Because PP is the lightest of general-purpose plastics and has superior chemical resistance, it is used in a wide variety of industrial fields.

| Grade | Characteristics |

|---|---|

| PP(NC) | Standard grade |

* Refer to the Products Catalogue on page 44 for product specifications.

| Category | Property | Unit | Test Method ISO | TPS® PP |

|---|---|---|---|---|

| NC | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 29 |

| Tensile elasticity | % | >200 | ||

| Bending strength | MPa | 178 | - | |

| Bending elasticity | GPa | - | ||

| Poisson’s ratio | - | - | 0.4 | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 5.0 | |

| Rockwell hardness | - | - | R85 | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 0.91 |

| Water absorption (23°C, 24 Hrs) | % | - | <0.03 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 11 | |

| Flammability (UL) | - | UL94 | - | |

| Thermal properties | Deflection temperature under load (0.45MPa) | °C | 75-1,2 | 80 |

| Continuous use temperature | °C | - | - | |

| Glass transition temperature | °C | - | - | |

| Melting point | °C | - | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - |

| Surface resistance | Ω | IEC60093 | - | |

| Volume resistance | Ω・cm | - | ||

| Permittivity 106Hz | - | IEC60250 | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | |

| Certified per the Food Sanitation Act | ◯ | |||

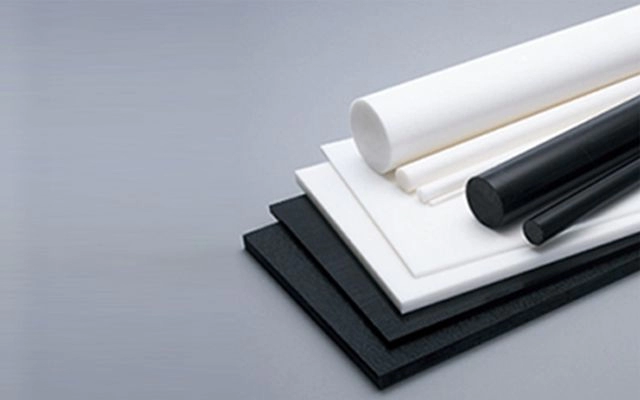

Nylon (polyamide) is a crystalline plastic with superior mechanical properties, and has superior abrasion/wear resistance, chemical resistance (excluding mineral acids, phenols and the like) and oil resistance, as well as excellent performance as a gas barrier.

Nylon has a high melting point and high water absorption due to its chemical structure. The flexibility and impact resistance of nylon improves when it absorbs water. Nylon 66 has lower water absorption and higher rigidity compared to nylon 6.

| Grade | Characteristics |

|---|---|

| N6(NC) | Standard grade(unfilled) |

| N6(M) | Wear-resistant grade (molybdenum disulfide added) |

| N6(G30 BK) | Fiberglass reinforced grade |

| N66(NC) | Standard grade(unfilled) |

| N66(G30 BK) | Fiberglass reinforced grade |

* Refer to the Products Catalogue on pages 41 for product specifications.

| Category | Property | Unit | Test Method ISO | TPS® N6 | TPS® N66 | ||

|---|---|---|---|---|---|---|---|

| NC | G30 | NC | G30 | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 75 | 185 | 85 | 160 |

| Tensile elasticity | % | 50< | 11 | 50< | 3.0 | ||

| Bending strength | MPa | 178 | 100 | 285 | 110 | - | |

| Bending elasticity | GPa | 2.5 | 9.4 | 2.7 | - | ||

| Poisson’s ratio | - | - | 0.38 | 0.35 | 0.3 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 5.5 | 15.0 | 4.5 | 70.0 | |

| Rockwell hardness | - | - | - | - | - | R121 | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.13 | 1.36 | 1.14 | 1.35 |

| Water absorption (23°C, 24 Hrs) | % | - | 1.8 | - | - | 0.6 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | - | 2.5 | 8.0 | 2~3 | |

