Plating is very important for lapel pins. The effect of the appearance of the lapel pins is to see what kind of plating you to chosen.

Plating refers to attaching a metal protective film on the surface of the metal material, which can prevent corrosion, prevent oxidation, make the appearance beautiful, and improve wear resistance, and so on.

We offer a variety of plating options, each with its own unique appearance. Whether your promotion requires a traditional and colorful appearance or a classic old-world look, you can choose the plating that best fits the occasion.

How To Choose Custom Lapel Pins Plating Options?

Which metal plating options are right for your custom pins? There is no right or wrong answer, it all depends on your pin design and preference.

If you are not sure which one goes best with your design, See the tip below.

Tips 1

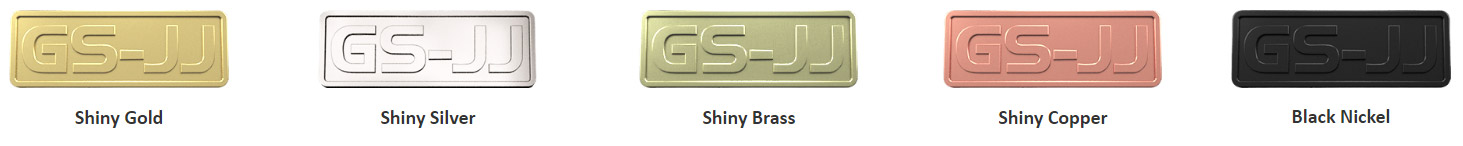

We can provide many different plating options are Shiny Gold, Shiny Silver, Shiny Copper, Shiny Brass, Black Nickel,

Alternative finishing options are Antique Gold, Antique Silver, Antique Brass, Antique Copper, Two-Tone Finish, Rainbow Plated and Black Dye.

.jpg)

Shiny Platings

Our shiny platings are the most common option for lapel pins. The pins are electroplated with your choice of Gold, Silver, Copper, or Black Nickel, Then buffed to a mirror shine. We suggest that this plating can be used with Soft Enamel Pins, Hard Enamel Pins, Sandblast Pins, and pins without enamel.

Antique Platings

Our antique metal platings are perfect for those who want a less flashy look to their pins. The finish subdues the metal so it isn’t as shiny and gives it a patina. Antique pins are a great contemporary look with old-world charm that is sure to impress.

The back of our antique pins is black. We suggest that this plating can be used with Antique pins, 3D or Cutout Pin, Soft enamel pins.

Rainbow Plated

We are excited to tell you that we can provide the rainbow metal pins. Their incredible eye-catching and vivid appearance will make your pins stand out from the crowd. You can add any color you like, It is definitely one of the coolest choices.

This process is called ” anodizing “

The rainbow effect is achieved by anodizing. First, the metal pin is cast in a mold. Before any enamel is added, the pin is carefully cleaned and prepared for the anodizing process. A chemical solution is created and pins are dipped in it.

The ground wire is connected to each pin, and the charge passes through the wire through the metal. The chemical reaction with electricity produces an amazing rainbow effect on the metal.

This process only takes a few seconds to change the color of the metal. Even if the power is turned on for half a second, the color of the metal can be greatly changed. The final color of metals is determined by the time it takes for the charge to pass through them. Then clean the pins with a chemical solution and add enamel if necessary.

Tips 2

This has been the biggest innovation and trend in the enamel pin movement recently. Enamel pin designers have been driving these changes within our industry and we couldn’t be happier.

Now you can get your base metal in white, red, green or blue. This has been the most exciting change we’ve seen in 46 years in this industry and solves a LOT of design problems.

Most pins are too small for us to inlay color in the text. White or black dyed metal solves the problem. Make your text raised metal when designing and advise us of your color choice.

This is not suitable for orders with a tight timeline as it adds a couple of extra steps to the electroplating process.

Tips 3

The two-tone finish can choose two or more kinds of finish together on a lapel pin. It should be noted that the plating of a lapel pin can only be shiny plating, or it can only be antique plating. You have to remember once your product is dye black plated, no other plating can be done.

Dye black lapel pins can only be dyed black. So if you choose a two-tone finish, we will recommend the plating of your lapel pins according to your requirements.

Tips 4

They both are black, but the plated black nickel is a kind of metallic bright black, bright and reflective, so it does not look particularly dark, and even looks like silvery when reflective. Dye black is to dye the whole product with black pigment, Because the pigment is dyed, the surface of the product is not particularly reflective and looks very dark. The disadvantage is that it is not as bright as a black nickel.

If you choose the Hard Enamel pin you cannot choose the antique finish type and dye black. In addition, for any other process, these plating are no different. Depending on what kind of metal color you like, you can choose what kind of plating.

Malaysia

Malaysia