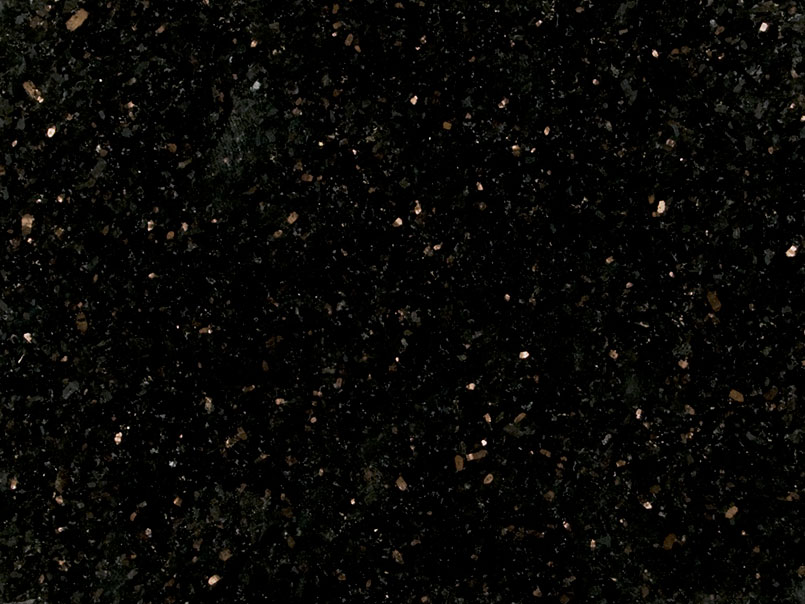

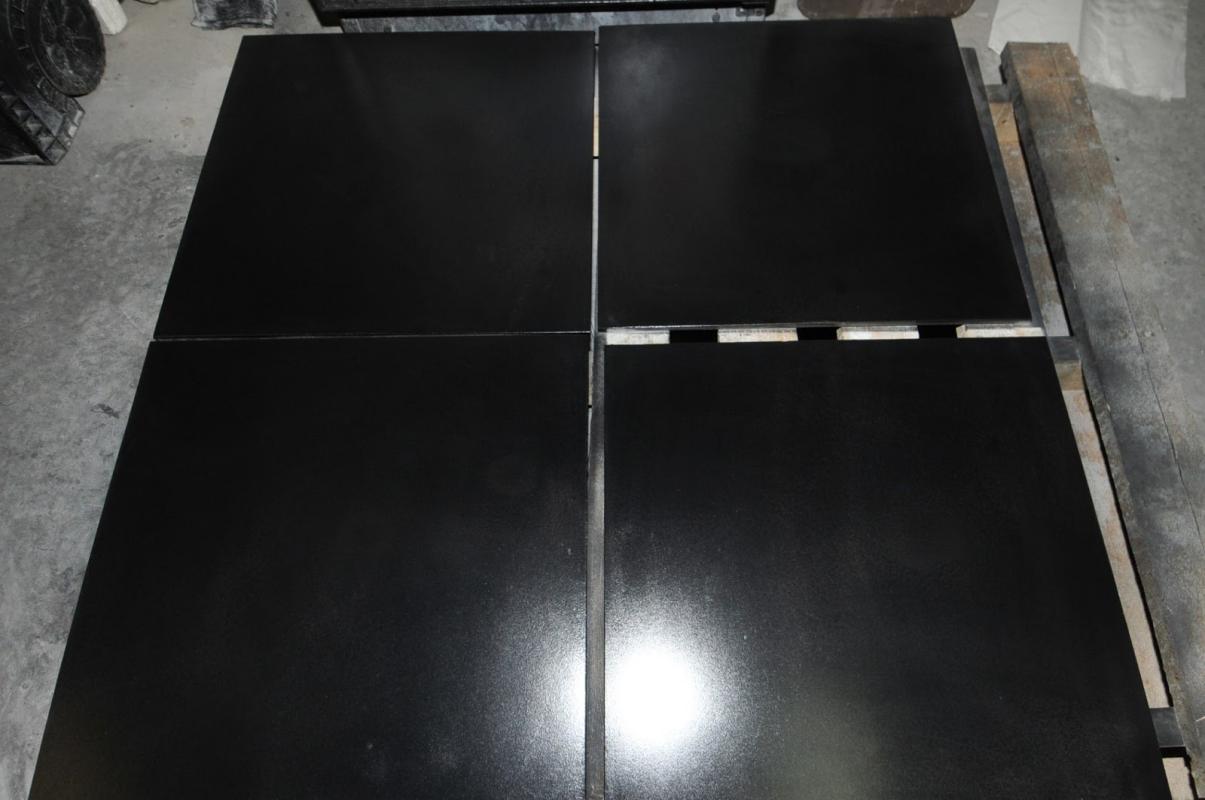

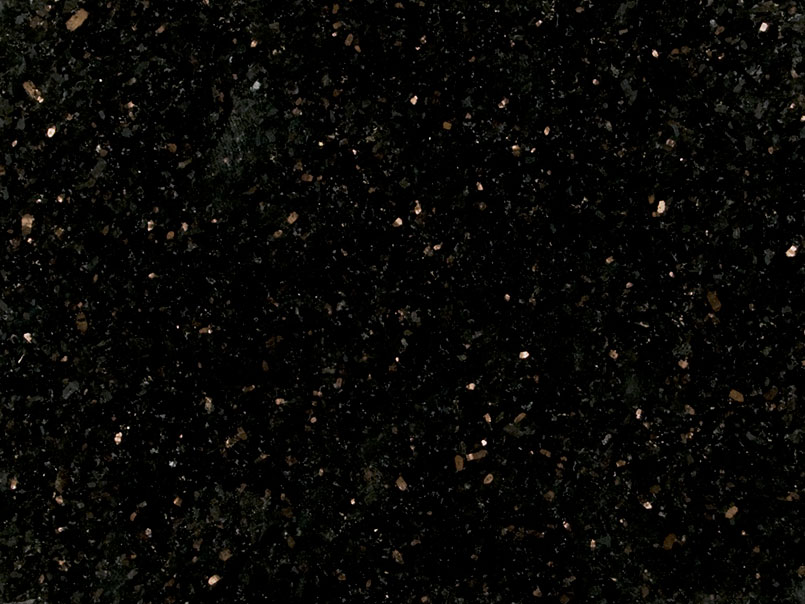

BLACK GALAXY

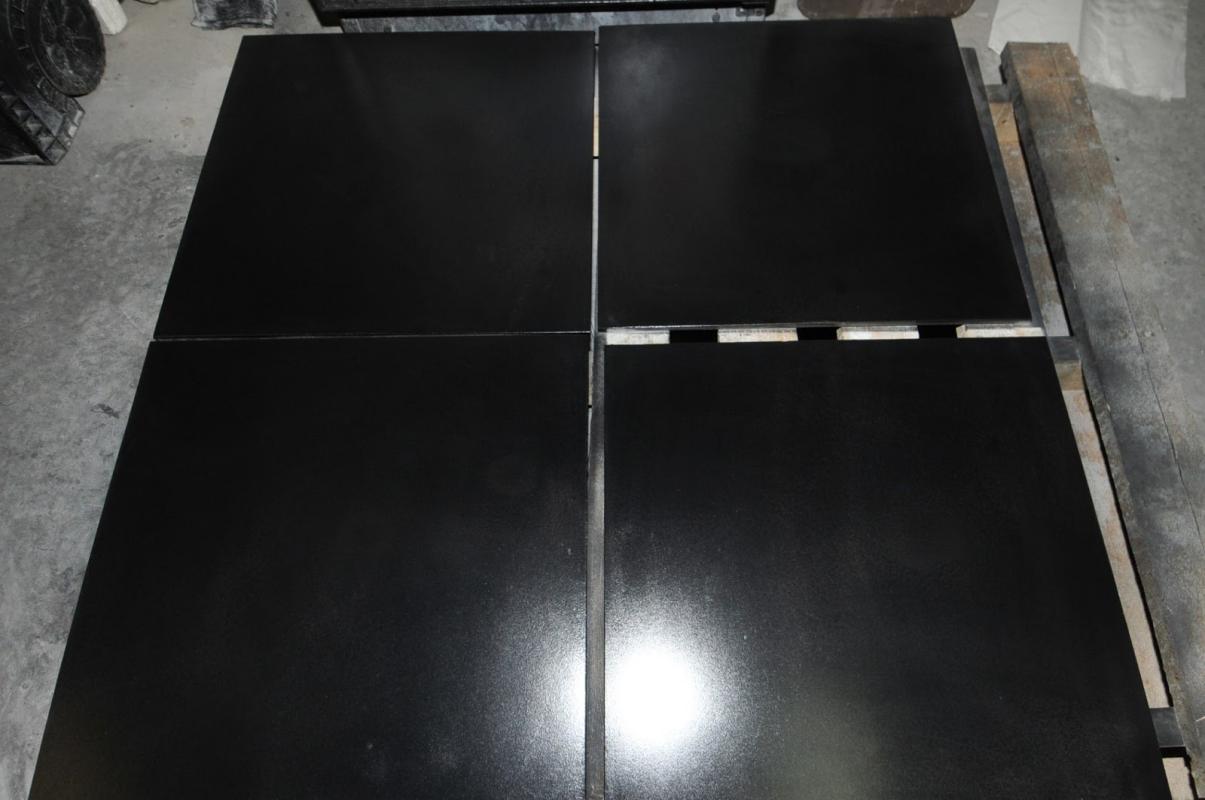

GRANITE FINISHING

BLACK GALAXY

GRANITE FINISHING

COMPRESSED MARBLE

COMPRESSED MARBLE

COMPRESSED MARBLE IS A TYPE OF ARTIFICIAL STONE COMBINES THE ELEGENT SMOOTH FEEL OF MARBLE WITH RICHER MARBLE PATTERNS. SINCE ITS MAJOR CONSTITUENTS ARE THE BY-PRODUCTS OF MARBLE MINING AND PROCESSING INDUSTRIES, IT IS REGARDED AS ONE OF THE ECO-FRIENDLIEST ARCHITECTURAL DESIGNING MATERIALS