| Flammability (UL) | - | UL94 | HB (0.75mm) |

HB Equivarent | HB (0.71mm) |

HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | - | 205 | 70 | 250 |

| Continuous use temperature | °C | - | - | 100 | - | 110 | |

| Glass transition temperature | °C | - | - | 40~60 | 40~60 | 50 | |

| Melting point | °C | - | 225 | 215~225 | 255~265 | 255 | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - | - | 20.0 | - |

| Surface resistance | Ω | IEC60093 | - | - | - | - | |

| Volume resistance | Ω・cm | - | 1015 | 1015 | - | ||

| Permittivity 106Hz | - | IEC60250 | - | - | - | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | - | - | - | |

| Certified per the Food Sanitation Act | ◯ | - | ◯ | - | |||

PC is the only engineering plastic that is transparent. It is a non-crystalline plastic with outstanding impact resistance and can be used under a broad range of temperatures. PC also has superior creep resistance, and because of its low water absorption, has excellent dimension stability. Its electrical properties are also extremely good, but because of its low resistance to chemicals and propensity for stress cracks, care must be exercised.

| Grade | Characteristics |

|---|---|

| PC (NC)-I | Standard grade(transparent, ice-color) |

| PC (BK) | Standard grade(black, light-proof) |

| PC (G20BK) | Glass-reinforced grade |

* Refer to the Products Catalogue on page 43 for product specifications.

| Category | Property | Unit | Test Method ISO | TPS® PC | |

|---|---|---|---|---|---|

| NC-I | BK | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 75 | 65 |

| Tensile elasticity | % | 50< | 50< | ||

| Bending strength | MPa | 178 | 91 | 100 | |

| Bending elasticity | GPa | 2.3 | 2.3 | ||

| Poisson’s ratio | - | - | - | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | ≧65.0 | ≧5.0 | |

| Rockwell hardness | - | - | - | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.20 | 1.20 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.20 | 0.20 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 6.5 | 6.5 | |

| Flammability (UL) | - | UL94 | V-2 (0.40mm) |

V-2 (0.40mm) |

|

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 130 | 130 |

| Continuous use temperature | °C | - | 115 | 115 | |

| Glass transition temperature | °C | - | 130~150 | 130~150 | |

| Melting point | °C | - | - | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | 30.0 | 30.0 |

| Surface resistance | Ω | IEC60093 | 1015 | 1015 | |

| Volume resistance | Ω・cm | 1013 | 1013 | ||

| Permittivity 106Hz | - | IEC60250 | 3.10 | 3.10 | |

| Dielectric tangent 106Hz | - | IEC60250 | 0.0090 | 0.0090 | |

| Certified per the Food Sanitation Act | ○ | ○ | |||

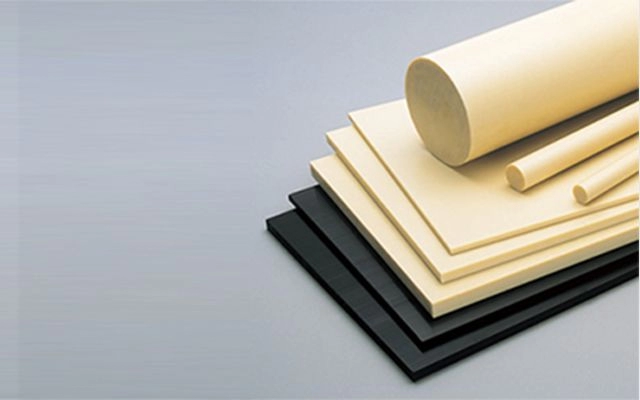

PBT is the newest crystalline plastic among engineering plastics, and has high toughness and rigidity, as well as superior resistance to heat aging (it maintains good mechanical properties even under high temperatures).

