Discover the cutting-edge world of ultrasonic welding with our advance ultrasonic welders. These innovative machines harness the power of high-frequency vibrations to create strong and reliable bonds between materials. Whether you’re in manufacturing, electronics, automotive, or any other industry that demands precision welding, our ultrasonic welders are designed to elevate your production processes to new heights.

Area of Application

Ultrasonic Plastic Welding

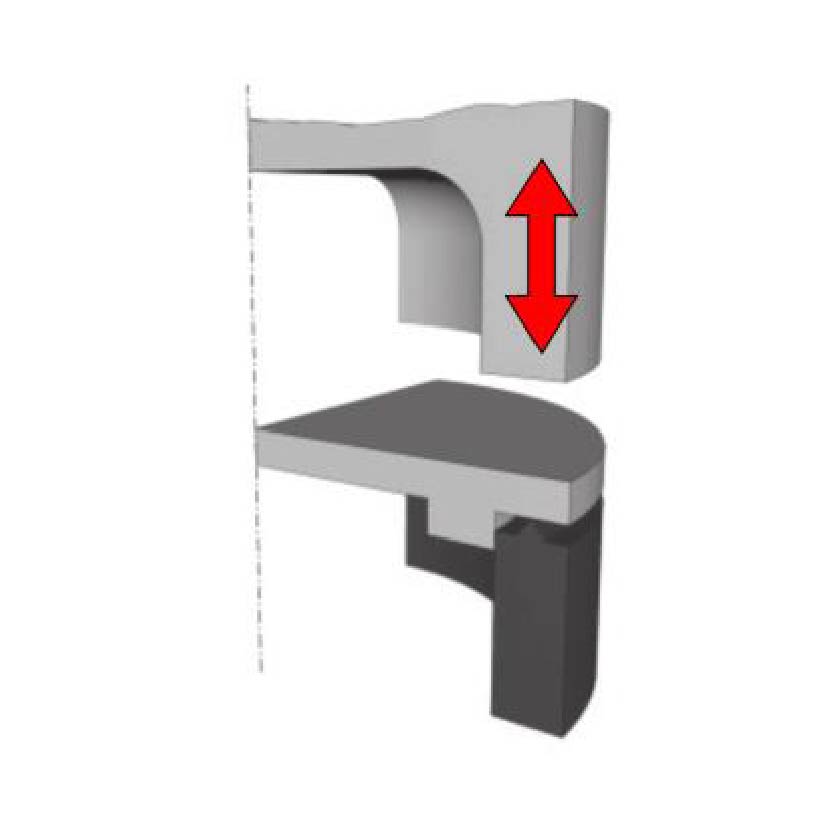

Riveting

Connections involving spot welding, riveting, and crimping are used in various applications, including interior linings, instrument panels, seats, and bumpers.

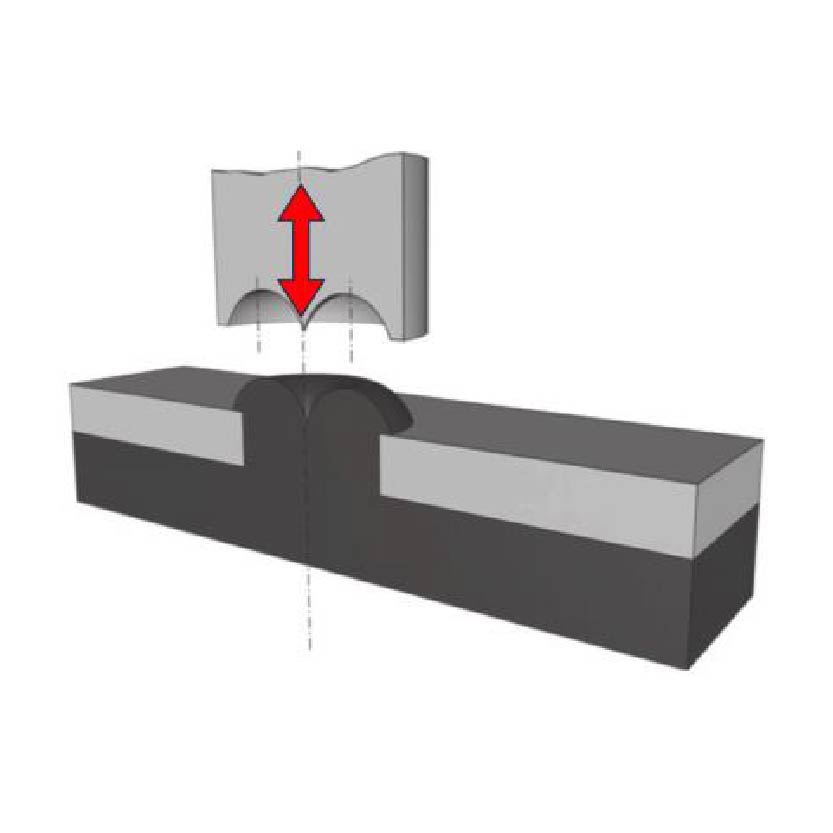

Welding

The primary role of the energy director is to swiftly initiate plasticization of the bonding surface by concentrating energy.