COMPRESSED MARBLE IS A TYPE OF ARTIFICIAL STONE COMBINES THE ELEGENT SMOOTH FEEL OF MARBLE WITH RICHER MARBLE PATTERNS. SINCE ITS MAJOR CONSTITUENTS ARE THE BY-PRODUCTS OF MARBLE MINING AND PROCESSING INDUSTRIES, IT IS REGARDED AS ONE OF THE ECO-FRIENDLIEST ARCHITECTURAL DESIGNING MATERIALS

PROS

- Timeless Look

- Natural Material

- Long Lifespan

- Surface Stays Cool

- Simple Clean Up

- Added Design Elements

CONS

- High Maintenance

- Easy to Scratch or Chip

- Stains Easily

SPECIAL FEATURES

1)Myriad of Colour Patterns

Compressed marble, on the contrary, has versatile color and patterns, which enhances selection diversity.

2)Maintenance

Compressed marble, on the other hand, is a non-porous substance that requires lower maintenance and upkeep.

3)Weight

compressed marbles are comparatively slimmer and lighter, thereby enabling portability with ease. Its light-weight makes it easier to install and enhances cost savings.

4)Price

compressed marble is less expensive as it can be easily created in a quarry with a mix of few elements and solidified in a mold.

SAMPLES

COMPRESSED MARBLE FINISHING

COMPRESSED MARBLE FINISHING

QUARTZ STONE

QUARTZ STONE

Quartz stone counter tops are form of engineered stone made from ground-up particles of quartz stone bound together with resins. |

|

Quartz Stone Table Top, is man made table top come with mixing natural stone material.