PBT also has good electrical properties under a broad range of temperatures. It has low water absorption, excellent climate and chemical resistance, and is well-balanced.

| Grade | Characteristics |

|---|---|

| PBT(NC) | Standard grade |

| PBT(G30NC) | Fiberglass reinforced grade |

* Refer to the Products Catalogue on page 42 for product specifications.

| Category | Property | Unit | Test Method ISO | TPS® PBT | |

|---|---|---|---|---|---|

| NC | G30 NC |

||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 53 | 135 |

| Tensile elasticity | % | 108.0 | 3.0 | ||

| Bending strength | MPa | 178 | - | - | |

| Bending elasticity | GPa | 2.44 | - | ||

| Poisson’s ratio | - | - | 0.35 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 3.9 | - | |

| Rockwell hardness | - | - | - | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.31 | 1.53 |

| Water absorption (23°C, 24 Hrs) | % | - | - | 0.15 | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | - | 2~3 | |

| Flammability (UL) | - | UL94 | HB Equivarent | HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 59 | 210 |

| Continuous use temperature | °C | - | - | 110 | |

| Glass transition temperature | °C | - | 35 | 60 | |

| Melting point | °C | - | 223 | 225 | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | - | 50.0 |

| Surface resistance | Ω | IEC60093 | - | 1015 | |

| Volume resistance | Ω・cm | - | - | ||

| Permittivity 106Hz | - | IEC60250 | - | 3.8 | |

| Dielectric tangent 106Hz | - | IEC60250 | - | 0.009 | |

| Certified per the Food Sanitation Act | - | - | |||

PPS is a crystalline plastic with high heat resistance (continuous use temperature of approximately 220°C) and superior mechanical strength, rigidity, flame resistance, chemical resistance, electrical properties and dimensional stability. The market for PPS has recently been expanding rapidly, taking advantage of its superior characteristics.

The primary uses of PPS is as electric/electronic components, automobile components, mechanical components (e.g., chemical pump), and components for semiconductor/liquid crystal manufacturing and testing equipment.

| Grade | Characteristics |

|---|---|

| PPS (NC) SC | Standard grade(unfilled) |

| PPS (G40BK) | Fiberglass reinforced grade(black) |

| PPS 230-AE3 | AE grade (conductive) |

| PPS 2001 | High-function sheets (unfilled grade with a thickness of 0.2 to 2 mm) |

* Refer to the Products Catalogue on page 36 for product specifications.

| Category | Property | Unit | Testing Method ASTM | TPS® PPS | ||

|---|---|---|---|---|---|---|

| NC-SC | G40 | 230-AE3 | ||||

| BK | ||||||

| Mechanical properties | Tensile strength | MPa | D638 | 79 | 167 | 98 |

| Tensile elasticity | % | 23.0 | 2.0 | 5.0 | ||

| Bending strength | MPa | D790 | 128 | 235 | 150 | |

| Bending elasticity | GPa | 3.3 | 11.8 | 6.2 | ||

| Poisson’s ratio | - | - | 0.37 | 0.4 | - | |

| Compressive strength | MPa | D695 | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 15 | 157 | 45 | |

| Rockwell hardness | - | D785 | - | M80 | M98 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.35 | 1.59 | 1.40 |

| Water absorption (23°C, 24 Hrs) | % | D570 | 0.02 | 0.02 | 0.02 | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 2.4~2.9 | 1.7~6.8 | - | |

| Thermal conduction | W/mK | E 1530 | 0.20 | - | - | |

| Flammability (UL) | - | D570 | V-0 equivalent | V-2 (0.8mm) |

V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 112 | 260 | 173 |

| Continuous use temperature | °C | - | 220 | 220 | 220 | |

| Glass transition temperature | °C | - | 88 | - | 88 | |

| Melting point | °C | - | 278 | - | 278 | |

| Electrical properties | Dielectric strength | MV/m | D149 | 15.0 | 18.0 | - |

| Surface resistance | Ω | D257 | 1016 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | 1018 | 1016 | - | ||

| Permittivity 106Hz | - | D150 | 3.6 | 4.1 | - | |

| Dielectric tangent 106Hz | - | 0.0011 | 0.003 | - | ||

| Certified per the Food Sanitation Act | ◯ | - | - | |||

_Material_.png)

