THE IMPORTANCE OF REGULAR CALIBRATION FOR WEIGHING SCALES

Weighing scales are essential tools used across various industries, including retail, healthcare, manufacturing, logistics, and scientific research. However, over time, even the most precise scales can drift from their original accuracy due to wear and tear, environmental factors, and frequent usage. Regular calibration is necessary to ensure accurate measurements, maintain compliance with industry regulations, and avoid costly errors. This article explores the importance of regular calibration, how often it should be performed, and best practices for maintaining accurate weighing scales.

Why Calibration is Essential

Ensures Accuracy and Reliability

Over time, weighing scales can experience deviations due to mechanical strain, temperature fluctuations, or improper handling.

Regular calibration corrects these deviations and ensures measurements remain accurate.

Compliance with Legal and Industry Standards

Many industries have strict regulations regarding weight measurements, such as food production, pharmaceuticals, and trade.

In Malaysia, businesses using scales for commercial transactions must adhere to the Weights and Measures Act 1972 and obtain verification from authorized bodies.

Prevents Financial Losses

Incorrect weighing can lead to overcharging or undercharging customers, affecting business reputation and revenue.

Manufacturing errors caused by inaccurate scales can result in product recalls, waste, and inefficiencies.

Enhances Product Quality and Consistency

In industries such as food production and pharmaceuticals, precise measurements ensure consistent product quality and safety.

Calibration helps maintain uniformity in production, reducing variations and defects.

Extends the Lifespan of Weighing Equipment

Routine calibration and maintenance can identify early signs of wear and prevent costly repairs or replacements.

Properly maintained scales perform better and last longer, providing better return on investment.

How Often Should Weighing Scales Be Calibrated?

The frequency of calibration depends on several factors, including:

Usage Frequency: Heavily used scales require more frequent calibration.

Industry Requirements: Some industries have mandatory calibration schedules (e.g., annual verification for trade scales in Malaysia).

Environmental Conditions: Exposure to extreme temperatures, vibrations, or humidity may affect scale accuracy and necessitate frequent calibration.

Type of Scale: High-precision analytical balances require more frequent calibration compared to standard retail scales.

A general guideline for calibration frequency:

Daily/Before Use: Quick accuracy checks using test weights.

Monthly/Quarterly: Internal calibration if the scale has an auto-calibration feature.

Annually: Professional calibration and verification by certified metrology authorities.

Best Practices for Maintaining Calibration Accuracy

Use Certified Calibration Weights

Ensure calibration weights comply with international standards (e.g., OIML or ASTM-certified weights).

Calibrate in a Stable Environment

Avoid calibration in areas with excessive vibrations, airflow, or temperature fluctuations.

Keep Scales Clean and Properly Stored

Dust, debris, and moisture can affect scale performance.

Store scales on a level surface and away from direct sunlight.

Schedule Professional Calibration Services

Engage authorized service providers, such as Metrology Corporation Malaysia (MCM) or the National Metrology Institute of Malaysia (NMIM), for official verification and stamping.

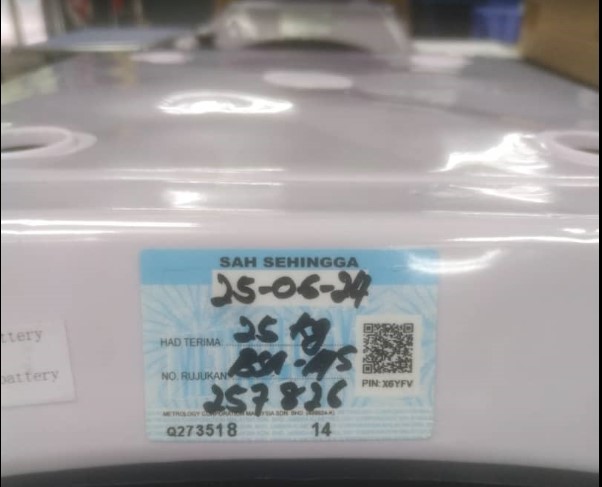

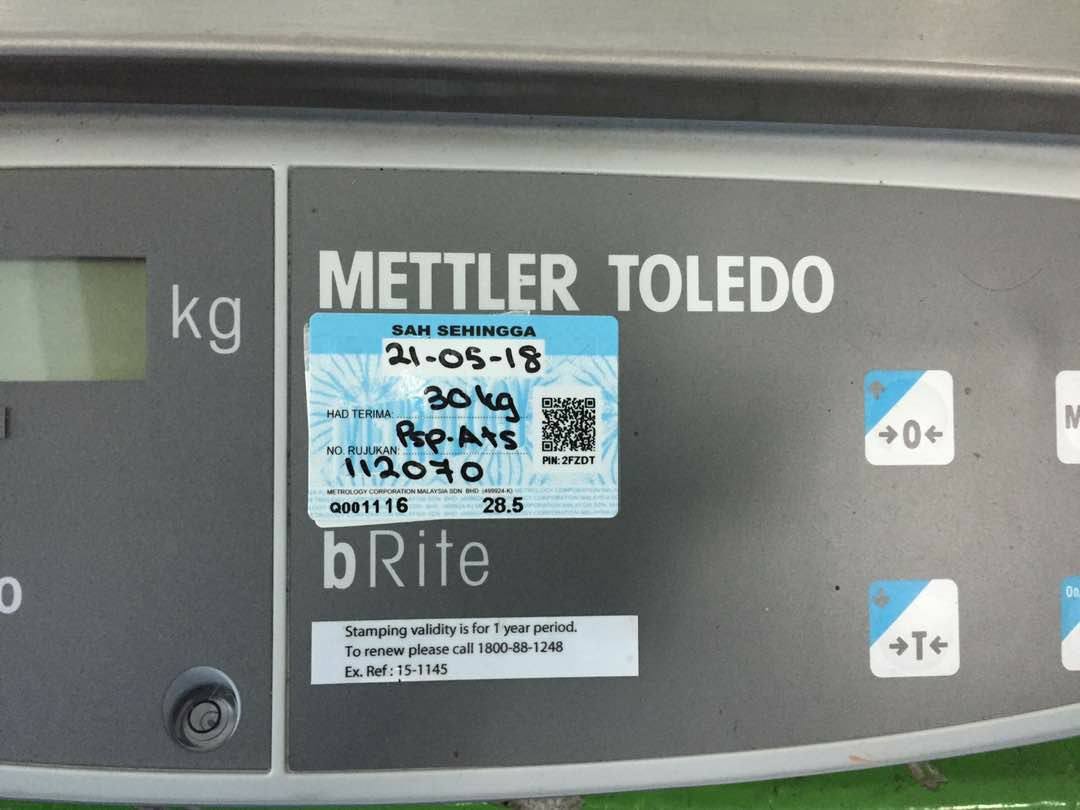

Sample Metrology License / Stamping:

Monitor Scale Performance

If discrepancies appear in measurements, recalibrate immediately to avoid incorrect readings.

Conclusion

Regular calibration is a crucial practice for businesses and industries relying on precise weight measurements. Ensuring accuracy enhances product quality, prevents financial losses, and maintains compliance with legal standards. By following best practices and scheduling routine calibration, businesses can extend the lifespan of their weighing equipment and uphold customer trust. For expert calibration services, always consult certified professionals to guarantee optimal performance and regulatory compliance.

Singapore

Singapore