PROS

- Non-porous and does not require any sealing – ever

- Extremely durable – won’t crack, scratch, or get chipped easily

- Require little to no maintenance, stain-resistant

- Easy to maintain & clean

- High heat resistant

- Suitable for heavy cooking

CONS

- Can discolour over time when exposed to direct sunlight

- Expensive compared to marble

- Susceptible to heat damage

- Can be discolour if exposed to strong chemical

Special features

- Quartz stone has a polished and glossy finishes and it's available with tons of colour choices & styles with many different colors and styles available to choose from.

- more durable and scratch-resistant. It has a non-porous countertop surface so you will never have to worry about permanent stains.

- quartz stone table top is premium, which means that they are more expensive than any other countertop material. But for the price, you’re paying for long-lasting quality.

- Quartz counters are durable and more resistant to scratches, chips and cracks than other surfaces.. Quartz also resists water damage, stains, mold, and bacteria, making it an excellent choice for bathrooms, kitchens, and professional environments.

- With natural stone counter tops like marble and granite, you must use special cleaners and regularly apply a sealant. Quartz counter tops never require sealing

Samples

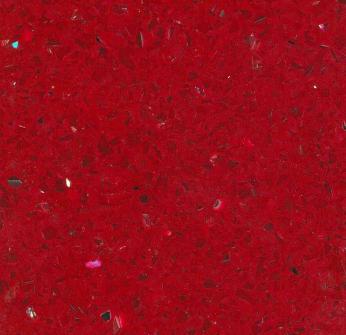

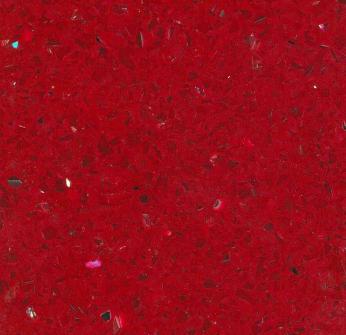

RED QUARTZ

RED QUARTZ

SANDY BEIGE

SANDY BEIGE

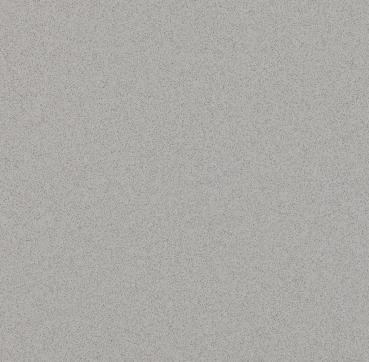

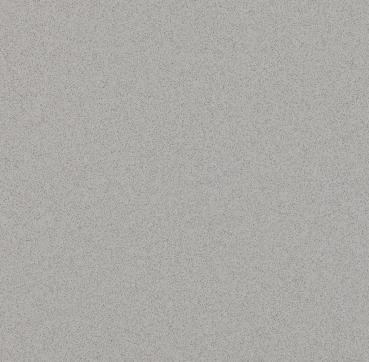

ASH GREY

ASH GREY

BLACK QUARTZ

QUARTZ FINISHING

BLACK QUARTZ

QUARTZ FINISHING

Concrete tiles countertop

Concrete is typically made up of three basic components cement, water, sand. These materials are mixed together to form a paste that hardens over time into a solid structure.

PROS

Concrete is typically made up of three basic components cement, water, sand. These materials are mixed together to form a paste that hardens over time into a solid structure.

PROS

- CUSTOMISABLE

- HEAT AND SCRATCH RESISTANT

- CAN BE CAST INTO COLOR , SHAPE OR PATTERN

CONS

- CAN BE CRACKED AND STAINED

- CAN DISCOLOUR FROM MOISTURE OR WRAP UNDER EXTREME HIGH HEAT

- NEEDS REGULAR RESEALING TO MAINTAIN ITS FINISH, OTHERWISE THE SURFACE WILL BECOME POROUS

SPECIAL FEATURES

- concretes exhibit low thermal properties. Temperature regulation is also made easier in such concretes.

- Corrosion-resistant concretes can be used to safeguard the reinforcements.

- Some concretes have remarkable thermal properties, making them ideal for cold areas.

- Ingredients that are injected into traditional concrete are readily available.

