Choosing the right metal fabrication service is one of the most crucial decisions you’ll make for the success of your structural project. Whether you are working on a commercial building, industrial infrastructure, or a custom metal structure, the quality and precision of the metalwork can make or break your project.

In this guide, we’ll walk you through the key factors to consider when selecting the ideal metal fabrication service to ensure that your structural project is completed on time, within budget, and to the highest standards.

When evaluating a metal fabrication service, experience is paramount. A company with years of experience in the industry will have the know-how to handle a variety of complex projects. However, it’s not just about the number of years—they should also have specific experience with structural projects similar to yours.

An experienced fabricator will not only be able to provide the right technical expertise but also offer valuable insights into potential challenges and solutions for your structural build.

Quality certifications are essential when selecting a metal fabrication service. A reputable company will adhere to industry standards to ensure the precision, safety, and durability of the structures they fabricate. Some common certifications to look for include:

These certifications guarantee that the fabricator follows strict quality control processes and is committed to delivering high-quality results.

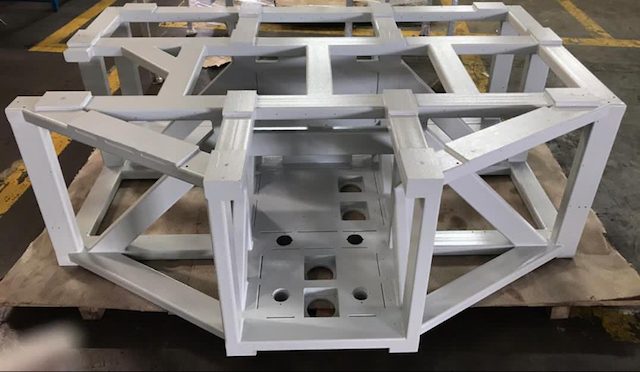

Metal fabrication for structural projects involves various steps, from designing and engineering to cutting, welding, and assembly. It’s essential to choose a service provider that offers a comprehensive range of services tailored to your project’s needs.

Having a fabricator who can handle multiple aspects of the project will ensure smoother communication and fewer delays during the process.

The latest fabrication technologies can significantly improve both the speed and quality of your project. Look for a metal fabrication service that uses state-of-the-art machinery and digital tools to achieve precision and efficiency. Key technologies that enhance fabrication include:

Advanced technology not only improves the final quality of the fabrication but also ensures that the project can be completed on time and within budget.

Effective communication is critical for the success of any structural project. A metal fabrication service that communicates clearly and consistently throughout the process will help you avoid misunderstandings, delays, and mistakes. This is especially true if your project involves complex designs or multiple stages of fabrication.

A fabricator with strong communication skills will keep you informed at every step and address any issues proactively, ensuring the project runs smoothly.

A solid portfolio of past projects is one of the best ways to assess the quality and capability of a metal fabrication service. Review their portfolio and client testimonials to see how well they have handled previous structural builds.

A trustworthy fabricator will be happy to showcase their past work and provide references from satisfied clients. This helps you gauge their ability to meet your project’s unique demands.

Every structural project comes with its own set of deadlines and milestones. To ensure your project stays on schedule, it’s important to choose a fabricator with the capacity to meet your timeline. This includes assessing whether they have the necessary staff, equipment, and resources to handle the scope of your project on time.

A reliable metal fabrication service should be able to give you a clear understanding of the expected timeline and show that they can meet deadlines without compromising on quality.

Price is a key consideration when selecting a metal fabrication service, but it should not be the only factor. Choosing a company based solely on price can lead to compromised quality and project delays. Instead, focus on getting value for your investment. Compare quotes from different fabricators and consider the following:

It’s essential to balance cost with quality and ensure that you’re getting a competitive price for the level of service and craftsmanship offered.

Metal fabrication, especially for structural projects, involves risks, and safety should always be a top priority. The right fabricator will adhere to all local and international safety standards and regulations to ensure that the work environment is safe and that the final product meets all legal and regulatory requirements.

Choosing the right metal fabrication service for your structural project is a critical decision that can significantly impact the success of your build. By focusing on factors such as experience, quality certifications, technological capabilities, and communication, you can select a fabricator that aligns with your project’s requirements and goals.

Take the time to thoroughly evaluate potential fabricators and ensure they can meet your timeline, budget, and quality expectations. With the right partner, your structural project will be in good hands from design through to final installation.

Singapore

Singapore