Ultrasonic Metal Welding

Ultrasonic Cutting

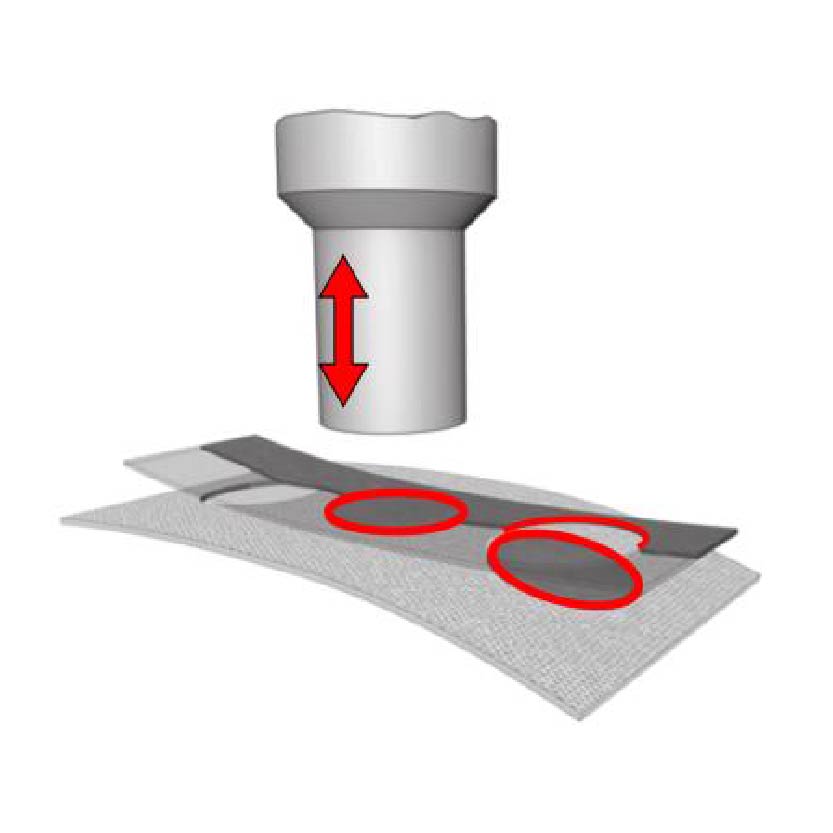

Cutting and Welding On

It allows for precise trimming of composite polymer and textile components, achieving the utmost cutting edge quality with flexibility.

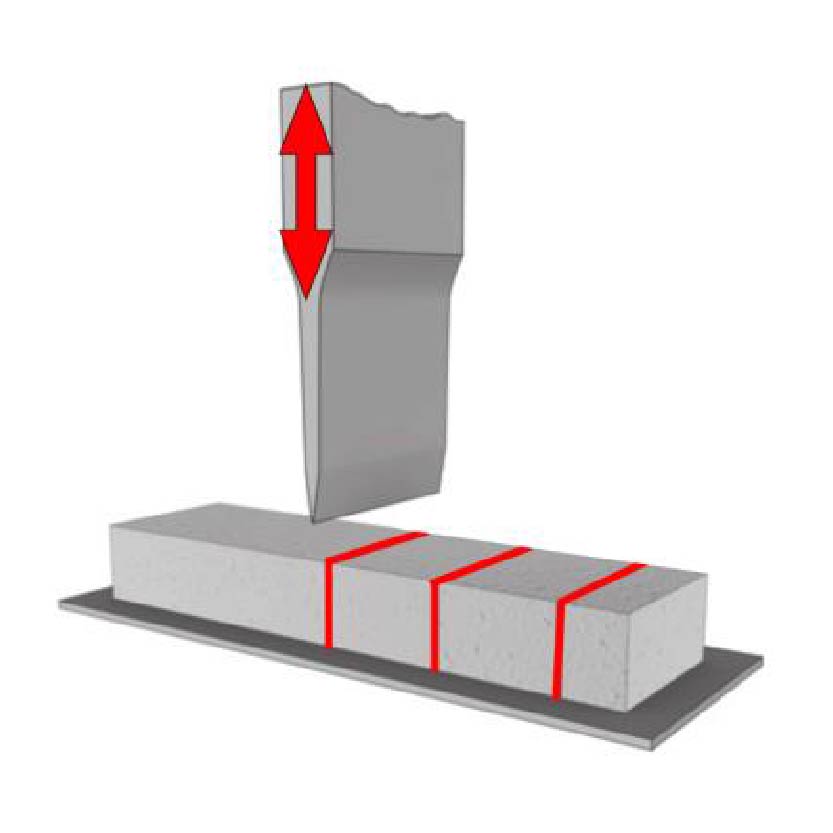

Separating Solids

The minimal cutting force ensures that the material being cut remains stable throughout the cutting process.

Singapore

Singapore