- It can be molded into any shape, just like regular concrete, while retaining special qualities.

- Because particular conditions are maintained in the preparation of special concrete, the construction is more durable than standard concrete.

- Special concretes can withstand harsh environmental conditions and are suitable for extreme weather.

SAMPLES

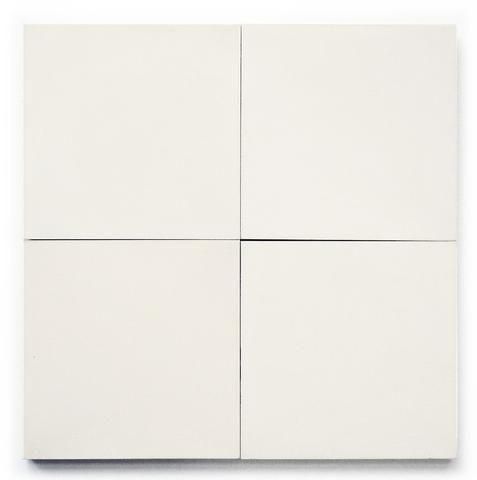

White

White

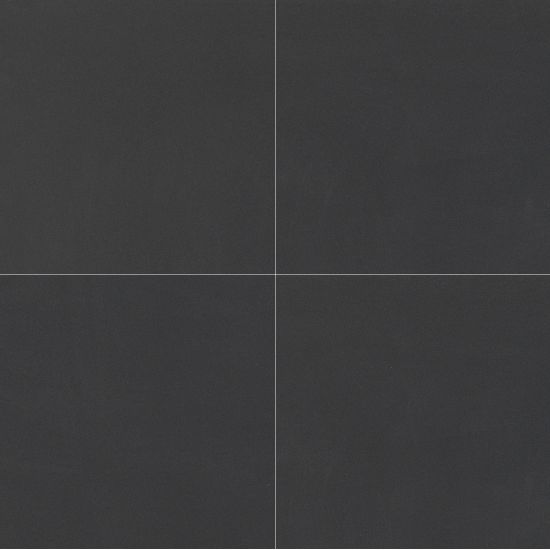

black

CONCRETE FINISHING

black

CONCRETE FINISHING

Laminate countertop (HPL)

.png) HPL TABLE TOP(HIGH PRESSURE LAMINATE, ALSO KNOWN AS FOMECA TOP IS THE DIRECT DESCENDANT OF THE ORIGINAL PLASTIC LAMINATE. HPL LAMINATES IS PRODUCED BY SATURATING MULTIPLE LAYERS OF KRAFT PAPER WITH PHENOLIC RESI.

HPL TABLE TOP(HIGH PRESSURE LAMINATE, ALSO KNOWN AS FOMECA TOP IS THE DIRECT DESCENDANT OF THE ORIGINAL PLASTIC LAMINATE. HPL LAMINATES IS PRODUCED BY SATURATING MULTIPLE LAYERS OF KRAFT PAPER WITH PHENOLIC RESI.

A LAYER OF PRINTED DECOR PAPER IS PLACES ON TOP OF THE KRAFT PAPER BEFORE PRESSING. THE RESULTING IS FUSED TOGETHER UNDER HEAT AND PRESSURE AND CONVERTS THE PAPER SHEETS INTO A SINGLE, RIGID LAMINATED SHEET.

Pros

- Affordable

- Light-weight

- Selection of colors & patterns

- Curved edges

Cons

- Non waterproof

- Non anti-termite

- Surface is easily scratched

Special features

- Thermos-setting creates strong, irreversible bonds that contribute to HPL’s durability.

- Exclusive resistance and steady to physical influences shock and scratch resistance of this material is truly unique.

- Resistance to disinfectant in its standard version is extremely resistant to the active chemical compounds and disinfectants.

- Antibacterial and natural properties due to its anti-static nature, HPL has natural antibacterial properties

- Design features due to the fact that the front layer of the laminate decorative paper forms stylish elements on the design finds a colors, patterns and textures that can be applied to HPL.