| Category | Property | Unit | Testing Method ASTM | TI530-AE3 | PEEK 430-AE3 |

PPS 230-AE3 |

|---|---|---|---|---|---|---|

| Mechanical properties | Tensile strength | MPa | D638 | 100 | 98 | 98 |

| Tensile elasticity | % | 3.5 | 4.0 | 5.4 | ||

| Bending strength | MPa | D790 | 137 | 160 | 150 | |

| Bending elasticity | GPa | 10.8 | 4.2 | 6.2 | ||

| Poisson’s ratio | - | - | - | - | - | |

| Compressive strength | MPa | D695 | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 37 | 39 | 45 | |

| Rockwell hardness | - | D785 | M95 | M100 | M98 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.55 | 1.33 | 1.40 |

| Water absorption (23°C, 24 Hrs) | % | D570 | - | - | 0.02 | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 1.3 | 3.5 | - | |

| Thermal conduction | W/mK | E 1530 | - | - | - | |

| Flammability (UL) | - | D570 | V-0 (0.75mm) |

V-0 equivalent | V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 280 | 164 | 173 |

| Continuous use temperature | °C | - | 250 | 260 | 220 | |

| Glass transition temperature | °C | - | 280 | 143 | 88 | |

| Melting point | °C | - | - | 343 | 278 | |

| Electrical properties | Dielectric strength | MV/m | D149 | - | - | - |

| Surface resistance | Ω | D257 | 101~6 | 101~6 | 101~6 | |

| Volume resistance | Ω・cm | 101~6 | 101~6 | - | ||

| Permittivity 106Hz | - | D150 | - | - | - | |

| Dielectric tangent 106Hz | - | - | - | - | ||

| Certified per the Food Sanitation Act | - | - | - | |||

The primary uses for PEEK are as semiconductor/liquid crystal manufacturing equipment components, testing equipment components, medical equipment components and the like.

| Grade | Characteristics |

|---|---|

| PEEK(NC) | Standard grade |

| PEEK430-AE3 | AE grade (conductive) |

| PEEK 4000 | High-function sheets (unfilled grade with a thickness of 0.1 to 0.5 mm) |

| PEEK 4110 | High-function sheets (high-sliding grade with a thickness of 0.1 to 0.5 mm) |

* Refer to the Products Catalogue on page 35 for product specifications.

| Category | Property | Unit | Testing Method ASTM | TPS® PEEK | |

|---|---|---|---|---|---|

| NC | 430-AE3 | ||||

| Mechanical properties | Tensile strength | MPa | D638 | 98 | 98 |

| Tensile elasticity | % | >60 | 4.0 | ||

| Bending strength | MPa | D790 | 170 | 160 | |

| Bending elasticity | GPa | 4.2 | 4.2 | ||

| Poisson’s ratio | - | - | 0.4 | - | |

| Compressive strength | MPa | D695 | 118 | - | |

| Izod impact strength (notched) | J/m | D256 | 67 | 39 | |

| Rockwell hardness | - | D785 | M99 | M100 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.32 | 1.33 |

| Water absorption (23°C, 24 Hrs) | % | D570 | 0.5 | - | |

| Linear expansion coefficient | ×10-5 /°C |

JIS K7197 | 4.7~10.8 | 3.5 | |

| Thermal conduction | W/mK | E 1530 | 0.26 | - | |

| Flammability (UL) | - | D570 | V-0 (1.5mm) |

V-0 equivalent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 152 | 164 |

| Continuous use temperature | °C | - | 260 | 260 | |

| Glass transition temperature | °C | - | 143 | 143 | |

| Melting point | °C | - | 343 | 343 | |

| Electrical properties | Dielectric strength | MV/m | D149 | - | - |

| Surface resistance | Ω | D257 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | 1016 | 101~6 | ||

| Permittivity 106Hz | - | D150 | - | - | |

| Dielectric tangent 106Hz | - | - | - | ||

| Certified per the Food Sanitation Act | ◯ | - | |||

| Grade | Characteristics |

|---|---|

| POM (NC), (BK) | Standard grade (Natural color, Black) |

| POM (NC), (BK)Super | Low-warp grade (Natural color, Black) |

| POM (G25NC) | Fiberglass reinforced grade |

| POM 131-AE3 | AE grade (conductive) |

* Refer to the Products Catalogue on pages 37 through 40 for product specifications.