SAMPLES

.png)

.png)

.png)

HPL FINISHING

.png)

.png)

Solid surface table top

.png) Solid surface is a synthetic countertop material that contains both minerals and resins. It is a homogeneous, through-body material that feels smooth and silky. It can be buffed to a matte finish or up to a high gloss.

Solid surface is a synthetic countertop material that contains both minerals and resins. It is a homogeneous, through-body material that feels smooth and silky. It can be buffed to a matte finish or up to a high gloss.

Visually, solid surface lacks the depth of natural stone or even quartz. Solid surface does resemble stone far more than laminate does.

The word solid in solid-surface reinforces the idea that this is a stable base, unlike bouncy laminates mounted on medium-density fiberboard.

PROS

- EASY TO REPAIR NON-POROUS TO SPILLS AND STAIN-RESISTANT

- COMES IN VARIOUS COLORS AND DESIGNS

- INVISBLE SEAMS

- EASY MANITENANCE

- CUSTOMISABLE

CONS

- LOWER RESISTANCE TO HARSH CONDITIONS, LIKE CHEMICALS AND HIGH HEAT

- MORE PRONE TO SCRATCHES

- GLOSSY FINISHES CAN REQUIRE HIGH CARE

- MAY SHOW MORE IMPERFECTIONS

- POLLSTER-BASED SURFACES ARE MORE FRAGILE

SPECIAL FEATURES

- Made from thick synthetic acrylic layers and stone-derived materials, solid counter tops offer a great option for a maintenance-free countertop.

- solid surface is easily repairable and fits well in any kitchen design.

- A solid surface countertop can be installed with no visible seams.

- Affordable comparatively valuable for money, especially when you consider the quality and price that you are getting against premium materials like granite, marble and quartz.

- Durable Tough and resistant to both scratches and impacts, solid surface counter tops have a high tensile strength and can easily withstand heavy use

SAMPLE

SOLID SURFACE FINISHING

SOLID SURFACE FINISHING

.png) PORCELAIN

PORCELAIN

.png) Porcelain is a ceramic material made by heating materials,generally including material like kaolin.

Porcelain is a ceramic material made by heating materials,generally including material like kaolin.

The object retains its shape to the kaolin. Impurities such as silica , mineral oxides and feldspar exist in the clay, but rather than detracting from the porcelain quality and coated with pigmented glaze. This is to give them an aesthetic appeal similar to that of natural stone or even marble.

PROS

- Easy maintenance

- High heat resistant

- Durable & scratch resistant

- Easy to maintain & environment friendly

- Low water absorption & UV resistant

- It can make any textures and patterns

Cons

- Low hardness level compare to quartz stone

- Can be costly

- Edge style

Special feature

porcelain is a very lightweight material with several installation options. can get extra-large porcelain slabs manufactured so fewer seams are required. This makes the material a good choice when you want to create a single slab cover look for the entire kitchen island.

Finally, one of porcelain’s biggest pluses is its greenness. It’s a 100% natural product made of raw and clay-based materials, so it’s nice to know you’ll be able to recycle it one day.

Porcelain tiles are known for their high density and low porosity. This means that they are compact and have minimal open spaces between particles. This high density makes them highly durable and resistant to wear and tear, making them suitable for high-traffic areas like floors and counter tops.

- Porcelain tile is translucent

thinner and larger format porcelain tiles may exhibit a slight translucency when held up to light. This can add a subtle visual depth to the tile’s appearance.

- Porcelain tile is good for health

Porcelain tiles are considered good for health and hygiene primarily due to their resistance to moisture. Moisture-resistant tiles are less likely to promote the growth of mold, mildew, and bacteria. This quality is particularly important in environments like bathrooms and kitchens, where maintaining cleanliness is essential.

SAMPLES OF PATTERN

.png)

.png)

.png) Porcelain finishing

Porcelain finishing

.png)

.png)

.png)

CHERRY PINK

CHERRY PINK  BERRY WHITE

BERRY WHITE BLUE PEARL

BLUE PEARL BLACK GALAXY

BLACK GALAXY

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

Malaysia

Malaysia