| Category | Property | Unit | Test Method ISO | TPS® POM | ||

|---|---|---|---|---|---|---|

| NC・BK | G25 | 131-AE3 | ||||

| Mechanical properties | Tensile strength | MPa | 527-1,2 | 57 | 136 | 59 |

| Tensile elasticity | % | 40.0 | 3.0 | 16.0 | ||

| Bending strength | MPa | 178 | 76 | 200 | 87 | |

| Bending elasticity | GPa | 2.2 | 7.9 | 2.4 | ||

| Poisson’s ratio | - | - | 0.35 | 0.38 | - | |

| Charpy impact strength (notched) | KJ/m2 | 179/1eA | 8.5 | 8.0 | 5.4 | |

| Rockwell hardness | - | - | M78 | M79 | - | |

| Physical properties | Density (23°C) | g/cm3 | 1183 | 1.41 | 1.59 | 1.42 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.22 | 0.29 | - | |

| Linear expansion coefficient | ×10-5 /°C |

11359-2 | 10 | 3~9 | - | |

| Flammability (UL) | - | UL94 | HB (0.75mm) |

HB (0.81mm) |

HB Equivarent | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | 75-1,2 | 110 | 162 | - |

| Continuous use temperature | °C | - | 100 | 105 | - | |

| Glass transition temperature | °C | - | -60 | - | - | |

| Melting point | °C | - | 163 | 165 | - | |

| Electrical properties | Dielectric strength (3mm) | kV/mm | IEC60243-1 | 19.0 | 24.0 | - |

| Surface resistance | Ω | IEC60093 | 1016 | 1016 | 101~6 | |

| Volume resistance | Ω・cm | - | 1014 | 101~6 | ||

| Permittivity 106Hz | - | IEC60250 | - | - | - | |

| Dielectric tangent 106Hz | - | IEC60250 | - | - | - | |

| Certified per the Food Sanitation Act | ◯ | - | - | |||

| Grade | Characteristics |

|---|---|

| ABS (NC), (BK), (WH) | Standard grade (natural color, black, white) |

| ABS (NC), (BK) Super | Low-warping grade (natural color, black) |

* Refer to the Products Catalogue on pages 43 to 44 for product specifications.

| Category | Property | Unit | Testing Method ASTM | TPS® ABS |

|---|---|---|---|---|

| NC ・ BK | ||||

| Mechanical properties | Tensile strength | MPa | D638 | 45 |

| Tensile elasticity | % | 50< | ||

| Bending strength | MPa | D790 | 65 | |

| Bending elasticity | GPa | 2.1 | ||

| Poisson’s ratio | - | - | - | |

| Izod impact strength (notched) | J/m | D256 | 275 | |

| Rockwell hardness | - | - | R100 | |

| Physical properties | Specific gravity (23°C) | - | D792 | 1.04 |

| Water absorption (23°C, 24 Hrs) | % | - | 0.3 | |

| Linear expansion coefficient | ×10-5/°C | D696 | 8.3 | |

| Flammability (UL) | - | UL94 | - | |

| Thermal properties | Deflection temperature under load (1.82 MPa) | °C | D648 | 86 |

| Continuous use temperature | °C | - | 55 | |

| Glass transition temperature | °C | - | - | |

| Melting point | °C | - | - | |

| Electrical properties | Dielectric strength | MV/m | D149 | - |

| Surface resistance | Ω | D257 | - | |

| Volume resistance | Ω・cm | - | ||

| Permittivity 106Hz | - | D150 | - | |

| Dielectric tangent 106Hz | - | D150 | - | |

| Certified per the Food Sanitation Act | - | |||

Vietnam

Vietnam